- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

600

-

Voltage:

-

380V/220V/110V

-

Current:

-

10A

-

Rated Capacity:

-

3600

-

Rated Duty Cycle:

-

100

-

Dimensions:

-

1.5*0.7*1.3

-

Usage:

-

auto welding

-

laser source:

-

JPT IPG RECI Raycus

-

Laser power:

-

1000W, 1500W, 2000W

-

Control system:

-

RAYTOOLS REFAIR QINLIN

-

Welding gun:

-

RAYTOOLS REFAIR QINLIN

-

Cable length:

-

10-15MM

-

Wavelength:

-

1080nm

-

Pulse Width:

-

50 μm

Quick Details

-

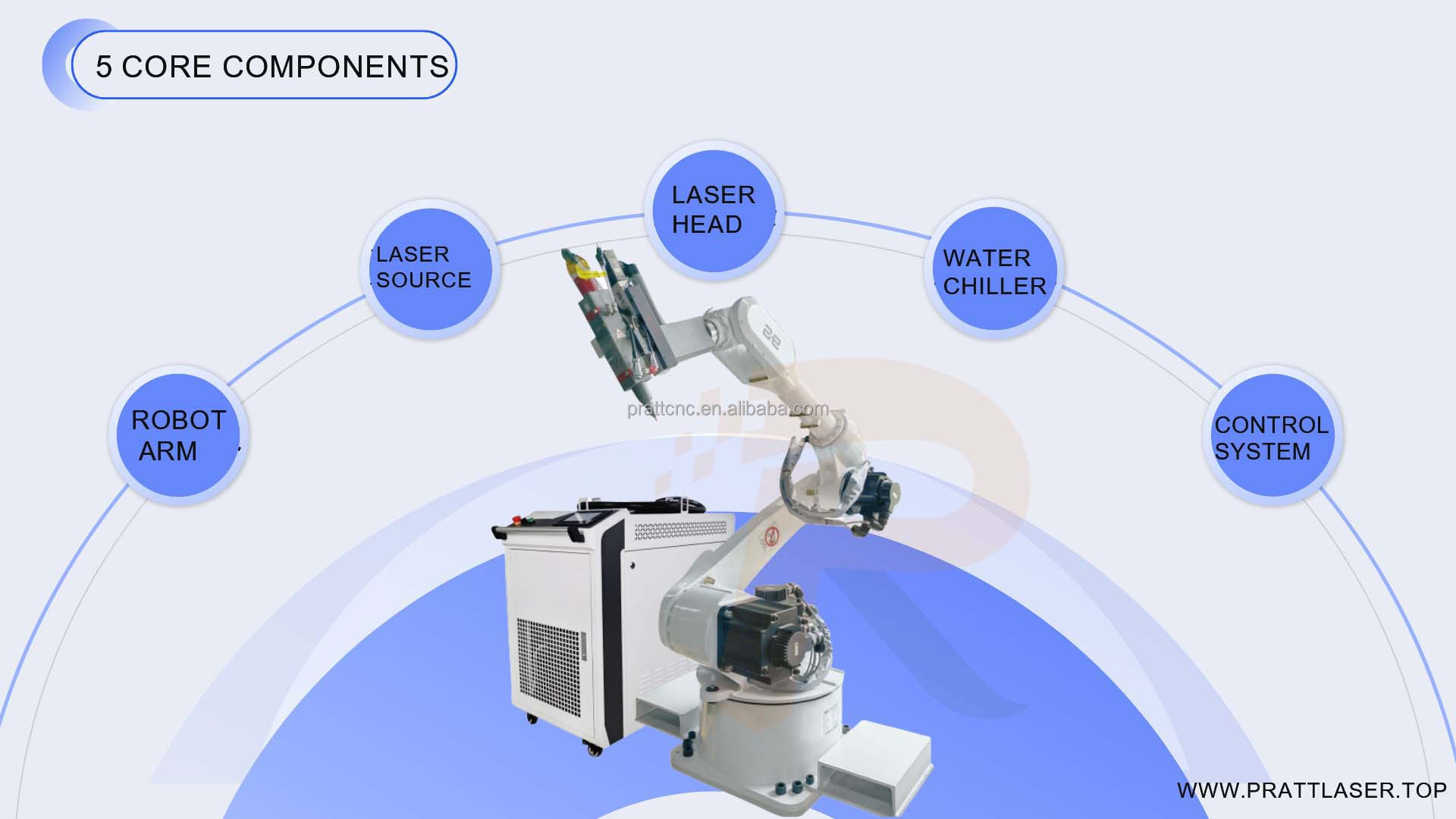

Core Components:

-

laser source

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

pratt

-

Weight (KG):

-

600

-

Voltage:

-

380V/220V/110V

-

Current:

-

10A

-

Rated Capacity:

-

3600

-

Rated Duty Cycle:

-

100

-

Dimensions:

-

1.5*0.7*1.3

-

Usage:

-

auto welding

-

laser source:

-

JPT IPG RECI Raycus

-

Laser power:

-

1000W, 1500W, 2000W

-

Control system:

-

RAYTOOLS REFAIR QINLIN

-

Welding gun:

-

RAYTOOLS REFAIR QINLIN

-

Cable length:

-

10-15MM

-

Wavelength:

-

1080nm

-

Pulse Width:

-

50 μm

Six-axis robot welding/automatic welding/cleaning machine

This machine adopts fiber laser welding head. The fiber laser welding head can realize six-axis simultaneous welding. The system can be switched freely according to different application scenarios, providing diversified solutions for different application requirements of users. Suitable for welding base, high complexity welding.

Advantages of Pratt CNC robot laser welding machine

1. The optical fiber welding workpiece is flexible, up to 3 meters long.

2. The weld seam is smooth and beautiful, without grinding or only a little grinding.

3. It is suitable for various welding processes such as spot welding, seam welding and lap welding.

4. Non-contact cleaning for metal rust removal, paint removal, oil removal and dirt removal.

5. Easy to cut metal for optional use.

6. The use of program-controlled robots can weld sharp parts according to specific procedures, and can cut metals of specific shapes.

7. The operation is simple and does not require traditional professional welders.

8. You don't need to wear a mask, you can wear laser protective glasses.

9. Low cost of use. Low power consumption, low gas consumption and low lens consumption.

Parameter

|

Model |

PRW1000CW |

PRW1500CW |

PRF2000CW |

PRF3000CW |

|

Laser Power |

1000W |

1500W |

2000W |

3000W |

|

Welding depth (SS) |

2.68mm |

3.59mm |

4.57mm |

6.87mm |

|

Welding depth (CS) |

2.06mm |

2.77mm |

3.59mm |

4.79mm |

|

Welding depth (Al) |

2mm |

3mm |

4mm |

6mm |

|

Feeding Wires' Dimenson |

0.8-1.2 wire |

0.8-1.6 wire |

0.8-1.6 wire |

0.8-2.0 wire |

|

Max Cleaning Width |

40mm |

40mm |

40mm |

40mm |

|

Laser Wavelength |

1070 +/-10 nm |

1070 +/-10 nm |

||

|

Laser Frenquency |

50-5000HZ |

50-5000HZ |

||

|

Position System |

Red Light Indicator |

Red Light Indicator |

||

|

Power Adjustment |

10-100% |

10-100% |

||

|

Cooling Method |

Water Chiller |

Water Chiller |

||

|

Spot Size |

1.2-3.0mm (option) |

1.2-3.0mm (option) |

||

|

Power Instability |

<3% |

<3% |

||

|

Shielding Gas Flow |

15-20 L/min (Ar Or N) |

15-20 L/min (Ar Or N) |

||

|

Power Supply |

220V 50&60HZ |

380V /50&60HZ |

||

|

Size(L*W*H) CM |

90*40*70 |

90*40*70 |

115*65*87 |

|

|

Net Weight |

160KG |

170KG |

180KG |

220KG |

|

Total Power Consumption |

≤3KW |

≤4.5KW |

≤6KW |

≤9KW |

|

Parameter |

Tig Welding |

Laser Welding |

|

Heat |

Very high |

Very low |

|

Deformation |

Easy to deform |

No deformation |

|

Processing time |

Long |

Short |

|

Welding Workload |

2 professional welders |

1 operator |

|

Exterior |

Unsightly, need polishing |

Smooth and beautiful, polishing free |

|

Welding spot |

Large welding spot |

Fine welding spot, adjustable |

|

Perforation |

Easy to pierce |

Not easy to perforate, controllable |

|

Protective gas |

Need argon or N |

Need argon or N |

|

Precision |

General |

Precision |

|

Power consumption |

High |

Low |

|

Safety |

Ultraviolet light, radiation |

Radiation-free |

Environmental protection advantages : Laser cleaning is a "green" cleaning method, without the use of any chemicals or cleaning

cause pollution. Can easily solve the environmental pollution problems caused by chemical cleaning. Often a single exhaust fan can

solve the problem of waste generated by cleaning.

Effect advantages: The traditional cleaning method is often contact cleaning, which has mechanical force on the surface of the cleaning object, the surface of the damaged object or the cleaning medium is attached to the surface of the object to be cleaned,and cannot be removed, resulting in secondary pollution. Grinding and non-contact, no thermal effects will not damage the substrate, making these problems solved.

Convenient advantage: laser cleaning can remove various types of contaminants on the surface of various materials, reaching a degree of cleanliness that cannot be achieved by conventional cleaning. It can also selectively clean contaminants on the surface of the material without damaging the surface of the material.

Cost advantage: laser cleaning speed is fast, high efficiency, save time; although the initial investment of the laser cleaning system is high, the cleaning system can be used for a long time and stable, the operating cost is low, and more importantly, it can be easily automated. Cost calculation: single cleaning efficiency of 8 square meters per hour per hour operating cost is about 5 kWh electricity cost, that is, the cleaning cost is 4 cents per square meter, except for the initial cost, the latter 4 cents per square meter.

Control advantages: The laser can be transmitted through the optical fiber, cooperate with the robot hand and the robot, conveniently realize long-distance operation, and can clean the parts that are difficult to reach by traditional methods, which