- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 year

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

JIN HENG TAI

-

Model Number:

-

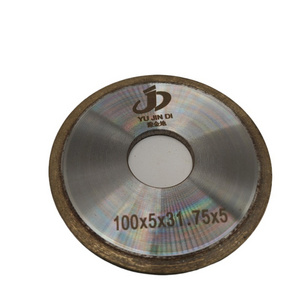

MD2 125X20X5X4

-

Supply Ability:

-

20000 Pieces/Month

-

Speed:

-

45m/s

-

Material:

-

Diamond + Aluminum Base

-

Product name:

-

Cutting Disc

-

Packing:

-

Carton

-

MOQ:

-

300g

-

Body Material:

-

Alumium

-

Diameter:

-

125mm

-

Grit Size:

-

240# 320# 400#

Quick Details

-

Application:

-

Deburring

-

Shape:

-

Dish

-

Size:

-

MD2 125X20X5X4

-

Warranty:

-

1 year

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

JIN HENG TAI

-

Model Number:

-

MD2 125X20X5X4

-

Supply Ability:

-

20000 Pieces/Month

-

Speed:

-

45m/s

-

Material:

-

Diamond + Aluminum Base

-

Product name:

-

Cutting Disc

-

Packing:

-

Carton

-

MOQ:

-

300g

-

Body Material:

-

Alumium

-

Diameter:

-

125mm

-

Grit Size:

-

240# 320# 400#

Overview

Product video d

escription

Product Description

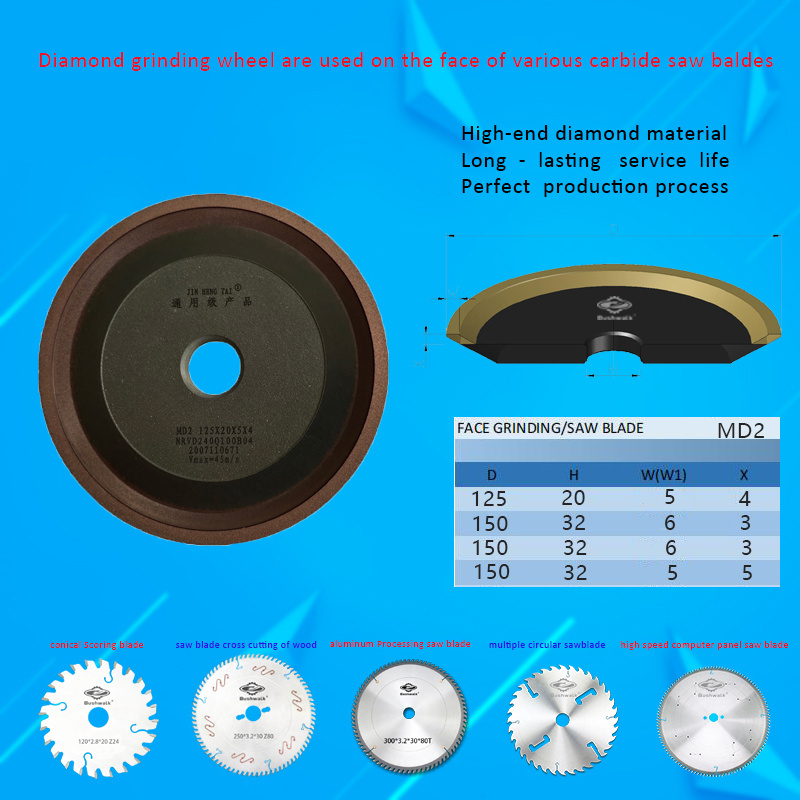

Diamond Grinding Wheel

125mm (5in) resin bonded diamond grinding wheel

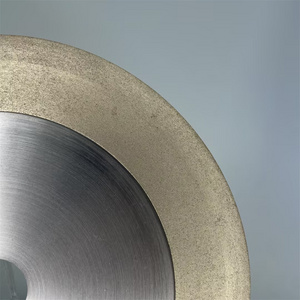

Resin bond diamond grinding wheel was divided into two parts, diamond working layer and aluminum matrix, working layer was combination by diamond powder and resin bond (resin powder and other mixed powder), and after fillers pressed under heat and pressure, solidify, then, firmly combined aluminum matrix, with a certain shape of diamond grinding tool.

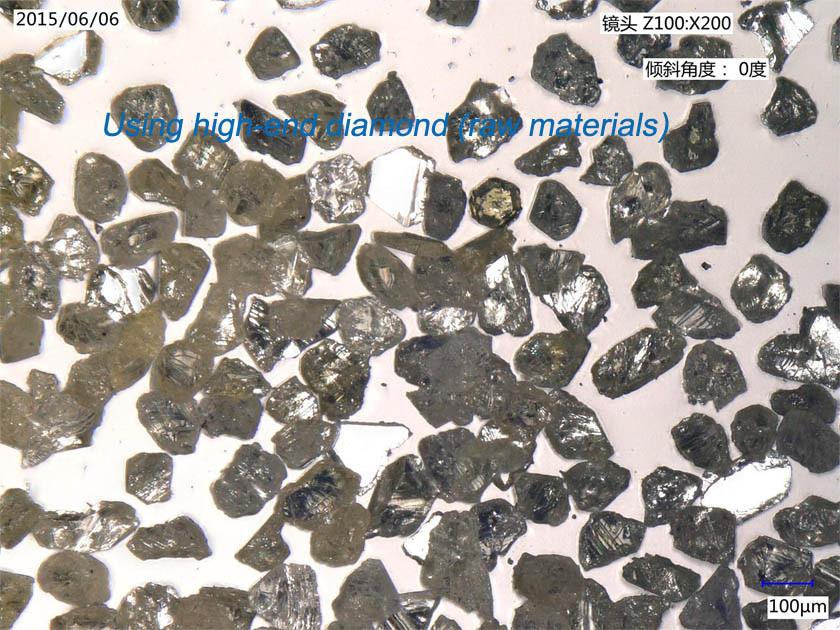

Diamond materials

Side view

Product Advantage

1.High-quality raw material of synthetic diamond powder, which is manufactured by our own factory;2.

2.

High grinding efficiency, long working life;

3.

Good self-sharpening, lower grinding temperature, less blocking, less

workpiece

surface burn ;

4.

Grinding wheel has a certain elasticity, improving the surface roughness, used for grinding, semi-finish grinding, polishing,and other processes;

5.

The diamond grinding wheel is a shorter production cycle time, higher removal rate. Easily to make complex wheels;

6. The company has professional technology and equipment, easier to form a variety of complex surface resin diamond grinding wheels.

Application

Sharpening diagram

Diamond grinding wheel sharpens the face angle , top angel and side angel of the saw blade.

HARD grinding machine-face

HARD grinding machine-top

HARD grinding machine-side

VOLLMER grinding machine-face

VOLLMER grinding machine-side

TORSEL grinding machine-top

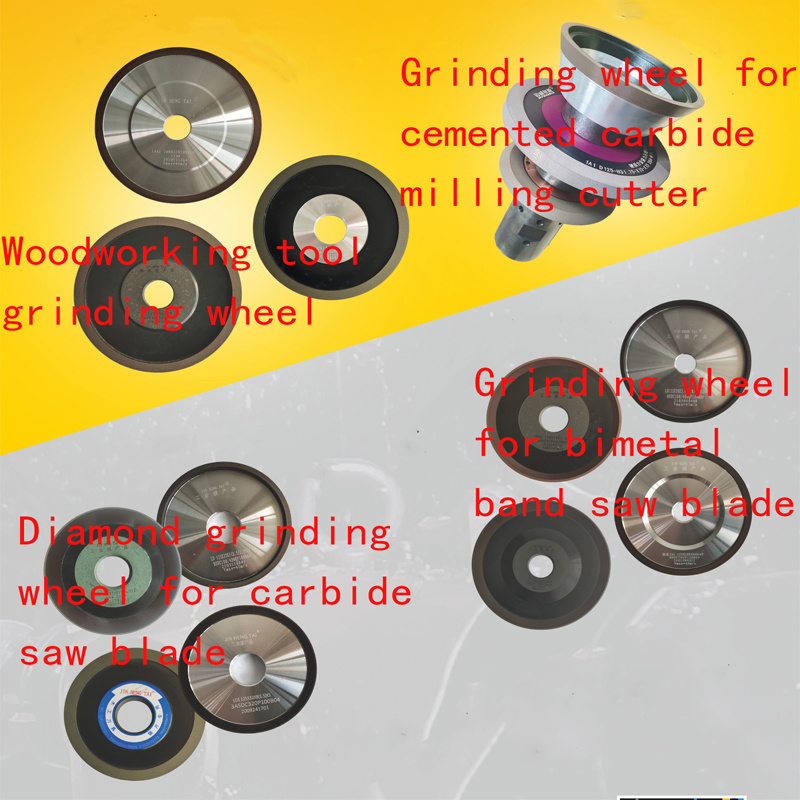

More Products

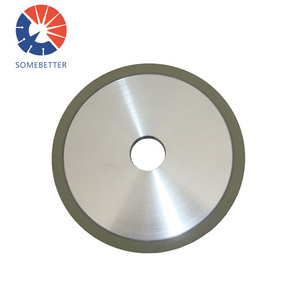

Face grinding wheel

Top grinding wheel

Side grinding wheel

Hot Searches