- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YuanDa

-

Company Style:

-

Manufacture

-

Item Name:

-

biomass burner/ biomass boiler/ hot air stove

-

Dimension:

-

According to Model

-

Color:

-

Customized

Quick Details

-

Type:

-

Biomass Burner

-

Weight (KG):

-

100

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YuanDa

-

Company Style:

-

Manufacture

-

Item Name:

-

biomass burner/ biomass boiler/ hot air stove

-

Dimension:

-

According to Model

-

Color:

-

Customized

biomass burner/ biomass boiler/ hot air stove

According to the heating form, hot air boiler can be divided into:

(1) D irect hot air boiler (without heat exchanger, directly heated by flue gas) .After fuel is burned, the flue gas is directly discharged from the rear of the combustion furnace and enters the subsequent drying equipment.

Application: This type of hot air boiler is mainly used for drying products that do not require high cleanliness of hot air, such as cement, sand, briquette, sludge, etc.

(2) I ndirect hot air boiler (with heat exchanger, heated by clean hot air).The indirect hot air boiler uses steam, heat transfer oil, flue gas as carriers to heat the air through various forms of heat exchangers.

The most essential p art of indirect hot air stove is heat exchange. The larger the heat exchange area, the higher the heat conversion rate, the better the energy saving effect of the hot air boiler , and the longer the life of the furnace body and heat exchanger. Conversely, the size of the heat exchange area can also be identified from the flue gas temperature. The lower the smoke temperature, the higher the heat conversion rate and the larger the heat exchange area.

Application: The indirect hot air stove is mainly suitable for drying materials that are not allowed to be contaminated, or for drying heat-sensitive materials with low temperature. Such as: milk powder, pharmaceuticals, synthetic resins, fine chemicals, etc.

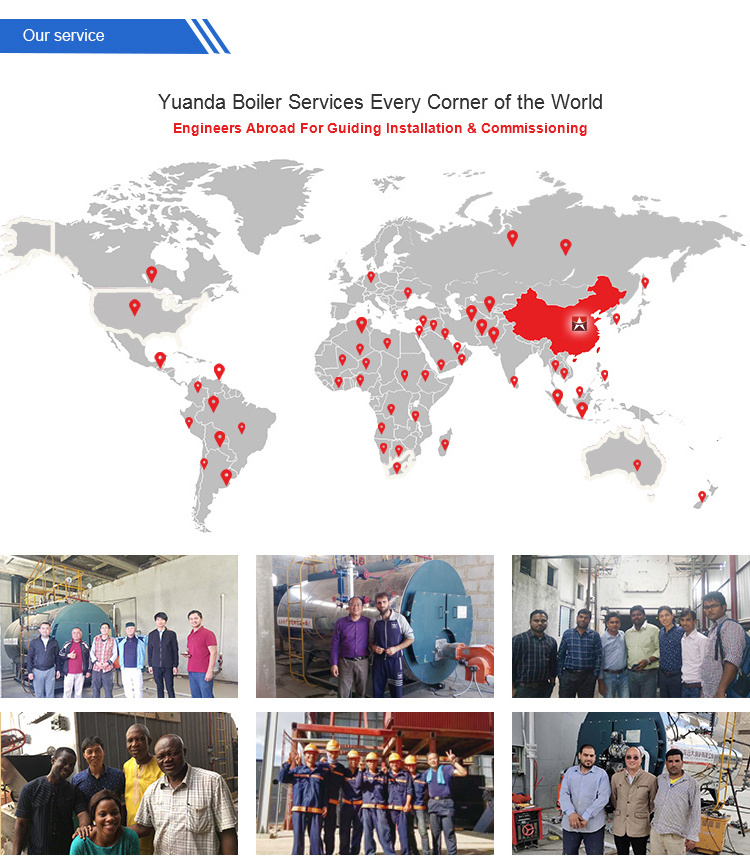

Pre-sale service:

We help customer choose the best boiler model according to different requirements of various industry. Before delivery we will provide foundation drawing, layout drawing, boiler room layout, etc.

In-sale service:

We keep 24 hours online and keep close contacts during the production process to ensure on time delivery with perfect finished product.

After-sale service:

1.provide full range of original spare parts.

2.Engineers abroad installation and commissioning service is available.

3.Our engineers will held a training for boiler workers to ensure the safe operation.

4.Free maintenance and repair for one year and lifelong service.