- Product Details

- {{item.text}}

Quick Details

-

Suit for:

-

Potato / carrot / pumpkin / taro

-

Production:

-

150-220KG/H

-

Barrel diameter:

-

380mm / 290mm

-

frequency:

-

50HZ

-

After service:

-

free spare parts

-

work life:

-

6-8years

-

Advantage:

-

easy to control

-

Packing:

-

wooden case

-

Color:

-

Silver

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

Shandong, China

-

After-sales Service Provided:

-

Free spare parts

-

Material:

-

Stainless Steel

-

Suit for:

-

Potato / carrot / pumpkin / taro

-

Production:

-

150-220KG/H

-

Barrel diameter:

-

380mm / 290mm

-

frequency:

-

50HZ

-

After service:

-

free spare parts

-

work life:

-

6-8years

-

Advantage:

-

easy to control

-

Packing:

-

wooden case

-

Color:

-

Silver

-

Certification:

-

CE ISO

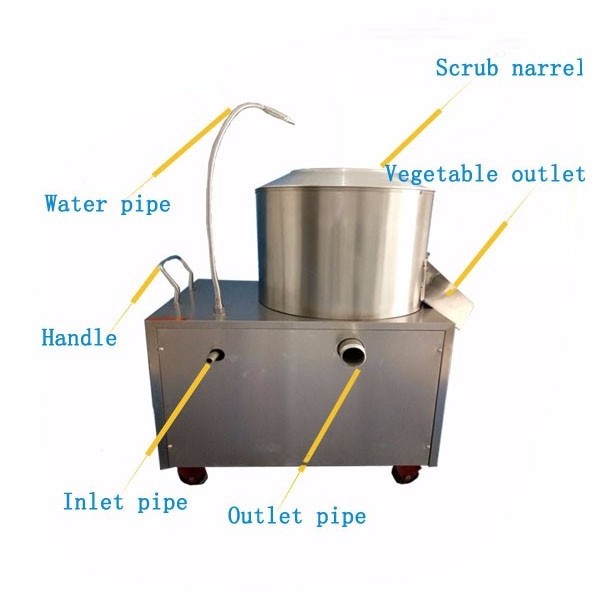

The commercial potato peeler and slicer machine/industrial potato peeler and slicer machine / small scale potato peeling machine

Introduction of Potato Peeling machine

potato peeling machine uses the centrifugal rotation, friction peeling technology, potato, taro, water chestnuts and other vegetables peeling and cleaning. The utility model has the advantages of reasonable structure, firmness, durability, simple and convenient operation, and is very suitable for the use of food processing plants in restaurants, schools, hotels and enterprises. The utility model has the advantages of peeling, cleanness, sanitation, low breaking rate, high production efficiency and simple and convenient operation.

Totato peeling machine Operation Method

1. Turn on the power, start the switch, (such as equipped with three-phase motor, need to see whether the direction of rotation of the tube within the cylinder is marked with the rotating direction of the arrow on the cylinder, the inconsistency will be three-phase power of any two Phase transfer can be re-connected) with a hose to the water inlet and tap water switch connected to the sewage discharge can be connected according to the situation hose, put the container or directly row sewer.

2. Before potato peeling machine, the potatoes from the mouth into the 350 each time / 10-15 kg is appropriate, 450 each 20-30 kg is appropriate.

3. Open the water switch, flush into the cylinder, the amount of metal inlet pipe to adjust the amount of water, start the machine switch.

4. Potato peeling Machine work about 2 minutes or so, turn off the power switch and the water switch, depending on the potato peeling situation, if the potato skin has been off the net, you can open the cylinder door, start the power switch, potatoes in the dial plate rotation driven, Automatic removal.

5. During the use of the potato peeling machine, if any abnormal conditions (such as the body into the hard body), should quickly turn off the power switch, to be troubleshooting, restart, the machine work properly.

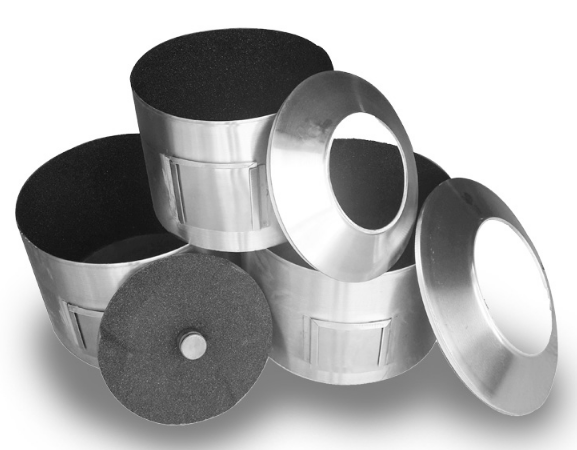

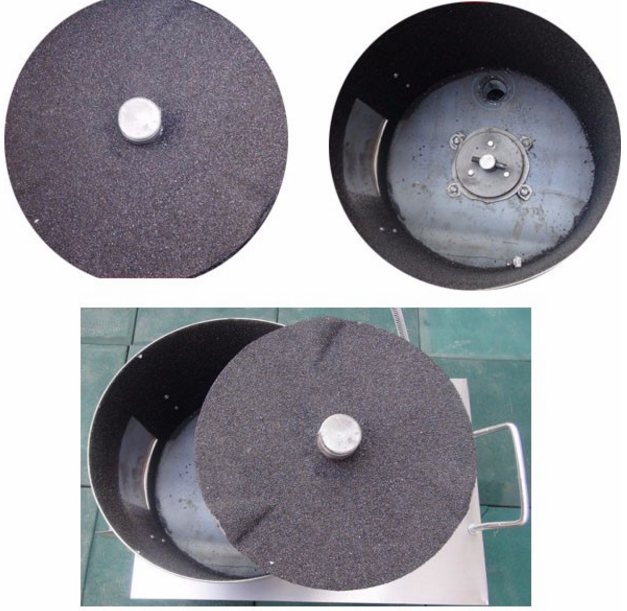

Sand table

Fine emery

Reinforced wheel

Easy to move,

save time and energy

Water flow

potato peeling machine working principle

When the potatoes into the machine barrel, rotating dial tray and peeled potatoes and potatoes up due to friction, collision and friction potatoes does not stop in the cylinder wall, to peel the potatoes with higher efficiency, at the same time with the flush pipe grinding under the skin clean and wash the dirt through a drainage hole with water.

-------Potato peeling machine-----

Inlet pipe

outlet pipe

Professional design, simple and practical waterproof impermeableProfessional design, simple and practical waterproof impermeable

Tighten nut

High quality material

Powerful motor

Manual cutting

A wast of time and manpower with the low efficiency :

Potato peeling Machine cutting :

All full automated , fast processing time, saves the manpower, the clean health and high efficiency

Generally,we adopt standard containers, bare main machine, motors and small parts are packed in wooden cases.Or depend on your demands.

1.The mode of transportation we according to the size of the goods or the customer requirements, the samll package will take the DHL , TNT, UPS ect , the large size package machine will take the sea shipping and 20ft, 40ft, 40hp container

2. Waterproof packing with the international export standard by 20ft, 40ft, 40hp container. Equipment Fittings, Electric Motor and Power Cabinet will be packed in Wooden Case or Iron Box. Other Equipment will be packed by Color-Stripes Plastic Cloth.

3.The whole plant machinery size are large as normal, so we will use Waterproof cloth to pack all of them. The motor, gear box or other easily damaged parts, we will put them into box. We have a professional shipping department, they will try them best to save your container quantity.