- Product Details

- {{item.text}}

Quick Details

-

Power:

-

120KW

-

Dimension(L*W*H):

-

10000*2500*2800mm

-

Weight:

-

3500kg

-

Production Capacity:

-

500-600KG/24Hours

-

Product name:

-

meltblown fabric production line

-

Application:

-

Making Disposable Face Mask

-

Final products:

-

meltblown fabric

-

Keywords:

-

meltblown fabric

-

Machine Type:

-

extrusion machine

-

Model:

-

SJ65/30

-

Motor:

-

Siemens

-

Inverter:

-

ABB

-

Temperature control meter:

-

Omron

-

Contacts:

-

Schneider

-

Certification:

-

ISO/ CE

Quick Details

-

Voltage:

-

380V/220V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Lianshun

-

Power:

-

120KW

-

Dimension(L*W*H):

-

10000*2500*2800mm

-

Weight:

-

3500kg

-

Production Capacity:

-

500-600KG/24Hours

-

Product name:

-

meltblown fabric production line

-

Application:

-

Making Disposable Face Mask

-

Final products:

-

meltblown fabric

-

Keywords:

-

meltblown fabric

-

Machine Type:

-

extrusion machine

-

Model:

-

SJ65/30

-

Motor:

-

Siemens

-

Inverter:

-

ABB

-

Temperature control meter:

-

Omron

-

Contacts:

-

Schneider

-

Certification:

-

ISO/ CE

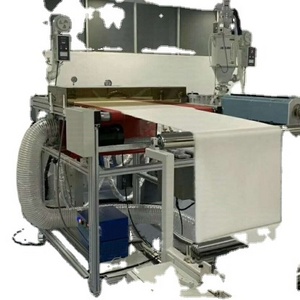

PP Mask Meltblown Fabric Making Machine

Description:

Mask Meltblown fabric mainly consists of polypropylene, polyurethane and polylactic acid, and the fiber diameter can reach 1-5microns. It has good fiterability, shielding, thermal insulaton and oil absorption. It can be applied to medical and sanitary cloths, such as surgical gowns, protective clothing, disinfection cloths, masks, diapers, sanitary napkins for women, etc. It has outstanding performance in industry and can be used as filter materials, insulating materials, cement packaging bags, geotextiles, wrapping cloths,etc.

How is mask meltblown fabric being produced?

The meltblown fabric production equipment is meltblown machine or meltblown fabric production line equipment. The meltblown fabric production line consists of the following parts:

Screw extruder: melt the slices

Metering pump: control the output and fiber fineness to continuously deliver melt to spinneret.

Melt filter: filters imprurities in the melt.

Conveying net curtain: melt blown fibers are evenly received and spread on the net.

Spinning box: immediately after the fibers are injected, high speed hot air is used for airflow stretching to break the fibers into superfine fibers.

Feeding system: consists of 3 measuring hoppers, which are used to measure white slices, color masterbatch and additives respectively.

Hot air blower and heater: provide the temperature and pressure of hot air used in spinning air flow drawing, which is electrically heated and consumes a large amount of electricity.

Colier: full-automatic coiling is adopted to package meltblown cloth into rolls.

Detailed Pictures:

Test Report:

Certificates:

Packing & Shipping:

Exhibitions show:

If you are interested in PP meltblown fabric making machine, welcome to inquiry!