- Product Details

- {{item.text}}

Quick Details

-

Cutting Area:

-

900*600mm

-

Cutting Thickness:

-

Materials

-

Control Software:

-

RDCAM

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Voiern

-

Weight (KG):

-

150 KG

-

After-sales Service Provided:

-

online support, Online support, Video technical support

-

Product name:

-

C02 Laser Engraving Cutting Machine

-

Laser tube:

-

CO2 Laser Tube

-

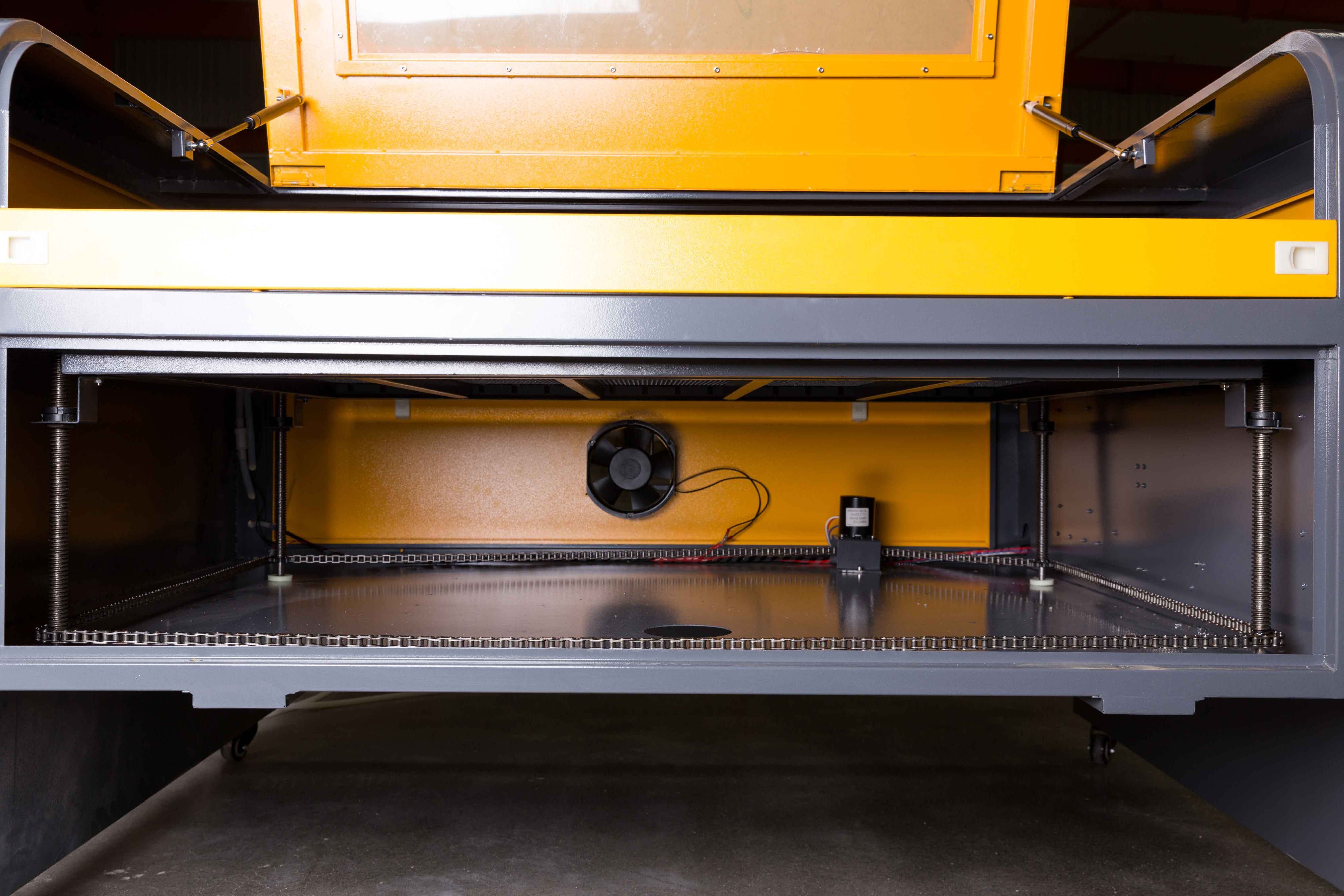

Color:

-

Yellow

-

Laser power:

-

60w/80w/100w/130w/150w

-

Cutting materials:

-

non-metal materials

-

Driving system:

-

Stepper Motor

-

Working table:

-

Honeycomb Table

-

Control system:

-

Ruida Control System

-

Laser source:

-

Co2 Laser Source

Quick Details

-

Laser Type:

-

CO2

-

Cutting Speed:

-

0-800mm/s

-

Cooling Mode:

-

WATER COOLING

-

Cutting Area:

-

900*600mm

-

Cutting Thickness:

-

Materials

-

Control Software:

-

RDCAM

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Voiern

-

Weight (KG):

-

150 KG

-

After-sales Service Provided:

-

online support, Online support, Video technical support

-

Product name:

-

C02 Laser Engraving Cutting Machine

-

Laser tube:

-

CO2 Laser Tube

-

Color:

-

Yellow

-

Laser power:

-

60w/80w/100w/130w/150w

-

Cutting materials:

-

non-metal materials

-

Driving system:

-

Stepper Motor

-

Working table:

-

Honeycomb Table

-

Control system:

-

Ruida Control System

-

Laser source:

-

Co2 Laser Source

Product Description

Our products can be selected according to the customer's work needs.

Advantages of CO 2 laser engraving:

1. Wide range: carbon dioxide laser can carve and cut almost any non-metallic material. And the price is low!

2. Safe and reliable: non-contact processing will not cause mechanical extrusion or mechanical stress to materials. No "knife mark", no damage to the surface of the workpiece; no deformation of the material;

3. Precision and delicacy: the machining accuracy can reach 0.02mm;

4. Saving environmental protection: the diameter of light beam and spot is small, generally less than 0.5mm; cutting and

processing saves materials, safety and health;

5. Consistent effect: ensure that the processing effect of the same batch is completely consistent.

6. High speed and fast: high speed carving and cutting can be carried out immediately according to the drawings output by the computer.

7. Low cost: not limited by the processing quantity, laser processing is cheaper for small batch processing services.

1. Wide range: carbon dioxide laser can carve and cut almost any non-metallic material. And the price is low!

2. Safe and reliable: non-contact processing will not cause mechanical extrusion or mechanical stress to materials. No "knife mark", no damage to the surface of the workpiece; no deformation of the material;

3. Precision and delicacy: the machining accuracy can reach 0.02mm;

4. Saving environmental protection: the diameter of light beam and spot is small, generally less than 0.5mm; cutting and

processing saves materials, safety and health;

5. Consistent effect: ensure that the processing effect of the same batch is completely consistent.

6. High speed and fast: high speed carving and cutting can be carried out immediately according to the drawings output by the computer.

7. Low cost: not limited by the processing quantity, laser processing is cheaper for small batch processing services.

Hot Searches