- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

3000*1500

-

Cutting Thickness:

-

1-30

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Qiaolian

-

Weight (KG):

-

15500 KG

-

Product name:

-

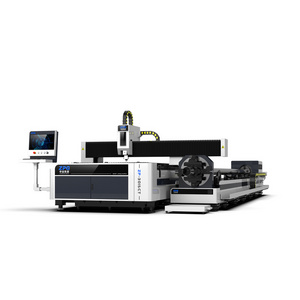

loading and unloading system for fiber laser cutting machine

-

Laser source:

-

MAX IPG RAYCUS

-

Software:

-

AutoCAD

-

Certification:

-

ce, ISO, Sgs

-

After-sales Service Provided:

-

Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Malaysia, Australia, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Romania, South Africa, Ukraine, Kyrgyzstan, Uzbekistan, Tajikistan

-

Showroom Location:

-

Egypt, Canada, Turkey, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, India, Mexico, Russia, Thailand, South Korea, Chile, UAE, Bangladesh, South Africa, Uzbekistan, Australia

-

Marketing Type:

-

Hot Product 2020

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

120m/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

3000*1500

-

Cutting Thickness:

-

1-30

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Qiaolian

-

Weight (KG):

-

15500 KG

-

Product name:

-

loading and unloading system for fiber laser cutting machine

-

Laser source:

-

MAX IPG RAYCUS

-

Software:

-

AutoCAD

-

Certification:

-

ce, ISO, Sgs

-

After-sales Service Provided:

-

Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Malaysia, Australia, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Romania, South Africa, Ukraine, Kyrgyzstan, Uzbekistan, Tajikistan

-

Showroom Location:

-

Egypt, Canada, Turkey, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, India, Mexico, Russia, Thailand, South Korea, Chile, UAE, Bangladesh, South Africa, Uzbekistan, Australia

-

Marketing Type:

-

Hot Product 2020

Sample

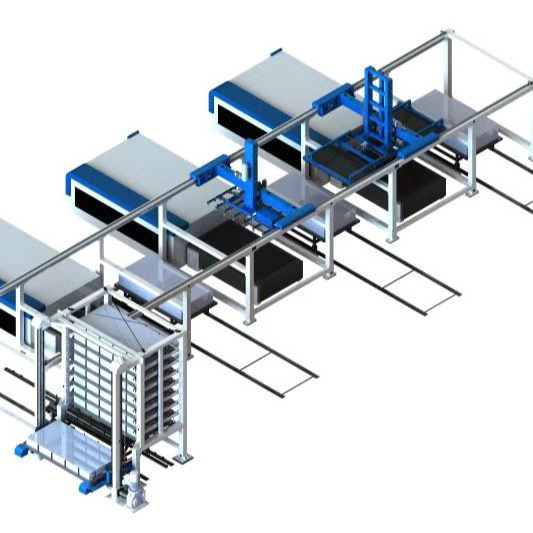

Cantilever type automatic loading system

Parameter

|

1

|

Model

|

17SXL150

|

|

2

|

Rated load (Have separate material system)

|

150kg

|

|

3

|

Maximum workpiece size when loading

|

3000×1500

|

|

4

|

Maximum thickness of workpiece when loading

|

4--7

|

|

5

|

Machine size

|

5800×1850X2700

|

|

6

|

Total weight

|

1700kg

|

|

7

|

Slewing arm radius of gyration

|

3150

|

|

8

|

Minimum resolution of rotation

|

0.1mm

|

|

9

|

Rotation angle

|

120--180 degrees

|

|

10

|

Rotary arm lifting height

|

850mm

|

|

11

|

Repeat positioning accuracy

|

±1mm

|

|

12

|

Lifting minimum resolution

|

0.1mm

|

|

13

|

Lifting speed

|

3m/min

|

|

14

|

Repeat positioning accuracy

|

±1mm

|

|

15

|

Minimum size of loading workpiece

|

1000×1000

|

|

16

|

Minimum workpiece size of separated material

|

150x150x4

|

|

17

|

Lifting motor power

|

3KW

|

|

18

|

Swing motor

|

0.55KW

|

|

19

|

Vacuum system working pressure

|

-40~-80KPa

|

|

20

|

Working power supply

|

AC380 5KW

|

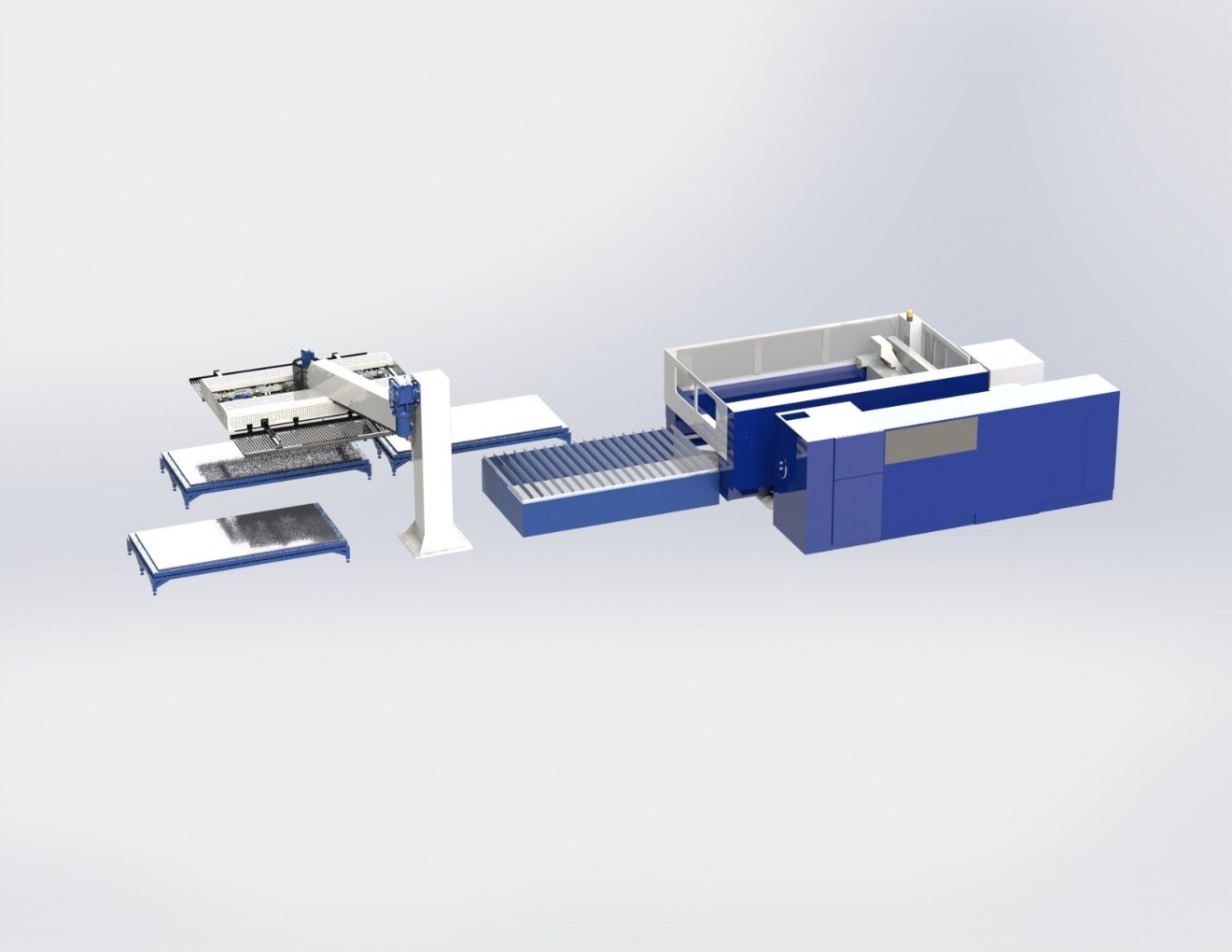

Schematic Diagram

Wuxi Cylion Technologu Co.,Ltd

Wuxi Cylion Technologu Co., Ltd is a branch of Qiaolian group,responsible for R&D advanced industrial technologu for Qiaolian group long-term growth,and promoting CNC equipment and parts produced bu Qiaolian group companies on oversea market.

Qiaolian group companies are engaged in steel production line,steel fabrication equipments like CNC machining centre,lathe,Plasma,laser cutting&welding machines,CNC control systems and parts design,production and service.

Welcome to visit our factories in Wuxi,Changzhou

1. Why your machine price is higher, we have much cheaper offer from Jinan factories?

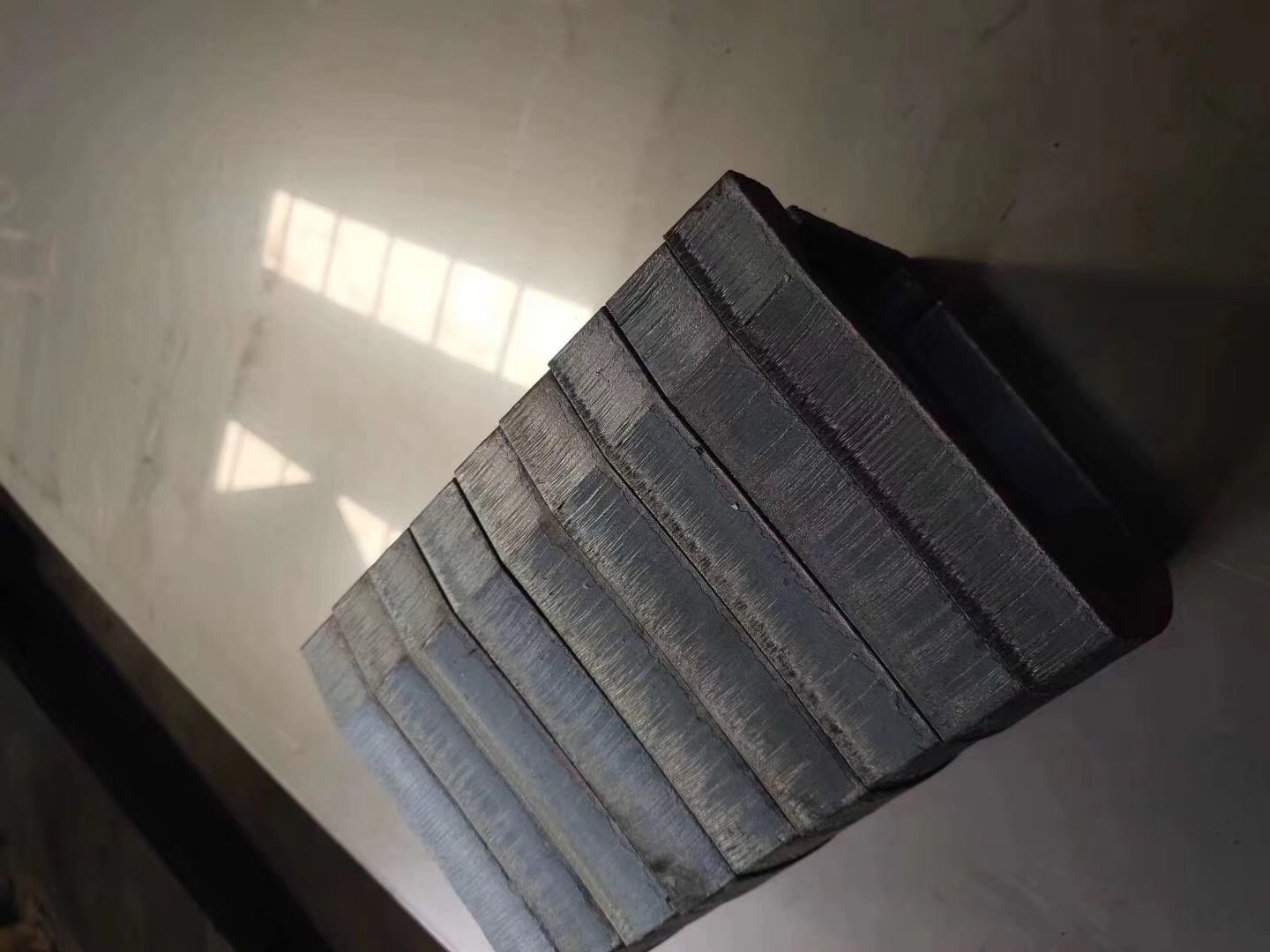

Qiaolian machine feature is robust table design like Europen brand machine with complete plate-welded structure, and heaviest in China.

You will check it out by real shipping weight!

We always try to make high level machines that few factories can copy, because we have experienced engineers which are limited source in this field.

So if you don’t have much cutting work, our machine is not cost-effective to you.

2.Can you produce the machine faster ?

As we need the machine urgently, High level machine is not simply assemble parts together and deliver it to customer. We don’t do fast production. Long-termmachine stability depends on strict quality control. Inspection and testing work needs enough time if you wish to get long-time stable work machine.

We mainly rely on old customers recommend our machines to others to expand business. The machines we produced are best advertisement for us.

3. Why not offer 3 years warranty as Jinan factory?

Warranty service costs money if the supplier really do free service. We don’t understand how can a company offer cheaper price and longer warranty at same time, unless the supplier just talk about it and play words game. because international parts delivery,air ticket…. not cheap at all, we do spend much money on service after sales, we seriously do as we said, you can check it with any of our old customer.

Without additional charge, we can not fulfil the responsibility of additional warranty.

4. How to choose laser power?

We suggest to choose laser power according to your main cutting thickness, no need to choose a bigger power for a max cutting thickness less than 10% of total work. As far as we see,customer’s business always grows after using laser cutting machine, and need second or third machine along with business expand.

You don’t need to make a big investment from the start.

High quality cutting is different from max thickness cutting, you need to consider quality request,too.

Hot Searches