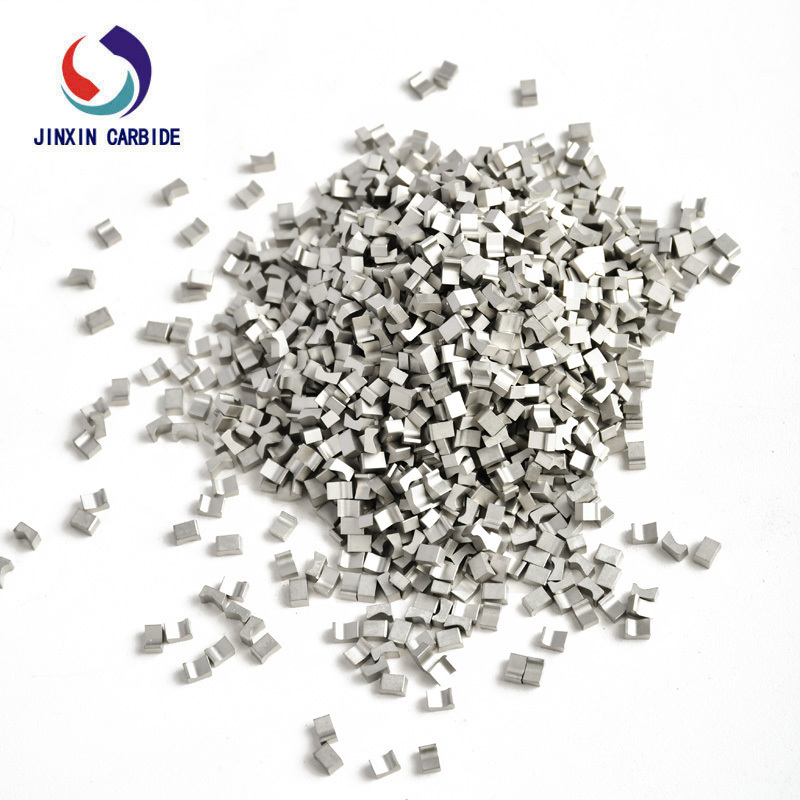

- Product Details

- {{item.text}}

Quick Details

-

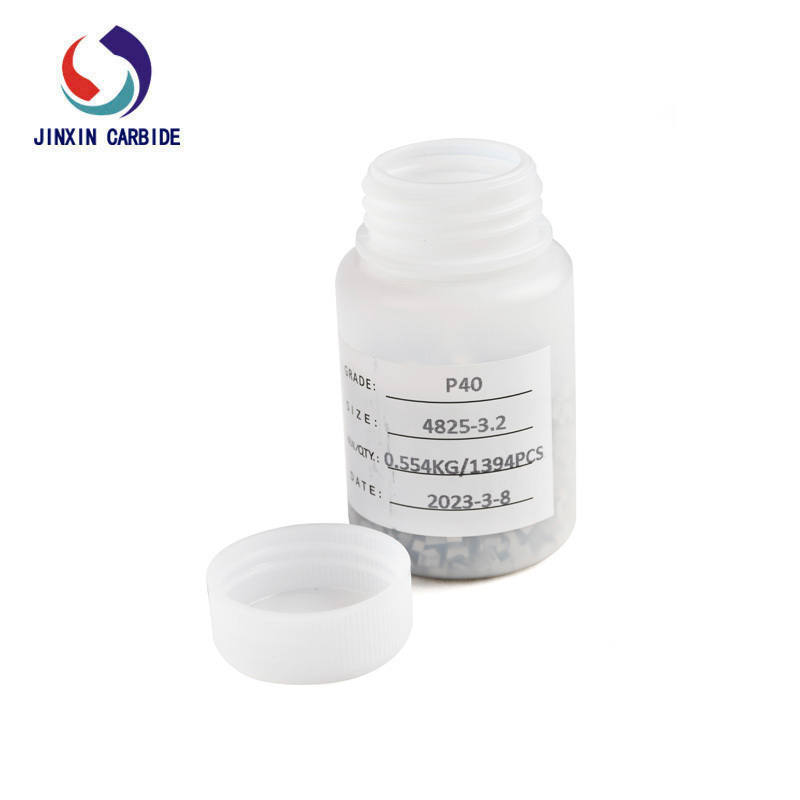

Model Number:

-

carbide saw tips

-

Product name:

-

K20 Cemented Carbide Circular Blades Saw Tips for Cutting Wood

-

Material:

-

Tungsten carbide

-

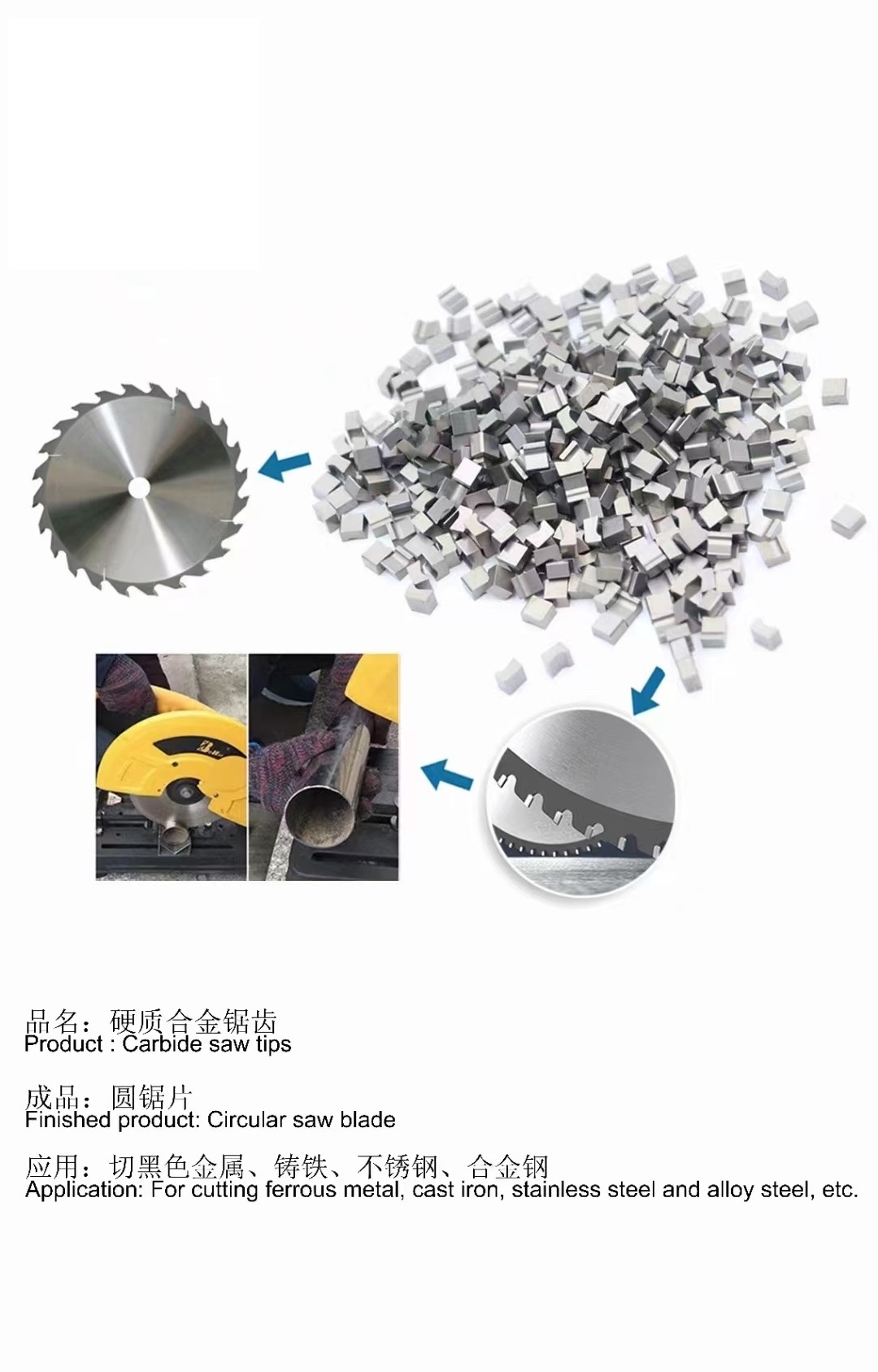

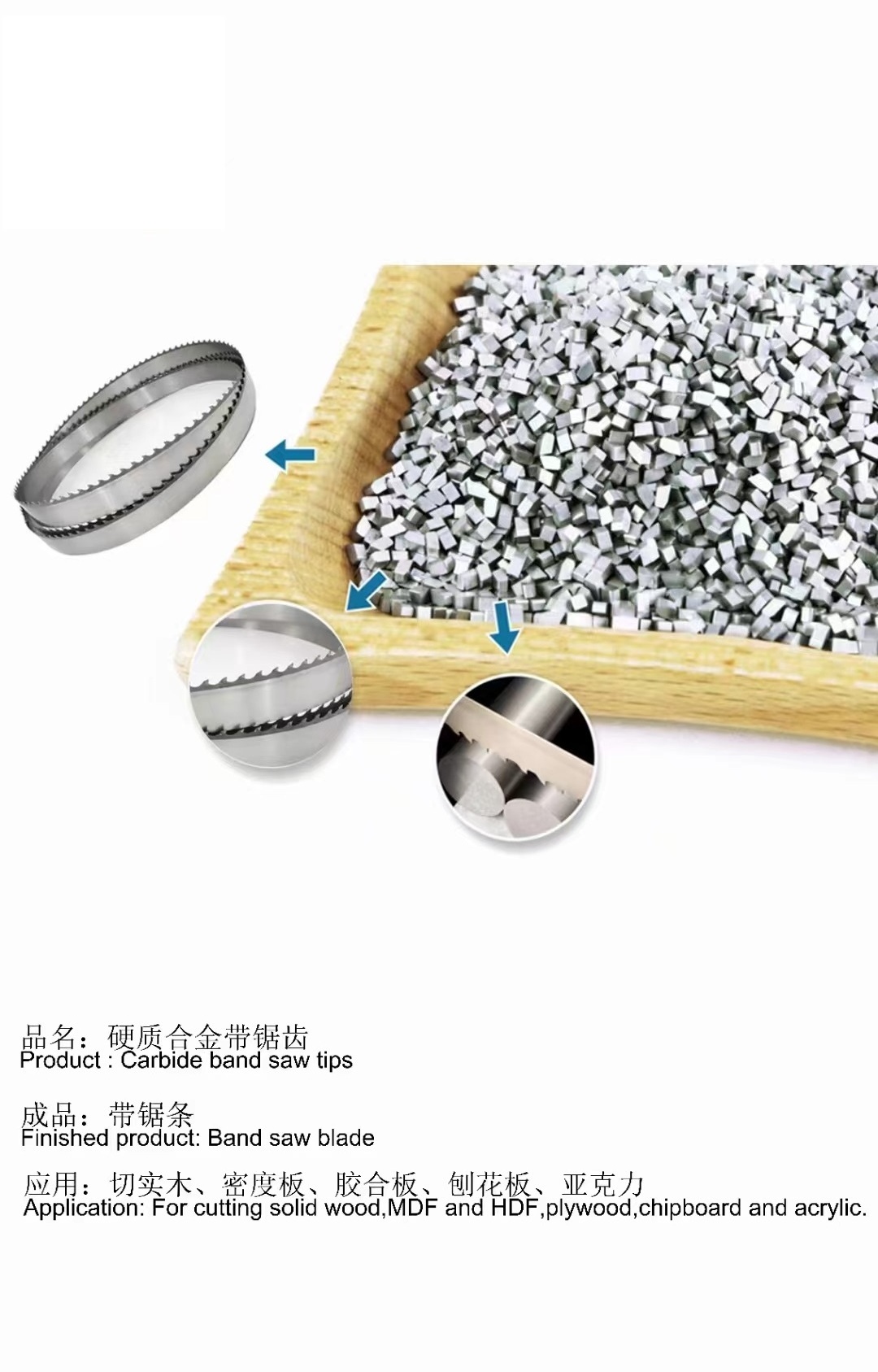

application:

-

for saw blade

-

MOQ:

-

3kgs

-

Model:

-

Different Size

-

Tool type:

-

Brazed

-

Feature:

-

high hardness, wear resistance

-

Advantage:

-

long life

-

Keywords:

-

tungsten carbide saw tips

-

Certifications:

-

ISO9001:2015

Quick Details

-

Warranty:

-

3 months

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

Jinxin

-

Model Number:

-

carbide saw tips

-

Product name:

-

K20 Cemented Carbide Circular Blades Saw Tips for Cutting Wood

-

Material:

-

Tungsten carbide

-

application:

-

for saw blade

-

MOQ:

-

3kgs

-

Model:

-

Different Size

-

Tool type:

-

Brazed

-

Feature:

-

high hardness, wear resistance

-

Advantage:

-

long life

-

Keywords:

-

tungsten carbide saw tips

-

Certifications:

-

ISO9001:2015

Products Description

Advantage:

1. High quality & 100% virgin raw material with stable properties and long working life;

2. Dark grey surface with hot sale at Brazil, Russia and other market;

3. Precision dimensions with good unit weight and size accuracy;

4. Various sizes and types for your choice;

2. Dark grey surface with hot sale at Brazil, Russia and other market;

3. Precision dimensions with good unit weight and size accuracy;

4. Various sizes and types for your choice;

5. Longstanding old customers with over tons export amount every month.

Common Grades

|

ISO Code

|

Grade

|

Physical and Mechanical Properties

|

|

|

Recommended Applications

|

||

|

|

|

Densityg/cm3

|

Hardness

HRA(HV |

TRS

Mpa |

Recommended Applications

|

||

|

K05

|

YG3

|

15

|

90.5

|

1300

|

Suitable for finishing of cast iron and

nonferrous metal. |

||

|

K10

|

YG6X

|

14.8

|

91

|

1560

|

The finishing& semi-finishing

of cast iron and nonferrous metals and also for the machining of manganese stell and hardening steel. |

||

|

|

YG6A

|

14.7

|

91.5

|

1510

|

|

||

|

K15

|

YG6

|

14.9

|

89.5

|

1670

|

Suitable for the roughing of cast iron and light

alloys and also for the milling of cast iron and low-alloy steel. |

||

|

K20

|

YG8

|

14.6

|

89

|

1840

|

Suitable for the roughing of cast iron

and light alloys and also for the milling of cast iron and low-alloy steel. |

||

|

M10

|

YW1

|

13

|

91

|

1290

|

Suitable for finishing and semi-finishing

of stainless steel and conventional alloy steel. |

||

|

|

YW3

|

12.9

|

92

|

1390

|

|

||

|

|

YW4

|

12.3

|

92

|

1390

|

|

||

|

M20

|

YW2

|

12.9

|

90.5

|

1460

|

The grade can be used for the semi-finishing

of stainless steel and low-alloy steel and it is mainly used for the maching of railway wheel hubs. |

||

|

P10

|

YT05

|

12.6

|

92.5

|

1260

|

Suitable for the finihing and semi-finishing if

steel and cast steel with a moderate feed rate and a rather high cutting speed. |

||

|

|

YT15

|

11.3

|

91

|

1300

|

|

||

|

P20

|

YS14

|

11.4

|

91.5

|

1550

|

Suitable for the finishing and semi-finishing

of steel and cast steel. YS25 is specially used for the milling of steel and cast steel. |

||

|

|

YT14

|

11.4

|

90.5

|

1400

|

|

||

|

|

YS25

|

13

|

90.5

|

1780

|

|

||

|

M10

|

60

|

12.8

|

92.5

|

1500

|

Mainly used for threading of petroleum pipe,

also used for fine machining of hardened steel. |

||

|

M20

|

YM20

|

13

|

91

|

1750

|

Suitable for steel, cast steel, manganese steel,

grey cast iron, medium cutting speed and feed rate by half finishing and semi-finishing end mills. |

||

|

P30

|

YC30S

|

12.9

|

90

|

1600

|

Used for the milling of steel, cast steel

ans alloy steel. |

||

|

P35-P40

|

YC40

|

12.9

|

91

|

2200

|

Suitable for the heavy duty turning of steel and

cast steel with a big steel rate under unfavorable working condifion. |

||

|

P40

|

YM40

|

12.75

|

90

|

2100

|

Suitable for the heavy duty turning of steel and

cast steel with a big steel with a big steel rate and also for face milling. |

||

|

|

YC45

|

12.75

|

90

|

2300

|

|

||

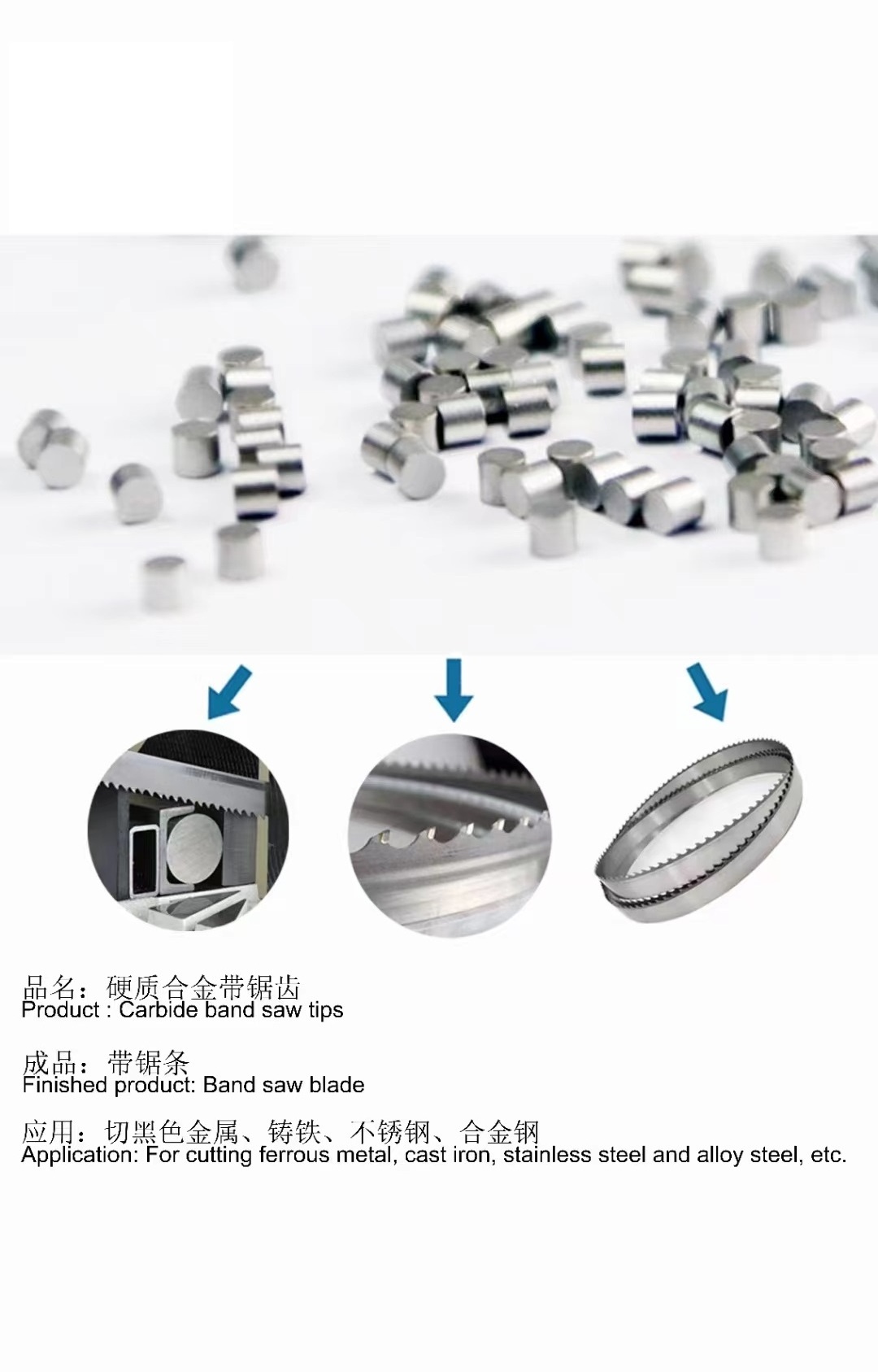

Application scenarios

Product Show

Main Products

Q1. Are you manufacturer or trading company ?

A: We are manufacturer of tungsten carbide products.

Q2. Is the price Competitive?

A: Jinxin offer reliable products with good price.

Q3. Are the products High Quality?

A: Yes. Raw material will be tested before bulk production, and we will check the physical properties, shape and tolerance for

ensuring qualified products before shipping.

Q4. How to place an order of tungsten carbide products?A:1. Fill your Order List in our online Inquiry System.

(Also you can directly contact our sales person by E-mail / Skype / Whats App)

2. within 24-hours feedback when receiving your message.

Q5: How we can trust your company ?

A:We support Alibaba trade insurance , 100% products quality protection, 100% on-time shipment protection, 100% payment protection

for your covered amount.

Q6: What’s your delivery time ?

A:For the normal type which we have mold it takes two weeks after receiving the

advance payment.

For the non standard which we do not have mold it takes 4 to 6 weeks when receiving the advance payment.

A: We are manufacturer of tungsten carbide products.

Q2. Is the price Competitive?

A: Jinxin offer reliable products with good price.

Q3. Are the products High Quality?

A: Yes. Raw material will be tested before bulk production, and we will check the physical properties, shape and tolerance for

ensuring qualified products before shipping.

Q4. How to place an order of tungsten carbide products?A:1. Fill your Order List in our online Inquiry System.

(Also you can directly contact our sales person by E-mail / Skype / Whats App)

2. within 24-hours feedback when receiving your message.

Q5: How we can trust your company ?

A:We support Alibaba trade insurance , 100% products quality protection, 100% on-time shipment protection, 100% payment protection

for your covered amount.

Q6: What’s your delivery time ?

A:For the normal type which we have mold it takes two weeks after receiving the

advance payment.

For the non standard which we do not have mold it takes 4 to 6 weeks when receiving the advance payment.

Hot Searches