- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Ailin

-

Voltage:

-

380V/220V/110V, or customized

-

Dimension(L*W*H):

-

Customized Design

-

Weight (KG):

-

10000

-

Production line type:

-

Powder coating/Painting

-

Curing Temperature:

-

180-220 degrees, adjustable

-

Chain Length:

-

Based on required output

-

Powder Recovery:

-

High recovery rate, quick color change

-

After-sales Service:

-

Engineers available to service overseas

Quick Details

-

Machine Type:

-

Automatic powder coating line, Spray Booths, Spray Booths, Painting Equipment, Pre-treatment Equipment, Conveying Equipment, Coating Equipment, Other

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Ailin

-

Voltage:

-

380V/220V/110V, or customized

-

Dimension(L*W*H):

-

Customized Design

-

Weight (KG):

-

10000

-

Production line type:

-

Powder coating/Painting

-

Curing Temperature:

-

180-220 degrees, adjustable

-

Chain Length:

-

Based on required output

-

Powder Recovery:

-

High recovery rate, quick color change

-

After-sales Service:

-

Engineers available to service overseas

PRODUCT DESCRIPTION

AILIN

Custom Automatic Powder Coating Line

The craft showed in line with “econom

y

, science, practical, reliable, energy conservation” the principle.

In order to

▶

Enhance the appearance coating quality of products.

▶

Improve worker's operating environment thoroughly.

▶

Reduce worker's labor intensity and

energy consumption

.

▶

S

moothen

the physical distribution.

▶

The labor productivity will be higher.

|

Model:

|

AL-T313

|

|

|

Main Material:

|

Steel, PP

|

|

|

Work Dimensions (L×W×H):

|

According to engineer's design, based on the output required

|

|

|

Voltage/Frequency:

|

415V/380V/220V/110V as local (50-60Hz)

|

|

|

Heating Method:

|

Electric/Gas/Diesel oil/LPG

|

|

|

Wor

k Tempera

ture:

|

180°C-220°C (< ± 3-5°C), Warm-up in 15-30min

|

|

|

Operating mode

of conv

eyor:

|

Automatic (Chain speed's adjustable)

|

|

|

Powder spraying mode:

|

Manual/Automatic+Manual

|

|

|

Powder recovery(optional):

|

Primary recovery filter+Secondary filter/multi-cyclone/big cyclone

|

|

|

We can offer the design drawing and customize any size for powder coating line.

|

|

|

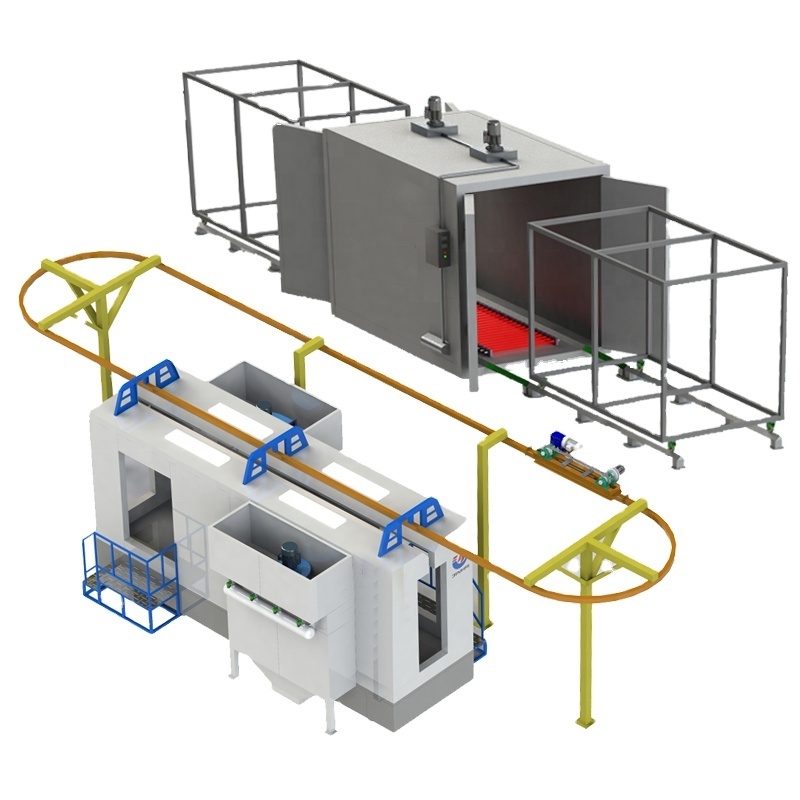

CASE STORIES

Ailin I

ntelligent

specializes in optimizing various types of project in the business of industrial surface treatment lines. We have a great deal of experience in coating line system for nearly 13+ years, and provide technical support as well as installation guide to customers. The pictures above show the cases of practical application in workshops FYI.

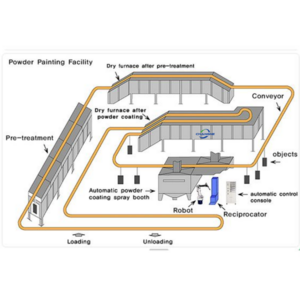

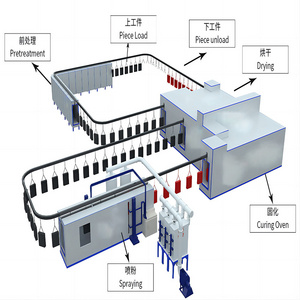

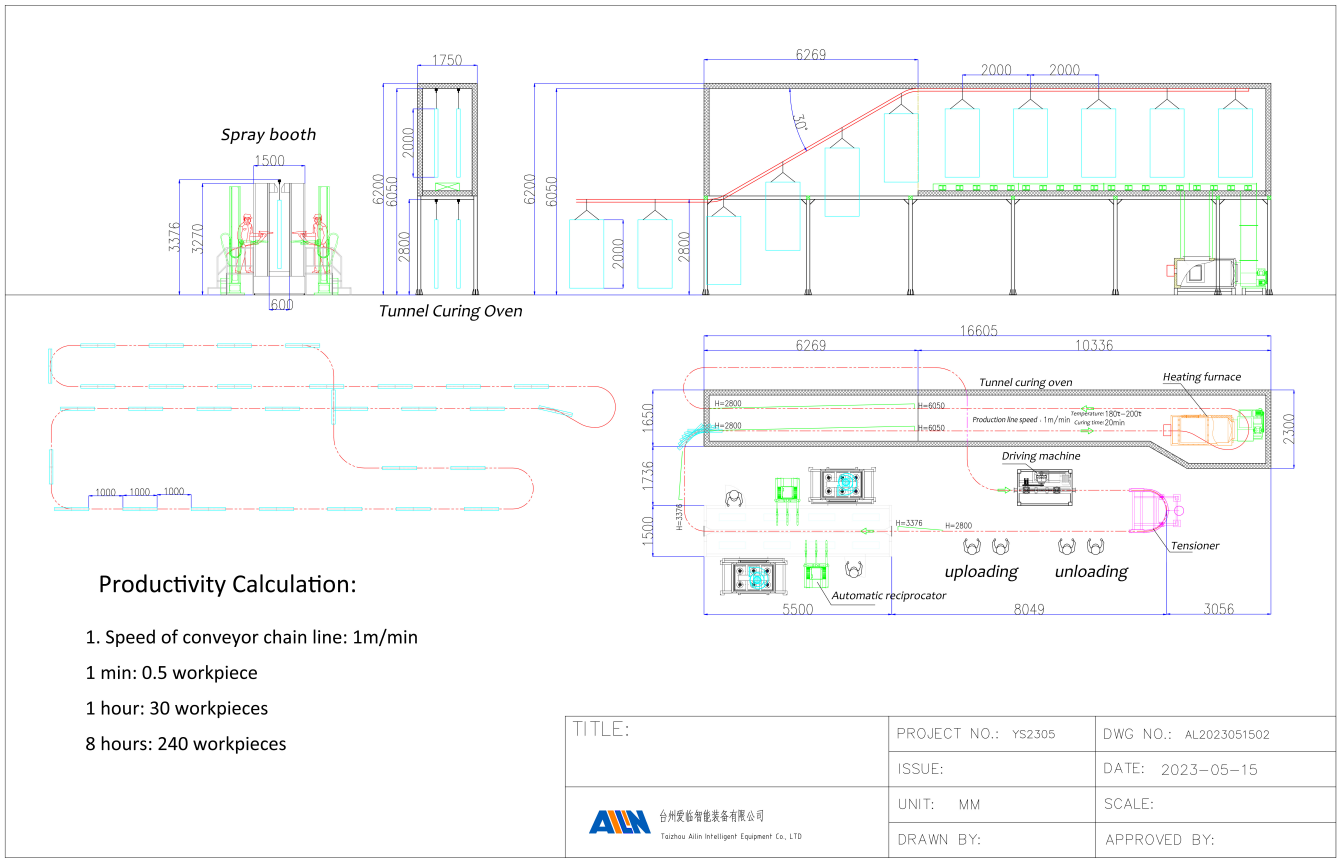

SCHEMATIC DRAWING

PROCESSES:

product loading → powder coating → curing in oven → cooling down → product unloading

COMPONENT DETAILS

Our powder coating line system includes:

Chain conveyor system, Powder coating booth, Powder filter system, Powder cyclone system, Powder coating oven.

Powder Spray Booth System:

Includes: Spray Booth + Reciprocator + Automatic Powder Coating Gun System + Powder Feed Center

<

ADVANTAGES

>

• No dust spillover, reduce powder waste.

• Quick color change.

• Easy to clean, save labor time.

• Reliable operation and durability.

• Beautiful appearance, fine workmanship.

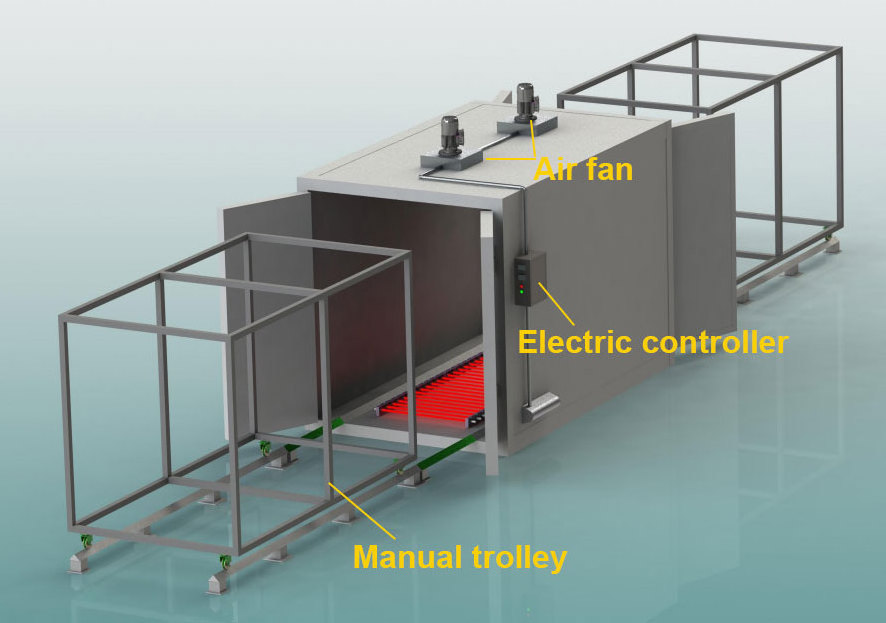

Bridge Type Curing Oven:

Made of 120mm rock wool board with galvanized steel wall, features durable and heat

-resistent.

<

ADVANTAGES

>

• Powder specific design, custom sizes and configurations available.

• High quality insulated double wall design and natural gas or liquefied petroleum gas fuel.

• Made of high quality galvanized steel construction.

• Easy access to floor-standing heating systems and exhaust system standards.

• Can be used for preheating, drying, curing or multi-functional design.

Automatic Conveying Transport System:

Overhead conveyor transport with hanger. The transportation is according to the work profiles shape, some are overhead conveyor, some are vertical such as for the car filters and some other small parts.

•

Stable metal support frame.

• Emergency stop device.

• Chain speed adjustable: 0-4M/min.

• Easy to assemble and disassemble.

OPERATING PROCESSES

CUSTOMIZATION SOLUTION

How to get an optimal solution for the powder coating line?

AILIN coating has a professional and efficient working team. Our professional senior engineer will find the best solution for you.

You'd better offer the specifications of your workpiece and related information to us:

1. The production process (if you're new on coating, we will give you specialized suggestions of the whole work)

2. The size of your workpieces (including the max length, width, height and weight)

3. The required capacity (how many pcs in 8 hours)

4. The available size of your factory (including the length, width and height)

5. The heating power (electricity, gas, LPG or diesel oil )

6. Automatic painting or manual painting

1. The production process (if you're new on coating, we will give you specialized suggestions of the whole work)

2. The size of your workpieces (including the max length, width, height and weight)

3. The required capacity (how many pcs in 8 hours)

4. The available size of your factory (including the length, width and height)

5. The heating power (electricity, gas, LPG or diesel oil )

6. Automatic painting or manual painting

7.

Pre-treatment process or not, if you do, automatic pretreatment, dipping pre-treatment or sand blasting.

8. How many colors do you need to change every day.

9. The local electricity conditions (_v/_phase/_hz)

Our powder coating system's design and production are all according to customer's requirement (capacity, size of workpiece, size of workshop).

8. How many colors do you need to change every day.

9. The local electricity conditions (_v/_phase/_hz)

Our powder coating system's design and production are all according to customer's requirement (capacity, size of workpiece, size of workshop).

PRODUCT CATEGOTIES

ABOUT US

FAQ

Hot Searches