- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V / 440V

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZHENHUA

-

Dimension(L*W*H):

-

11m x 2m x 1.5m

-

Weight:

-

500 KG

-

Product name:

-

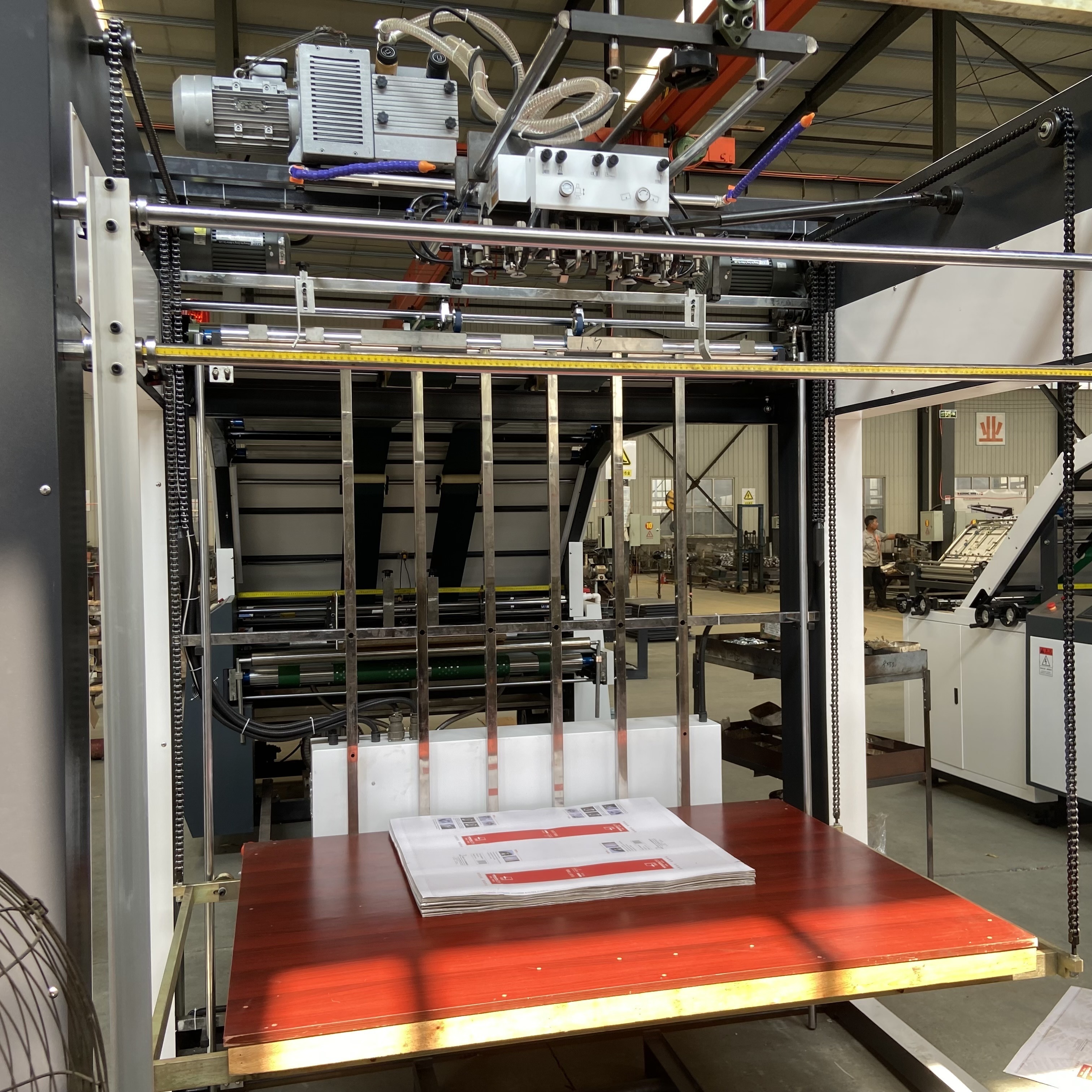

Flute laminator machine

-

Max size of cover face:

-

1600X1250mm

-

Mix size of cover face:

-

360mmX360mm

-

Economic speed:

-

100 pieceS/Min

-

Precision:

-

±1MM

-

Power:

-

11.5kw

-

Keyword:

-

Automatic laminating machine

-

Forming paperboard:

-

Less 10mm thickness paperboard

-

Base Material:

-

Flute 2 4 6 layer paperboard and 180-800gsm paper

-

Function:

-

Automatic Laminating paperboard

Quick Details

-

Packaging Type:

-

Cartons, Film

-

Packaging Material:

-

Plastic, Wood

-

Driven Type:

-

Electric

-

Voltage:

-

380V / 440V

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZHENHUA

-

Dimension(L*W*H):

-

11m x 2m x 1.5m

-

Weight:

-

500 KG

-

Product name:

-

Flute laminator machine

-

Max size of cover face:

-

1600X1250mm

-

Mix size of cover face:

-

360mmX360mm

-

Economic speed:

-

100 pieceS/Min

-

Precision:

-

±1MM

-

Power:

-

11.5kw

-

Keyword:

-

Automatic laminating machine

-

Forming paperboard:

-

Less 10mm thickness paperboard

-

Base Material:

-

Flute 2 4 6 layer paperboard and 180-800gsm paper

-

Function:

-

Automatic Laminating paperboard

Product Description

ZHENHUA QGTM Automatic Paper Processing Corrugated Lamination Machine For Pvc Fluted Panel / Paper Processing Machinery

|

Model

|

ZH-TMQG-1300A

|

ZH-TMQG-1400A

|

ZH-TMQG-1500A

|

ZH-TMQG-1600A

|

|

Max size of cover face(mm)

|

1100*1300

|

1250*1400

|

1250*1500

|

1250*1600

|

|

Mix size of cover face

(mm)

|

360*360

|

360*360

|

360*360

|

360*360

|

|

Economic speed(piece/min)

|

0-100 piece/min

|

0-100 piece/min

|

0-100 piece/min

|

0-100 piece/min

|

|

Precision

|

±1MM

|

±1MM

|

±1MM

|

±1MM

|

|

Power

|

11.5kw

|

11.5kw

|

11.5kw

|

11.5kw

|

|

Overall dimension

|

11*1.95*1.5m

|

11*2.05*1.5m

|

11*2.15*1.5m

|

11*2.25*1.5m

|

|

Weight

|

About 3.8T

|

About 3.8T

|

About 4T

|

About 4.2T

|

Introduction:

This machine adopted with motion control system and servo correction system perfect combination, using multiple sets of photoelectric sensor at the end of the paper the relative position, control top paper on both sides of the servo motor independent drive compensation action, top paper and bottom paper precise positioning. Servo laminating machine has the advantages of simple operation, only need to input the size of paper can be completed automatically adjust the machine.ervice.

This machine adopted with motion control system and servo correction system perfect combination, using multiple sets of photoelectric sensor at the end of the paper the relative position, control top paper on both sides of the servo motor independent drive compensation action, top paper and bottom paper precise positioning. Servo laminating machine has the advantages of simple operation, only need to input the size of paper can be completed automatically adjust the machine.ervice.

Major feature:

1.The vacuum suction-type feeding system can lead the paper accurately into the machine; Cycle stacking planes could stack the next batch paper well in a state of non-stop working , more efficient.

2.Bottom sheet use suction auto feeding, automatic tracking according to the face paper's speed.

3.New concept front gauge location, position high accuracy, bottom sheet never pull ahead.

4. Machine uses touch-screen/PLC/servo motor control system, circuit system is stable and could display the failure alarm automatically.

5. Automatic gluing, and the glue can be used circulatory, avoid glue waste.

6. Roller design scientifically, avoid glue fly out when the speed is high.

7. Pressure rollers adopt one side adjustment, convenient and fast.

8. Rocker controls wash roller's fluctuation, easy cleaning.

9. Counter designs scientifically, easy recording the amount you have been worked.

1.The vacuum suction-type feeding system can lead the paper accurately into the machine; Cycle stacking planes could stack the next batch paper well in a state of non-stop working , more efficient.

2.Bottom sheet use suction auto feeding, automatic tracking according to the face paper's speed.

3.New concept front gauge location, position high accuracy, bottom sheet never pull ahead.

4. Machine uses touch-screen/PLC/servo motor control system, circuit system is stable and could display the failure alarm automatically.

5. Automatic gluing, and the glue can be used circulatory, avoid glue waste.

6. Roller design scientifically, avoid glue fly out when the speed is high.

7. Pressure rollers adopt one side adjustment, convenient and fast.

8. Rocker controls wash roller's fluctuation, easy cleaning.

9. Counter designs scientifically, easy recording the amount you have been worked.

Packaging And Shipping

Certificate

Hot Searches