- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

OEM

-

name:

-

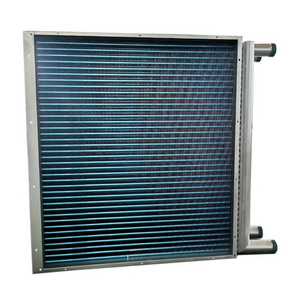

copper split air conditioner condenser

-

Tube material:

-

Copper, CuNi, Stainless steel, Aluminium, Hot dip steel, Titanium

-

Fin material:

-

Copper, Stainless steel, Aluminium, Hot deep carbon steel, Titanium

-

Tube type:

-

Smooth, Grooved

-

Fin type:

-

flat, corrugated, louvered

-

Frame material:

-

Stainless Steel, GI plate, Aluminum plate

-

Original:

-

Jiangsu, china

-

Fin surface:

-

Epoxy (gold), Blue (hydrophilic), Powder paint, Bare

-

Shape:

-

flat, L, U, G, O

-

Cooling capacity:

-

5-800kw

Quick Details

-

Type:

-

Condenser

-

Application:

-

Refrigeration Parts

-

Weight (KG):

-

50

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

OEM

-

name:

-

copper split air conditioner condenser

-

Tube material:

-

Copper, CuNi, Stainless steel, Aluminium, Hot dip steel, Titanium

-

Fin material:

-

Copper, Stainless steel, Aluminium, Hot deep carbon steel, Titanium

-

Tube type:

-

Smooth, Grooved

-

Fin type:

-

flat, corrugated, louvered

-

Frame material:

-

Stainless Steel, GI plate, Aluminum plate

-

Original:

-

Jiangsu, china

-

Fin surface:

-

Epoxy (gold), Blue (hydrophilic), Powder paint, Bare

-

Shape:

-

flat, L, U, G, O

-

Cooling capacity:

-

5-800kw

Product description

1. Product Application

·

Steam coils are a common heat source in an air handler to provide heating for many commercial and industrial buildings. The supplied air from the fans is warmed by moving across aluminum, stainless or copper fins.

The fins are warm from the exchanged heat of the steam going through the tubes. You may also see steam coils in rooftop units or ductwork.

Most steam coils we see use low pressure steam around 5 to 15 PSI.

Most steam coils we see use low pressure steam around 5 to 15 PSI.

We do sell steam coils for applications that use much higher steam pressure that are typically for process heating in a factory.

In this case it’s common to see stainless steel tubes used which can withstand the high pressures and temperatures.

2. Raw materials

|

TUBE

|

Copper

|

Titanium

|

Aluminum

|

Carbon steel

|

|

|

Stainless steel 304

|

Stainless steel 316

|

Cu-Ni(90/10)

|

Cu-Ni(70/30)

|

|

FIN

|

Copper

|

Aluminum

|

Stainless steel

|

|

|

|

Carbon steel

|

Titanium

|

|

|

|

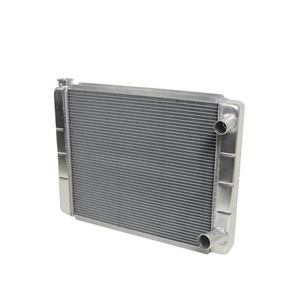

FRAME

|

Galvanized

|

Aluminum

|

Stainless steel

|

|

Details of materials

TUBES

We make tubes of different diameters, with a greater number of thicknesses and different materials such as copper, stainless steel and cupronickel. The tube expansion, during the flaring phase, allows a perfect contact between the tubes and the fins and as a consequence it assures efficient thermal exchange.

COPPER - Copper tube

STAINLESS STEEL - AISI 316L tube

CURRONICKEL - CuNi10Fe1Mn tube

FINS

The fins, made of aluminium, prevarnished aluminium or copper, are pressed by means of a particular ondulation that increases the thermal exchange between the air and the fin reducing the load losses on the air side and encouraging at the same time the flow of condensation or defrosting water.

The fins can also be made from 316L stainless steel for installations where the thermal exchange is in aggressive environments such as the food sector or exchangers used in salty environments.

The main geometries, achievable according to the chosen material, are reported following below; besides, according to the application chosen by the customer and to the thickness of the requested strap, it will be possible to make a major or minor pitch between the fins.

ALUMINIUM FINS

HYDROPHYLIC ALUMINIUM FINS

PREVARNISHED ALUMINIUM FINS

STEEL FINS 316L

COPPER FINS

PLATES

Thanks to its accurate three-dimensional design and to modern punchers and numerical control bending machines, it is possible to make carpentry and structures of different sizes that can be adapted to any construction requirement of the customer.

GALVANIZED STEEL PLATES

ALLUMINIUM PLATES

COPPER PLATES

BRASS PLATES

STAINLESS STEEL PLATES Aisi 304

plated with protective pvc

Engineering Data

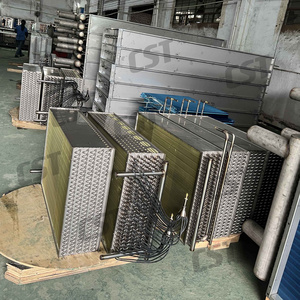

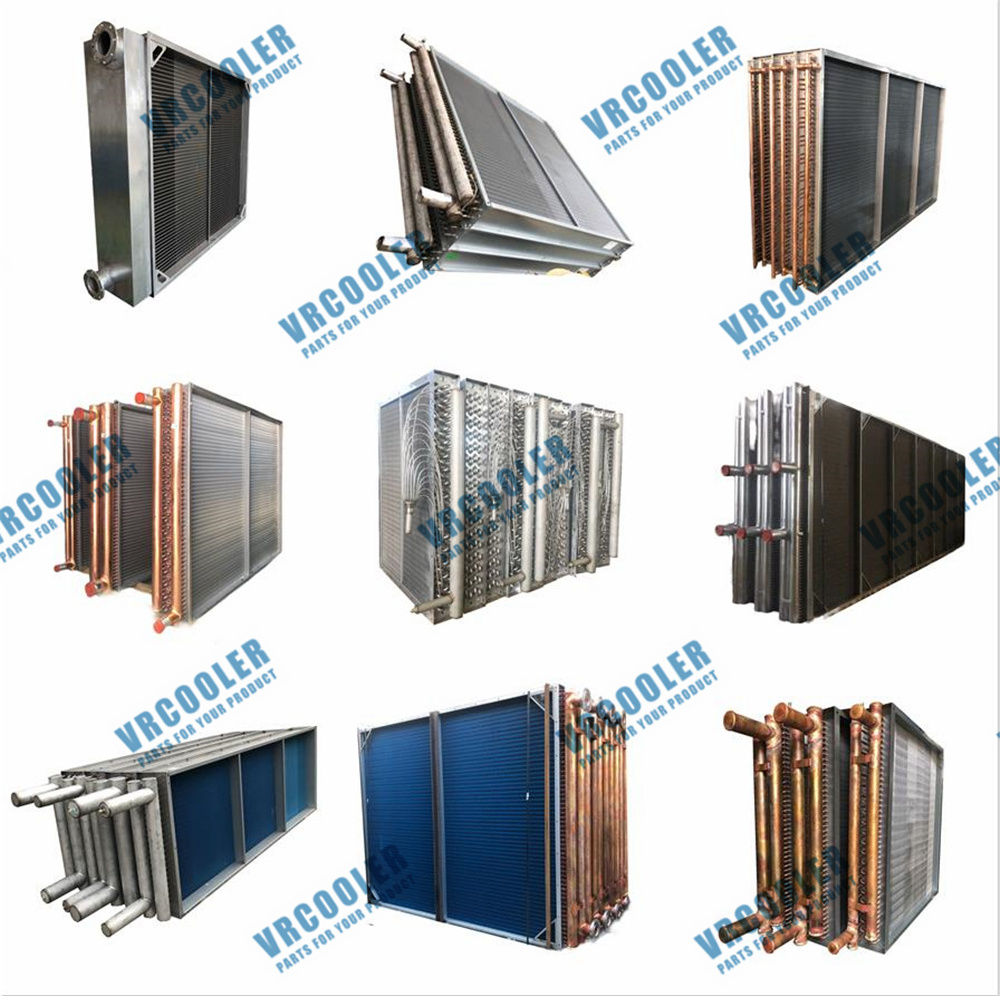

We have customized products for many customers, following are some projects we did before.

We can provide designing data and prodcution drawings.

We promise we use the

design software

sold by a well-known

European HAVC software

company.

Through 8 years of cooperation with them, we have designed, processed and exported dry coolers to various countries all around the world.

All of customers feedback is that the actual cooling performance is almost the same as the theoretical design value.

Customer feedback photos

Russia epoxy coating project

Thailand chiller project

New Zealand gold fin evaporator for heat pump project

Italy unit coil

British Blygold project

Australia coil project

Our Company

MORE THAN 15 YEARS OF SUCCESS

Changzhou Vrcoolertech Refrigeration Co.,Ltd specializes in researching, manufacturing and exporting Heat Exchangers, Evaporators, Condensers, air cooler and other heat transfer equipments for the varied industries since 2004.

OUR MISSION

We are committed to quality products and services to meet our customer's expectations and the needs of industrials. We are dedicated to our mission and goal and we believe in long term business relationship with our customers which is based on integrity, responsiveness and quality

A STRATEGIC LOCATION

Address: Qingsitang, Henglin Town, Wujin Dist, Changzhou, Jiangsu, China.

Tel: +86-0519-81695177

E-mail: info@vrcooler.com ; sales@vrcooler.com

Website: www.vrcoolertech.com ; www.vrcooler.com

QUALITY CERTIFICATES

Since 2004 UNI EN ISO 9001:2008 Quality System

Since 2005 UNI EN ISO 14001:2004 Environmental Management System

Packing and delivery

The normal package is wooden box. If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

FAQ

1.What is your delivery time?

20---30days.

2.What are the payment terms?

50% T/T before production and balance before shipment.

3.What is your warranty?

One year after shipping..

4.What is the valid time of the quotation?

30 days.

5.Can we do our OEM logo?

Yes, we can do OEM logo for you.

Hot Searches