- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.1

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

U Tech

-

Dimension(L*W*H):

-

2600*1920*2550mm

-

Weight:

-

3650 KG

-

Product name:

-

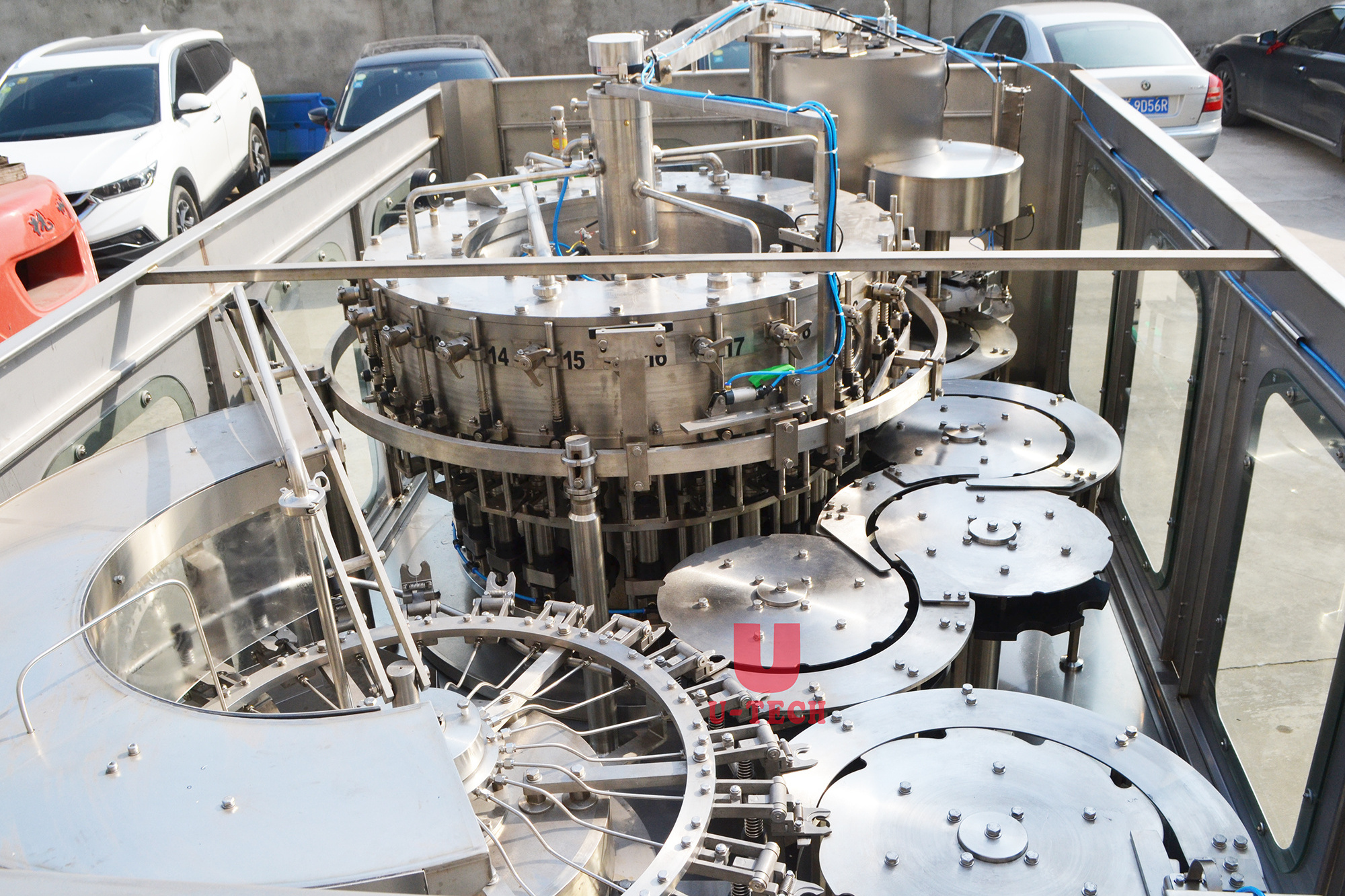

Carbonated Drink Filling Machine

-

Model:

-

DCGF24-24-6

-

Filling range:

-

200-2000ml

-

Capacity:

-

6000 bph

-

Function:

-

Bottle Washing Filling Capping

-

Bottle type:

-

PET Plastic Bottle

-

Filling material:

-

Gas Liquid

-

Usage:

-

Filling Material

-

Processing Types:

-

Cold Filling

Quick Details

-

Machinery Capacity:

-

6000BPH

-

Packaging Material:

-

Wood

-

Filling Material:

-

soda water, carbonated drink

-

Filling Accuracy:

-

±0.1

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

U Tech

-

Dimension(L*W*H):

-

2600*1920*2550mm

-

Weight:

-

3650 KG

-

Product name:

-

Carbonated Drink Filling Machine

-

Model:

-

DCGF24-24-6

-

Filling range:

-

200-2000ml

-

Capacity:

-

6000 bph

-

Function:

-

Bottle Washing Filling Capping

-

Bottle type:

-

PET Plastic Bottle

-

Filling material:

-

Gas Liquid

-

Usage:

-

Filling Material

-

Processing Types:

-

Cold Filling

The machine combines washing, filling and capping three function in a body,used to produce polyester bottled mineral water, purified water, alcoholic beverage machinery and other non-gas beverage machinery. the whole process is automatic, Filling way using the gravity or micro pressure filling, make the speed is faster and more stable, so with the same model our machine output is higher and more efficient. The machine adopts advanced Mitsubishi programmable controller (PLC) to control the machine to run automatically, interworking with inverter running more stable and reliable. the photoelectric sensor detect all part running state, with high degree of automation ,easy operation.

2. Optimum uptime: 30 % reduction in changeover and maintenance downtime

3. Sustainable solution: Reduced filler enclosure and servomotors reduce resource consumption

4. Hygiene improvement through volume control and contactless filling

2. Filling volume adjustable in fine rank, same liquid level after filling

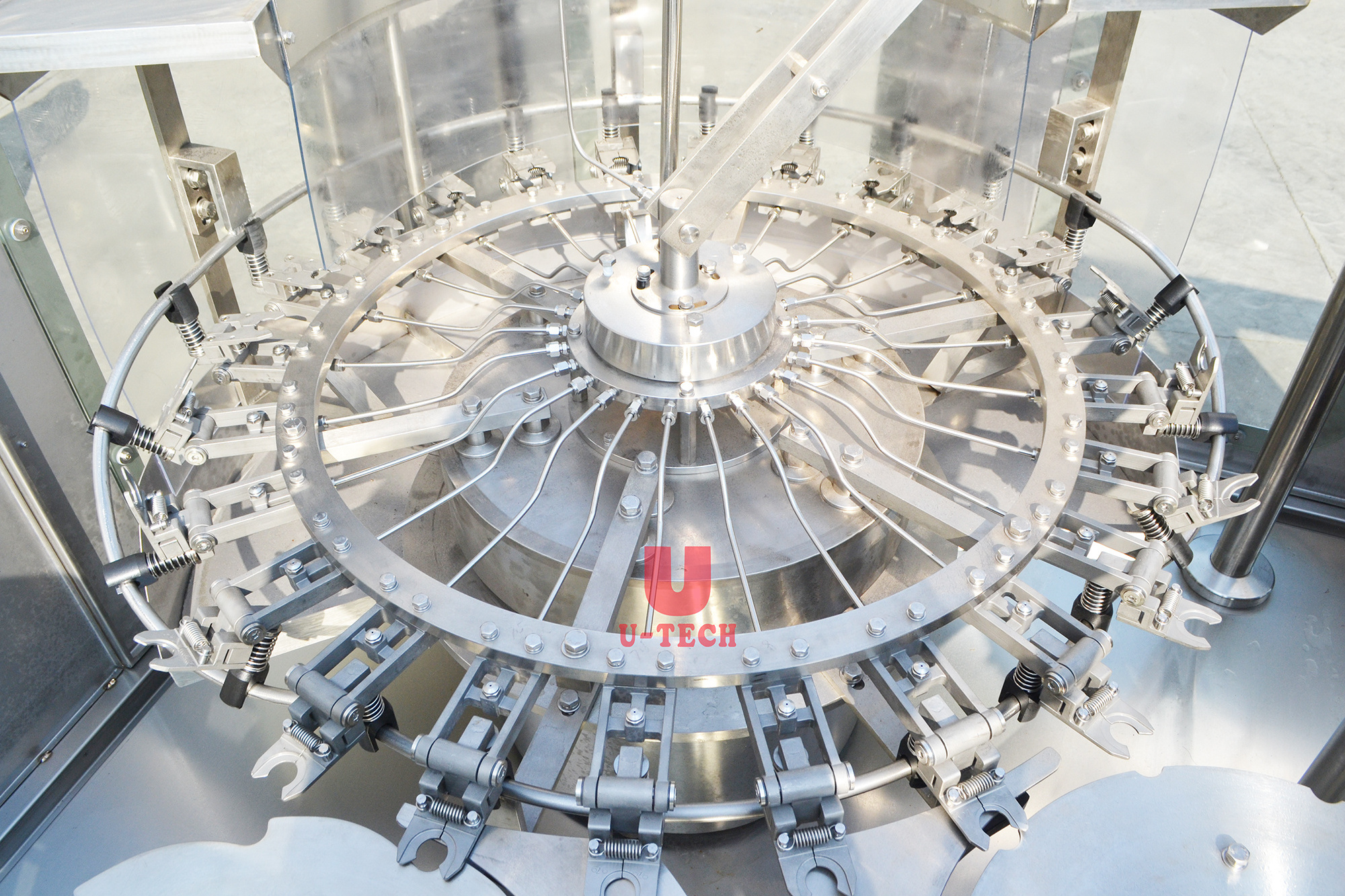

3. All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

4. 304/316 stainless steel filling pump

5. Efficient spray nozzle rinse thoroughly and save water for flushing

3. No bottle no capping

4. Automatic stop when lack of bottle

5. Capping effect is stable and reliable ,Defective rate ≤0.2%

Features:

1. Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

2. Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough.

3. The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

4. High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

5. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6. Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan\'s Mitsubishi, France Schneider, OMRON.

7. Soft Drink Bottling Plant

|

Model

|

DGCF16-12-6

|

DGCF18-18-6

|

DGCF24-24-6

|

DGCF32-32-10

|

|||

|

Production Capacity(B/H)

|

2000-4000

|

4000-6000

|

6000-8000

|

8000-12000

|

|||

|

Filling Precision

|

<=5mm(Liquid Level)

|

|

|

|

|||

|

Filling Pressure(MPa)

|

<0.4

|

|

|

|

|||

|

Polyester Bottle Satandard(mm)

|

φ40-φ80

|

Bottle Diameter: φ50-φ100 Height:150-320

|

|

|

|||

|

Suitable Cap Shape

|

Plastic Screw Cap

|

|

|

|

|||

|

Water Pressure of Washing Bottle(MPa)

|

0.18-0.25

|

|

|

|

|||

|

Water Consumption for Washing Bottle(kg/h)

|

1300

|

2000

|

2500

|

3000

|

|||

|

Spraying Position

|

5

|

5

|

6

|

12

|

|||

|

Dripping Bottle Position

|

2.5

|

3.0

|

3.5

|

7

|

|||

|

Gas Consumption

(m³/min)

|

0.3

|

0.4

|

0.4

|

0.5

|

|||

|

Total Power(kw)

|

5.03

|

5.03

|

6.57

|

8.07

|

|||

|

Total Weight(kg)

|

2000

|

3000

|

4000

|

5000

|

|||

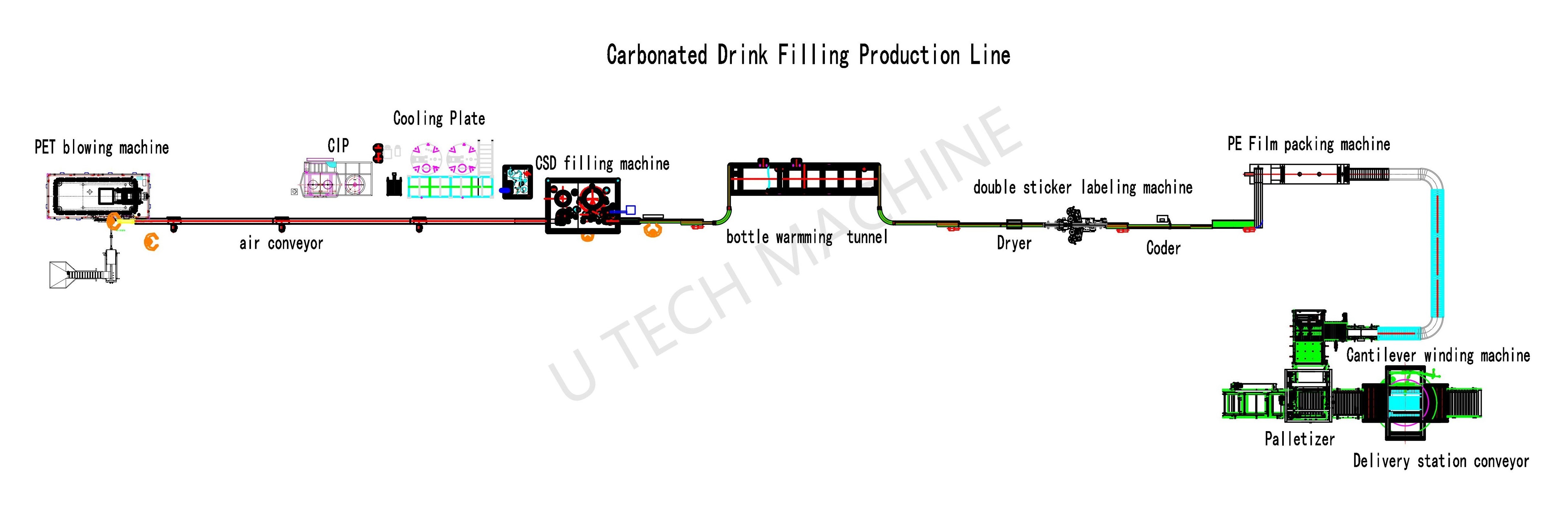

Beverage mixer

Auto bottle blowing machine

<2>Perfect heating system design decrease power consumption.

<3>Special oven design helps power-saving and easy maintain.

Bottle warming machine

Double station shrink sleeve labeling machine

Zhangjiagang U Tech Machine Co., Ltd. is a manufacturer of filling machine and packing with well-equipped testing facilities and strong technical force. With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in beverage and other packing equipment.

Our products include: liquid filling machines (water, fruit juice/tea, carbonated drink, oil, alcohol, plant protein drink, etc.), barreled filling line (3-5 gallon) water treatment machines, labeling & packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC...) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.

on.