- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/customized

-

Dimension(L*W*H):

-

3000*1500*1400mm

-

Weight:

-

750 KG

-

Product name:

-

Stainless Sateel Linear Perlite Vibrating Screens Sifter Machine

-

Material:

-

Carbon Steel/ Stainless Steel 304

-

Usage:

-

Sand Screening

-

Function:

-

Screening\separation\sorting\sieving

-

Cleaning system:

-

Bouncing Ball

-

Installation:

-

Under Technical Guidance

-

Feature:

-

Simple Operation

-

Applicable Material:

-

Powder, Liquid, Granule

-

Advantage:

-

Long Working Life

-

Mesh size:

-

2-200 Mesh

Quick Details

-

Type:

-

LINEAR

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DY

-

Voltage:

-

380V/customized

-

Dimension(L*W*H):

-

3000*1500*1400mm

-

Weight:

-

750 KG

-

Product name:

-

Stainless Sateel Linear Perlite Vibrating Screens Sifter Machine

-

Material:

-

Carbon Steel/ Stainless Steel 304

-

Usage:

-

Sand Screening

-

Function:

-

Screening\separation\sorting\sieving

-

Cleaning system:

-

Bouncing Ball

-

Installation:

-

Under Technical Guidance

-

Feature:

-

Simple Operation

-

Applicable Material:

-

Powder, Liquid, Granule

-

Advantage:

-

Long Working Life

-

Mesh size:

-

2-200 Mesh

Product Display

Product Parameters

|

Model

|

W*L (mm)

|

Power (Kw)

|

Screen surface angle

|

Layer

|

|

DZSF-520

|

500*2000

|

2*(0.4 - 0.75)

|

0-7 degree

|

1-5 layers

|

|

DZSF-1020

|

1000*2000

|

|

|

|

|

DZSF-1030

|

1000*3000

|

2*(1.1 - 1.5)

|

|

|

|

DZSF-1250

|

1200*5000

|

2*(1.1 - 2.2)

|

|

|

|

DZSF-1560

|

1500*6000

|

2*(2.2 - 3.7)

|

|

|

|

DZSF-1845

|

1800*4500

|

|

|

|

|

DZSF-2260

|

2200*6000

|

|

|

|

Customize as client's demand!

Looking forward to your inquiry!

Product Description

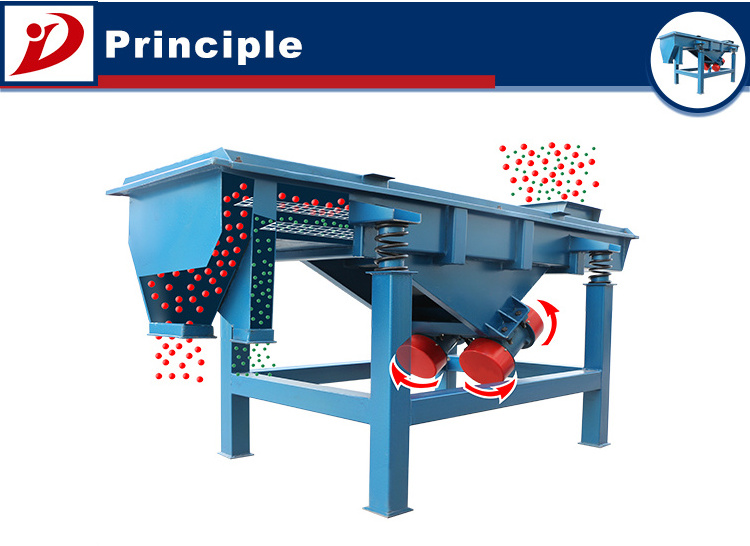

Working Principle

DZSF series linear vibrating screen

uses vibration motor as vibration source, the materials is rose and moved in the straight at the same time. The materials are entered into entrance equality, and then go through screen to create the materials with different sizes, which was discharged from different gates. It is suitable for low consuming, high output, and simple structure, easily maintain all-closed structure, no powder dispersed, automobile discharged.

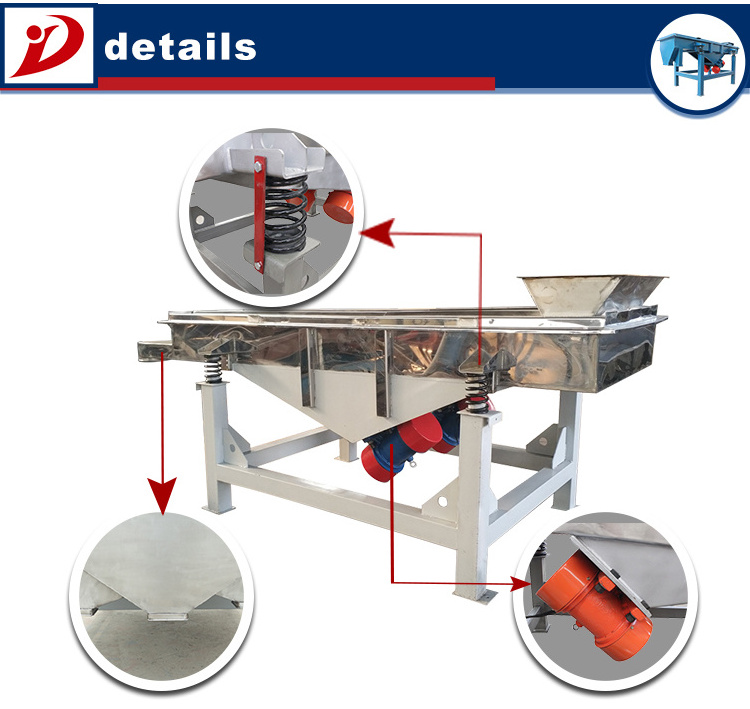

Features

1. Small volume, light weight, simple structure, convenient installation, easy maintenance.

2. Low noise, low consumption, high efficiency and low cost.

3. High accuracy of screening, no dust pollution, environmental protection.

4. Replaced variety of screen and long service life.

Application

Our linear vibrating screen

can be used for processing starch powder, sugar powder, sale, rice flour, milk power, soybean mile, sauce, fruit juice, resin powder, paint, industrial chemicals, detergent powder, cosmetic, Chinese medicine powder, aluminum powder, lead powder, copper powder, alloy metal powder, electrode powder, and so on.

Company Introduction

Xinxiang Dayong Vibration Equipment Co., Ltd.

, a famous manufacturer of making food machines, industrial machines and agriculture machines in China, is a research, manufacturing and trade integrated modern enterprise.

Our company has a professional team, and has in-depth study in the application of all kinds of projects, food machinery, etc. Our brand, DY, has been the well-known brand after outstanding development. Our company has diversified equipment, mainly include vibration screen, conveyor, elevator and crusher.

FAQ

Q: What information do I need to provide for getting an accurate quotation for linear

vibrating screen sieve?

1. Material’s name, bulk density, and water content

2. Capacity you required___kg/h

3. What’s the purpose for our machine? Filtering, removing impurities or classification?

4. How many layers do you need?

vibrating screen sieve?

1. Material’s name, bulk density, and water content

2. Capacity you required___kg/h

3. What’s the purpose for our machine? Filtering, removing impurities or classification?

4. How many layers do you need?

5. The mesh size for each layer

6. Voltage and frequency

Q: How long for the delivery time?

A: 5-10 working days for conventional products.

Q: How long for warranty time?

A: 18 months from the shipping date.

6. Voltage and frequency

Q: How long for the delivery time?

A: 5-10 working days for conventional products.

Q: How long for warranty time?

A: 18 months from the shipping date.

Hot Searches