- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

100%

-

Voltage:

-

380/50HZ

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Worlds Filling

-

Dimension(L*W*H):

-

2360*1830*2250

-

Weight:

-

3800 KG

-

Function:

-

Washing Filling Capping

-

Filling material:

-

carbonated drinks

-

Bottle type:

-

PET Bottle

-

Filling volume:

-

200-2000ml

-

Production capacity:

-

3000-5000

-

Control:

-

PLC+ Touch Screen

-

Advantage:

-

High Effective

-

Material:

-

Stainless Steel 304/316

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH

-

Packaging Material:

-

Plastic

-

Filling Material:

-

carbonated drinks

-

Filling Accuracy:

-

100%

-

Voltage:

-

380/50HZ

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Worlds Filling

-

Dimension(L*W*H):

-

2360*1830*2250

-

Weight:

-

3800 KG

-

Function:

-

Washing Filling Capping

-

Filling material:

-

carbonated drinks

-

Bottle type:

-

PET Bottle

-

Filling volume:

-

200-2000ml

-

Production capacity:

-

3000-5000

-

Control:

-

PLC+ Touch Screen

-

Advantage:

-

High Effective

-

Material:

-

Stainless Steel 304/316

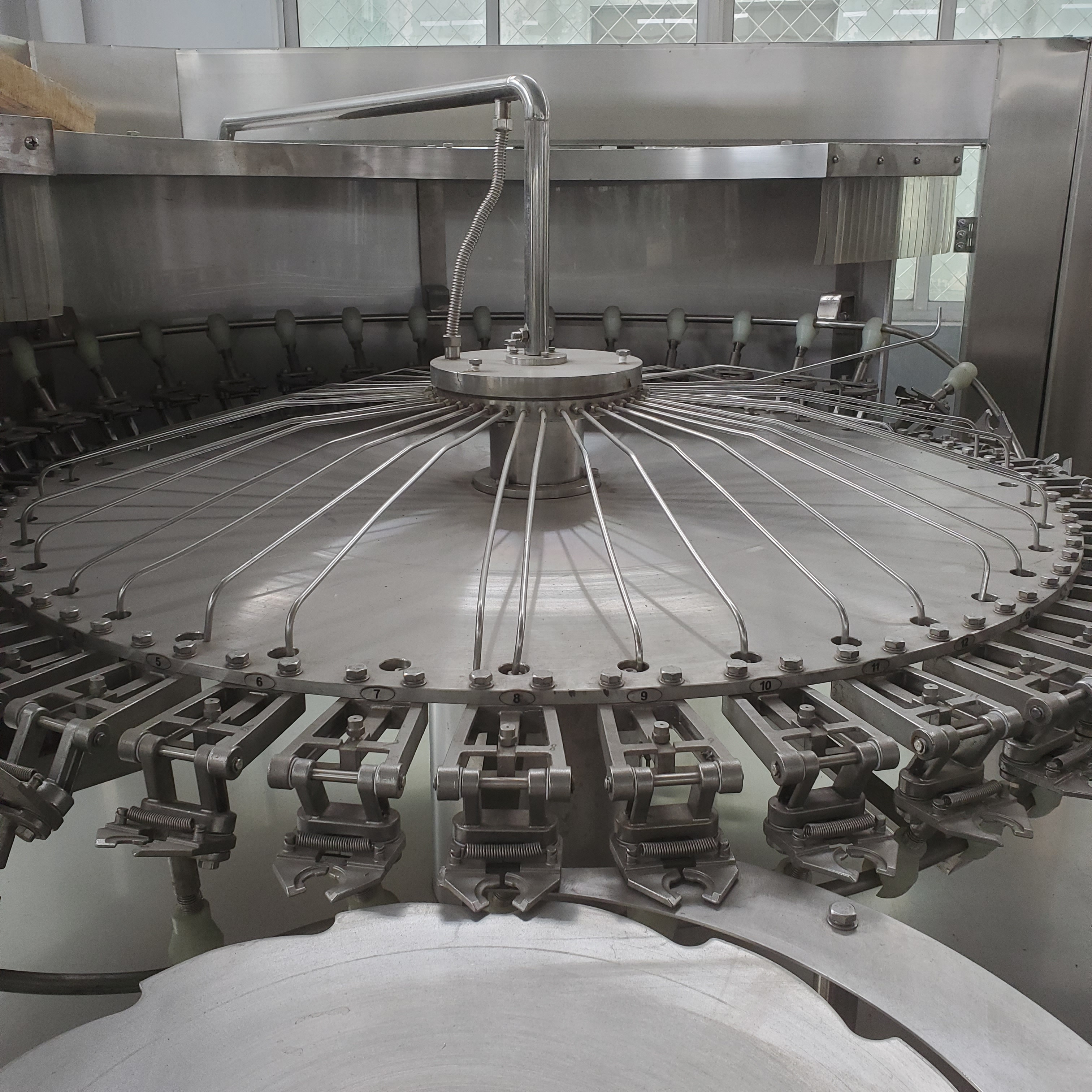

Introduction

This DCGF series rotary machine is specially designed for carbonated drinks , such as coca cola, pepsi, soda water, etc. I t contains automatic bottle washer, bottle filler, bottle capper .

Features:

1

. The whole filling line is suitable for same bottle diameter different bottle height, easy to adjust. When with different bottle diameter, only needs to set with some extra bottle change parts to share, easy to change.

2

. The machine

is made of

the high quality of SUS304 material, meet with GMP standard,

which

has long lifespan.

3

. The

machine

is automatic with electromagnetic speed-regulator, speed adjustable

, and w

here contact with the liquid part are made of stainless steel (

SUS304 or

S

L

3

16

), in line with food hygiene requirements.

4

. Bottles transmission adopt clip bottleneck technology, bottle-shaped transform

do

not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough.

5 . The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

6 . Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

7 . Super-low star wheel structure can highly improve the strength of the whole machine.

8 . A dopt s advanced PLC automatic control technology, the key electrical components from famous company such as Mitsubishi, France Schneider, OMRON, etc .

9. Adopt s magnetic clutch screw capping system , torque adjustable to ensure capping quality.

Technique parameter:

|

DGCF16/12/6 |

DGCF18/18/6 |

DGCF24/24/8 |

DGCF32/32/10 |

DGCF40/40/10 |

DGCF50/50/12 |

DGCF60/60/15 |

||||||

|

Production Capacity:500ml(b/h) |

2000-3000 |

3000- 4 000 |

5 000- 6 000 |

6 000- 8 000 |

10000-12000 |

12000-15000 |

15000-18000 |

|||||

|

Filling precision |

≤5mm (liquid level) |

|

||||||||||

|

Filling pressure(Mpa) |

<0.4 |

|

||||||||||

|

Suitable bottle standard:(mm) |

Bottle diameter: φ40-φ80, bottle height: 130-280mm |

Bottle diameter: φ50-φ100 bottle height: 150-320mm |

Bottle diameter: φ50-φ1 1 0 bottle height: 200 -3 8 0mm |

|

|

|||||||

|

Suitable cap standard:(mm) |

Plastic screw cap, φ50-φ110 |

|

||||||||||

|

Pressure for washing bottle(Mpa) |

0.18-0.25 |

|

||||||||||

|

Water consumption for washing bottle(Kg/h) |

1300 |

2000 |

2500 |

3000 |

3500 |

4000 |

4500 |

|||||

|

Gas source pressure(Mpa) |

0.4 |

|

||||||||||

|

Gas consumption(m 3 /min) |

0.3 |

0.4 |

0.4 |

0.5 |

0.6 |

0.7 |

0.8 |

|||||

|

Total power(Kw) |

5.03 |

5.03 |

6.57 |

8.07 |

9.52 |

11.57 |

16.02 |

|||||

|

Overall Dimension(L×W×H, mm) |

2100×1500×2200 |

2450×1800×2200 |

2750×2180×2200 |

3600×2200×2200 |

4600x3800x2500 |

5000x4700x2500 |

6500x5400x2500 |

|||||

|

Total Weight:(kg) |

2000 |

3500 |

5500 |

8000 |

8500 |

10000 |

12500 |

|||||

Main Machine

Washing

Filling

Ca

Ca

Capping

Touch Screen

Electrical part