- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

250 mm

-

Width of Working Table (mm):

-

100 mm

-

Dimension:

-

3200*1800*2500

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

GENUO

-

Year:

-

2023

-

Weight (KG):

-

4200

-

Motor Power (kw):

-

6.5 kw

-

Marketing Type:

-

New Product 2024

-

Product name:

-

CNC Press Brake Machine

-

After-sales Service Provided:

-

Online Support

-

CNC or not:

-

CNC BendingMachine

-

Color:

-

Customer Choose

-

Main Motor:

-

Siemens Germany

-

Power:

-

7.5kw 10kw 15kw 20kw

-

Electrical components:

-

Schneider

-

Hydraulic System:

-

Bosch Rexroth Germany

-

Certification:

-

ISO 9001:2000

-

Bending length:

-

2500mm/3200mm/4000mm

Quick Details

-

Machine Type:

-

Synchronized

-

Length of Working Table (mm):

-

3200

-

Slider Stroke (mm):

-

100 mm

-

Throat Depth (mm):

-

250 mm

-

Width of Working Table (mm):

-

100 mm

-

Dimension:

-

3200*1800*2500

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

GENUO

-

Year:

-

2023

-

Weight (KG):

-

4200

-

Motor Power (kw):

-

6.5 kw

-

Marketing Type:

-

New Product 2024

-

Product name:

-

CNC Press Brake Machine

-

After-sales Service Provided:

-

Online Support

-

CNC or not:

-

CNC BendingMachine

-

Color:

-

Customer Choose

-

Main Motor:

-

Siemens Germany

-

Power:

-

7.5kw 10kw 15kw 20kw

-

Electrical components:

-

Schneider

-

Hydraulic System:

-

Bosch Rexroth Germany

-

Certification:

-

ISO 9001:2000

-

Bending length:

-

2500mm/3200mm/4000mm

Products Description

New Machine description

GENUO's Excellent ESC series is the latest generation of high-performance synchronized

CNC Press Brake.Combining GENUO's independently developed controller,it maximizes

value creation and reduces costs.User-friendly operating system and first-class design.

Adhering to the philosophy of GENUO (Details Create Quality).

With super quality and high precision, it also has a huge competitive advantage.

More convenient to use, high cost performance!

To Learn More

Click Here >>

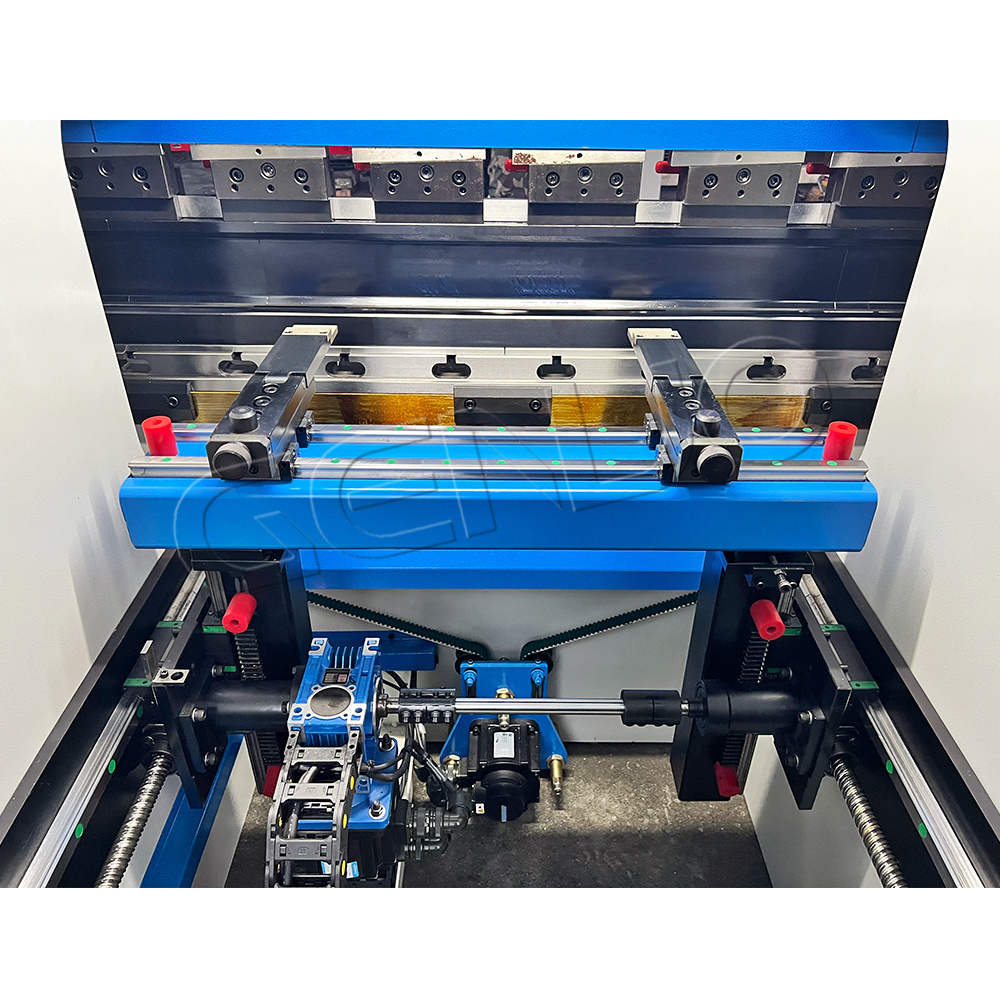

Auto Crowing System :To confrm a constant bend angle, manual or CNC crowning

is essential

which will offset potential deviations and allow for possible tooling wear

to maintain parallel

contacting surfaces.

CNC crowning systems allow the press brake

control to be pre

programmed with machine characteristics and defection data.

Adjust the calculate and setting

accordingly for different characteristics of

different materials.

Backgauge System:Establishing the right back gauge for your projects will allow for

increased part production and precision.From intricate parts which typically require

more axes to large quantities that require more time and therefore increased cost,

the correct back gauge for each job is essential to lowering costs per part which

ultimately benefts your bottom line.

|

Standard Equipment

|

Optional Equipment

|

|

◆

GENUO ETC-16T 4 Axis CNC Control

|

◇ETC-16T 5 Axis/7 Axis CNC Control

|

|

◆Integral welded rigid high tensile steel frame

|

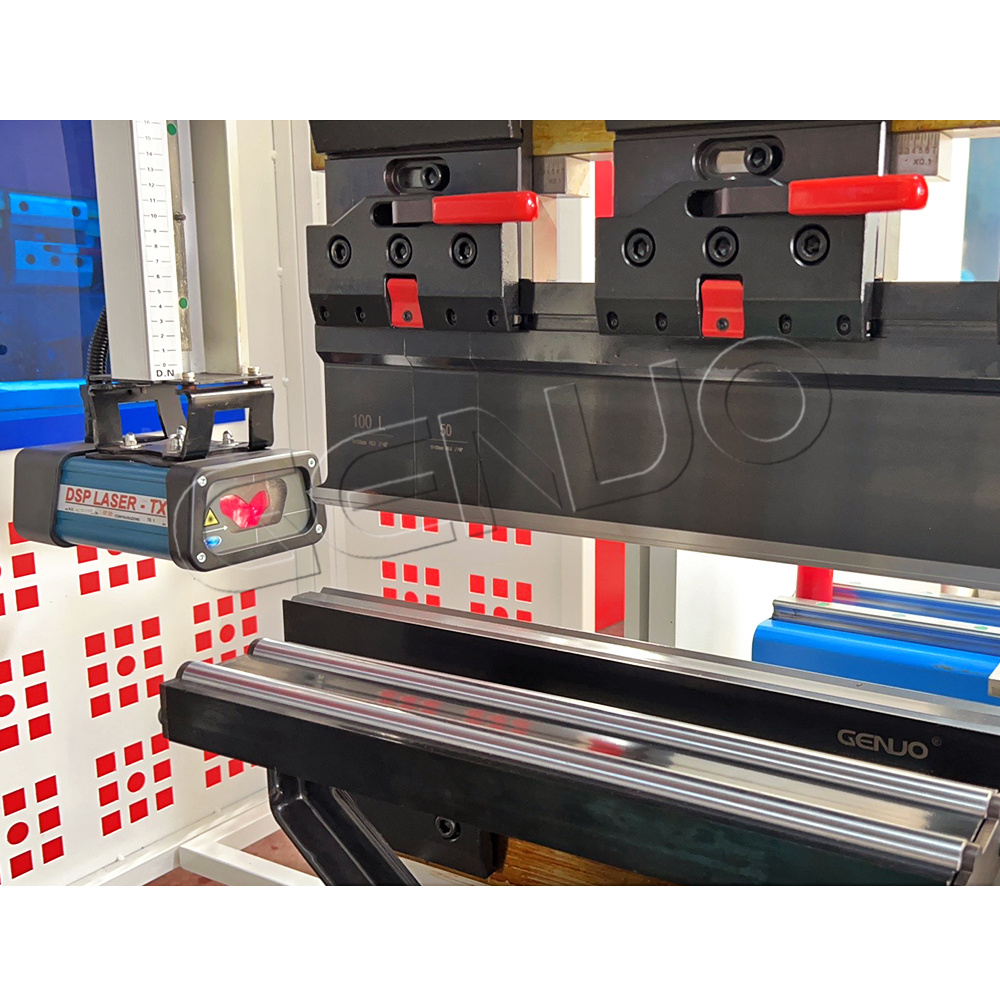

◇DSP or SDKELI Lasersafe protection guard

|

|

◆

High precision Y1,Y2 axis synchronized closed-loop feedback

|

◇Energy saving & low noise main servo SVP control

|

|

◆Accurate X axis back gauge system

|

◇2 Axis(X,R) or 4-Axis (X,R,Z1,Z2)back gauge

|

|

◆

CNC Motorized crowning system

|

◇The CNC Bending Sheet Follower

|

|

◆European-style punch and 4V/2V/1V Dies

|

◇WILA type top and bottom tool clamping system

|

|

◆Fast punch clamps and movable sliding front support

|

◇Bending tools management cabinet or trolley

|

Product Paramenters

|

Model

|

Nominal Pressure

(kn)

|

Bending

Length

(mm)

|

Distance Between Columns

(mm)

|

Ram Strokes

(mm)

|

Throat Death

(mm)

|

Open Height

(mm)

|

Motor Power

(kw)

|

Overall Dimension

(L x W x H)

(m)

|

||||||||

|

ESC

|

/

|

A

|

B

|

C

|

D

|

E

|

/

|

/

|

||||||||

|

40T1600

|

400

|

1600

|

1250

|

150

|

300

|

420

|

4

|

2.0*1.8*2.4

|

||||||||

|

63T2500

|

630

|

2500

|

1960

|

150

|

320

|

420

|

5.5

|

2.9*1.8*2.4

|

||||||||

|

100T3200

|

1000

|

3200

|

2600

|

200

|

400

|

480

|

7.5

|

3.9*1.9*2.6

|

||||||||

|

100T4000

|

1000

|

4000

|

3200

|

200

|

400

|

480

|

7.5

|

4.6*1.9*2.7

|

||||||||

|

125T3200

|

1250

|

3200

|

2600

|

200

|

400

|

480

|

11

|

3.9*1.9*2.6

|

||||||||

|

160T3200

|

1600

|

3200

|

2600

|

200

|

400

|

480

|

11

|

3.9*1.9*2.6

|

||||||||

|

200T3200

|

2000

|

3200

|

2600

|

200

|

400

|

480

|

15

|

4.7*1.9*2.8

|

||||||||

|

320T4000

|

3200

|

4000

|

3200

|

200

|

400

|

480

|

22

|

4.8*2.2*3.2

|

||||||||

|

400T6000

|

4000

|

6000

|

4900

|

320

|

500

|

600

|

30

|

6.5*2.8*4.5

|

||||||||

|

The above data is only for reference only,to prevail in kind. More specifications available.

Please click here!

|

|

|

|

|

|

|

|

|

||||||||

Recommend Products

Hot Searches