- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

860*960*1955

-

Product name:

-

PSA Nitrogen Generator

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Video technical support

-

Free spare parts:

-

Yes

-

Online support:

-

Yes

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Cryo Chains

-

Production Rate:

-

3L/h

-

Voltage:

-

380

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

860*960*1955

-

Product name:

-

PSA Nitrogen Generator

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Video technical support

-

Free spare parts:

-

Yes

-

Online support:

-

Yes

PSA, Membrane Filtration, Cryogenic Process Oxygen Nitrogen Generator Plant:

Psa Liquid Nitrogen Oxygen Generator Machine Medical Oxygen Generator 50nm3/H

Product Description

PSA Nitrogen Oxygen Generator Plant:

Process characteristics of PSA oxygen nitrogen generators:

(1) PSA nitrogen oxygen production equipment is characterized by wide application of air source, high product purity, simple process, high degree of automation, low operating cost, etc.

(2) The compressed air purification module has a long service life and is easy to replace and maintain.

(3) The outlet flow of the nitrogen making equipment is large, and the outlet pressure can be adjusted within the set range.

(4) Can open and stop at any time according to the production situation.

(5) nitrogen purity >99.99% can be achieved through psa, and no nitrogen purification equipment is required.

(6) Add nitrogen purification device: hydrogenation purification! Add carbon purification, the purity of qualified product gas can reach ≥99.9995%.

|

Product Name

|

PSA Nitrogen Generator

|

|

Nitrogen Output

|

5~8000Nm3/h

|

|

Nitrogen Purity

|

95~99.9999%

|

|

Nitrogen Pressure

|

0~0.8MPa(Can be extended to 1.0 to 15.0 MPa)

|

|

Nitrogen Dew Point

|

≤-45~-70℃

|

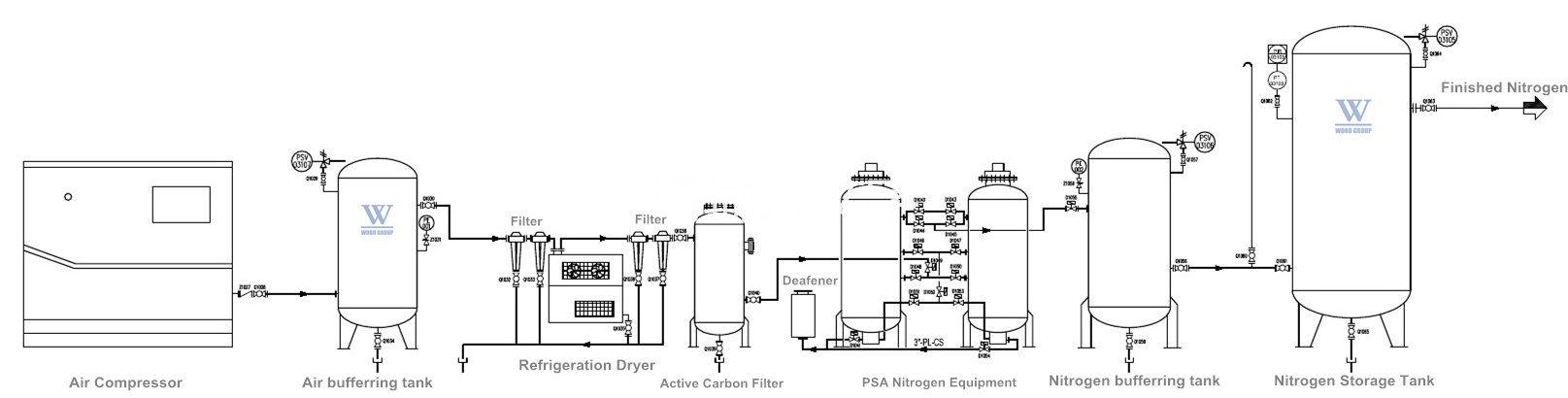

Based on the principle of pressure swing adsorption (PSA), high-quality carbon molecular sieves are used as adsorbents. Under certain pressure, due to kinetic effects, oxygen diffuses much faster than nitrogen in the micropores of carbon molecular sieves. Before reaching adsorption equilibrium, oxygen is extensively adsorbed by the carbon molecular sieves, while nitrogen molecules are enriched in the gas phase, achieving oxygen-nitrogen separation. As the adsorption capacity of carbon molecular sieves for oxygen varies with pressure, reducing the pressure allows desorption of the adsorbed oxygen molecules, regenerating the carbon molecular sieves for reuse. The process involves two adsorption towers: one for nitrogen production and the other for desorption and regeneration. PLC intelligent program controllers control the opening and closing of pneumatic angle seat valves, enabling the two towers to alternate cyclically, continuously producing high-quality nitrogen gas.

Products Details

Project Case

Applications

Applications for nitrogen generator machine:

In addition to synthetic ammonia, nitrogen is usually used as a protective gas widely used in metallurgy, chemical industry, coal, food, medicine, electronics, magnetic materials, transportation, heat treatment, tires, thermoelectricity, aviation and other industries.

Psa nitrogen adsorption equipment for petroleum and petrochemical industry;

Tyre nitrogen filling pressure converter nitrogen adsorption equipment;

Special fire - fighting nitrogen equipment for coal mine;

Pressure change adsorption nitrogen machine for medicinal use;

Nitrogen production equipment for food industry;

Nitrogen making machine in electronic magnetic material industry.

Related Products

Hot Searches