- Product Details

- {{item.text}}

Quick Details

-

Applications:

-

pasta doritos bugles salad etc.

-

Screw diameter:

-

65mm;70mm;85mm;95mm

-

Energy source:

-

Electricity/Gas/Diesel/LPG/Steam

-

Motor brand:

-

Siemens, ABB or customized

-

Inverter brand:

-

Delta, Siemens, ABB or customized

-

worker:

-

2-3 workers to operate

-

Product name:

-

crispy chips bugles making machine

-

Application:

-

snack machine

Quick Details

-

Place of Origin:

-

Shandong, China

-

Production Capacity:

-

100kg-200kg/h

-

Raw materal:

-

corn starch, potato starch,etc.

-

Applications:

-

pasta doritos bugles salad etc.

-

Screw diameter:

-

65mm;70mm;85mm;95mm

-

Energy source:

-

Electricity/Gas/Diesel/LPG/Steam

-

Motor brand:

-

Siemens, ABB or customized

-

Inverter brand:

-

Delta, Siemens, ABB or customized

-

worker:

-

2-3 workers to operate

-

Product name:

-

crispy chips bugles making machine

-

Application:

-

snack machine

Small frying crispy 3d corn bugles pellets fried chips snacks food machine production line bugles making extruder machine

1. Description

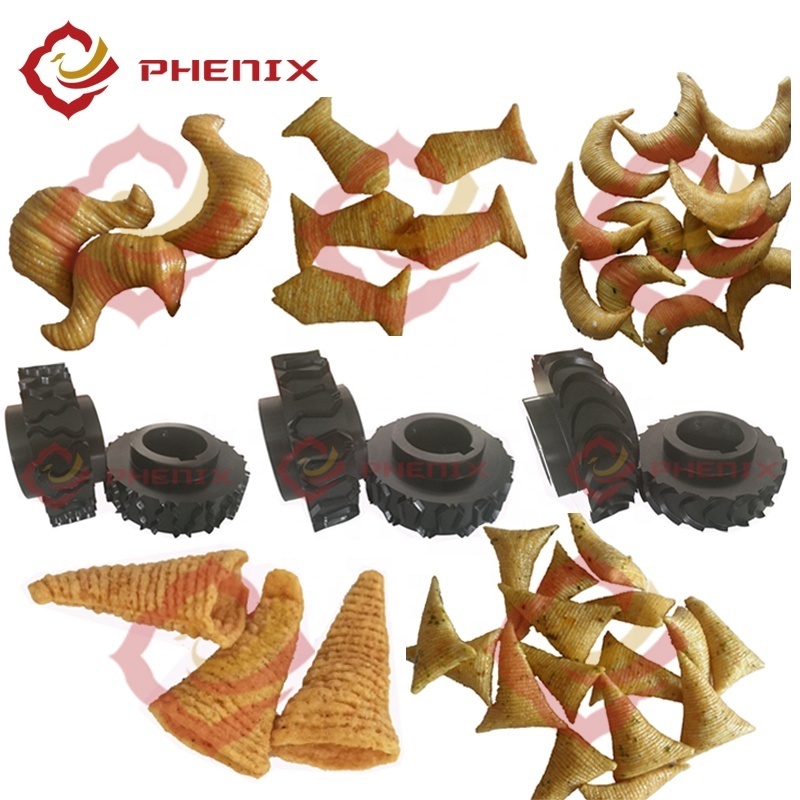

Crispy chips bugles making machine can be wheat flour, potato starch, potato powder, corn starch and so on. Only by changing machine die, the fried pellet chips snack food making machine can produce different shaps of food, Such as crisp pea, shell, screw, square tube, round tube, wave etc. All the shapes are very popular in the market.

2.

Flow chart:

Mixing system---Extrusion system---Cutting system---Frying system----Flavoring system---Packing system

3. Technical Parameters

| Model | Power(kw) | Capacity(kg/h) | Dimension(mm) |

| PX65 | 80 | 100-150 | 21000x1200x2200 |

| PX70 | 110 | 200-240 | 2300x1500x2200 |

| PX85 | 130 | 450-500 | 2800x3500x4300 |

4.Machine & Spare parts Picture

Outside package: Standard export wooden case. Inner package: stretch film

a. We can keep product design in the same level with internationally advanced technology consistently.

b. We have high diathesis staff and excellent processing equipment, and quality control runs through the whole production process from parts stock to the beginning of production.

c. We can guarantee customers superior quality machines up to design requirements and perfect working state.

d. Our technicians can also provide all kinds of relevant technology to make the food production clean, healthy and safe.

e. We will dispatch our technicians to your factory to guide you installation and commissioning work and training your operator.

f. We provide 1 year complete Guarantee and life-time maintenance service.