* High number of rotations (15-35 rpm)

* Single shaft with parallel axis engine reducer

* Configurable automatic gear reversal

* Bearings outside of the cutting chamber

* Automatic greasing managed by PLC

* Use of high quality steels

* Configurable blades for thickness and number of teeth

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Fante

-

Voltage:

-

380/50/3 or customized

-

Dimension(L*W*H):

-

See technical parameter

-

Power (kW):

-

3

-

Weight (T):

-

0.5

-

Application:

-

Recycle Waste Plastic

-

Name:

-

industrial plastic tire metal scrap shredder machine

-

Usage:

-

plastic/wood/rubber/paper/metal and etc.

-

Color:

-

Client's Requirements

-

Crushing material:

-

Types Waste Plastic

-

Blades material:

-

9CrSi/D2/SKD-11/ Customized

-

Other name:

-

Double Shaft Plastic shredder

-

Final product:

-

1-10 Cm

-

After-sales Service Provided:

-

Video technical support

Quick Details

-

Max.Production Capacity (kg/h):

-

300

-

Place of Origin:

-

Jiangsu, China

-

Production Capacity (kg/h):

-

150 - 660 kg/h

-

Brand Name:

-

Fante

-

Voltage:

-

380/50/3 or customized

-

Dimension(L*W*H):

-

See technical parameter

-

Power (kW):

-

3

-

Weight (T):

-

0.5

-

Application:

-

Recycle Waste Plastic

-

Name:

-

industrial plastic tire metal scrap shredder machine

-

Usage:

-

plastic/wood/rubber/paper/metal and etc.

-

Color:

-

Client's Requirements

-

Crushing material:

-

Types Waste Plastic

-

Blades material:

-

9CrSi/D2/SKD-11/ Customized

-

Other name:

-

Double Shaft Plastic shredder

-

Final product:

-

1-10 Cm

-

After-sales Service Provided:

-

Video technical support

|

Model

|

FT2S-300*180

|

FT2S-400*180

|

FT2S-500*180

|

|

Motor

|

3KW-4,2set

|

4KW-4,2set

|

7.5KW-4,2set

|

|

Reducer

|

JKA77,2set

|

JKA87,2set

|

JKA97,2set

|

|

Control panle

|

PLC System protection

|

PLC System protection

|

PLC System protection

|

|

Input Speed(rpm)

|

16

|

17

|

15

|

|

Input Torque(Nm)

|

3107

|

3952

|

8255

|

|

Input shaft diameter(mm)

|

Φ60

|

Φ60

|

Φ70

|

|

Tool size( mm)

|

Φ180*12

|

Φ180*15

|

Φ200*20

|

|

Number of tools( pcs)

|

25

|

26

|

25

|

|

Feed port size( mm)

|

500*500*300

|

500*600*300

|

600*700*400

|

|

Dimension (mm)

|

1200*500*1300

|

1400*500*1450

|

1600*600*1550

|

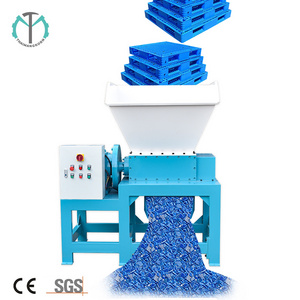

Fante Small waste shredder is very popular for house hold, the size of breaking chamber is only 400*400/300*200/200*200mm, this model suitable for home,small scale recycling centers.The capacity for crushing is around 350kg/hr. It features with small size,soft price,quick lead time, perfect performance & multi-application. With this mini shredder you can save lots of space andcost of transportation, by selling crushed materials will bring you more profit.

Technologies:

Introduction of waste wood pallet double shaft shredder

Double shaft shredder also called cutting shredder through cutting and extrusion to reduce the material size,widely used in the waste plastic,scrape rubber,scrap metal,wood,garbage and other large volume of waste.our company provide shredding machine equipment with mature technology,advanced design and reliable quality to crush and reduce volume before waste recycling.This double shredding machine by the PLC automatic control,with which has start, stop,reverse andautomatic reverse in overload condition.

Main Features of Scrap Metal/Root Crusher Waste Car Shredder Machine For Sale

1.Low noise, less dust with high capacity.

2.Special thick plate precision machining combination frame, large angle hexagonal column of the strong rotation axis, large diameter solid into the hopper, so you can safely put into large raw materials.

3. In the thickness, shape, arrangement and other aspects of the design and processing of a unique rotary knife, shear strong,sharp blade, can be highly efficient broken.

4. Unique multiple combination sealing structure effectively blocks the contact of broken material and grease.

5. The moving blade material is made of special alloy tool steel forging blanks, precision machining, multiple heat treatments and low temperature freezing heat treatment technology.

2.Special thick plate precision machining combination frame, large angle hexagonal column of the strong rotation axis, large diameter solid into the hopper, so you can safely put into large raw materials.

3. In the thickness, shape, arrangement and other aspects of the design and processing of a unique rotary knife, shear strong,sharp blade, can be highly efficient broken.

4. Unique multiple combination sealing structure effectively blocks the contact of broken material and grease.

5. The moving blade material is made of special alloy tool steel forging blanks, precision machining, multiple heat treatments and low temperature freezing heat treatment technology.

Frequently asked questions when buying products

Q: How many years have your factory been established?

A:Our factory established from 2015, but most of our engineers are working in this industry over 20 year.

Q: How long is your delivery time ?

A:we have a few stock .but if produce,1 set for normal machine need about 3-7 working days , if 1 or more containers, need about 15-20 working days.

Q:how long is the warranty?

A:Within 1 year from date of the factory, if parts failure or damage(because of the quality problem ,except wearing parts),our company provide these parts for free.

Q:What is your payment term ?

A:TT 100% before shipment ,LC at sign, Western Union or Trade Assurance order recommended.

Hot Searches