- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

110/220/380V

-

Power:

-

2.2 KW

-

Key Machines:

-

Injection molding machine,mould,etc

-

Product name:

-

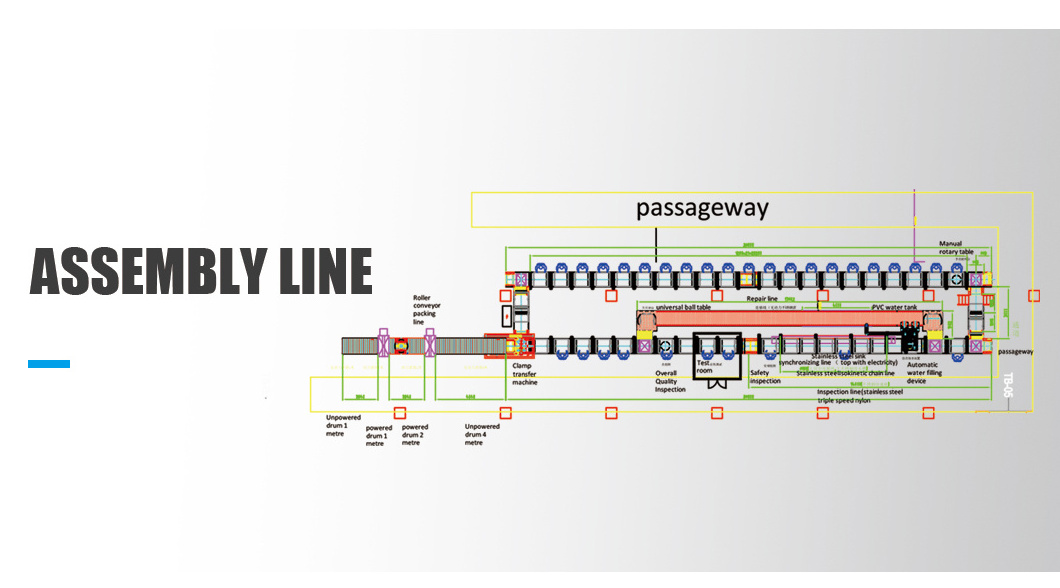

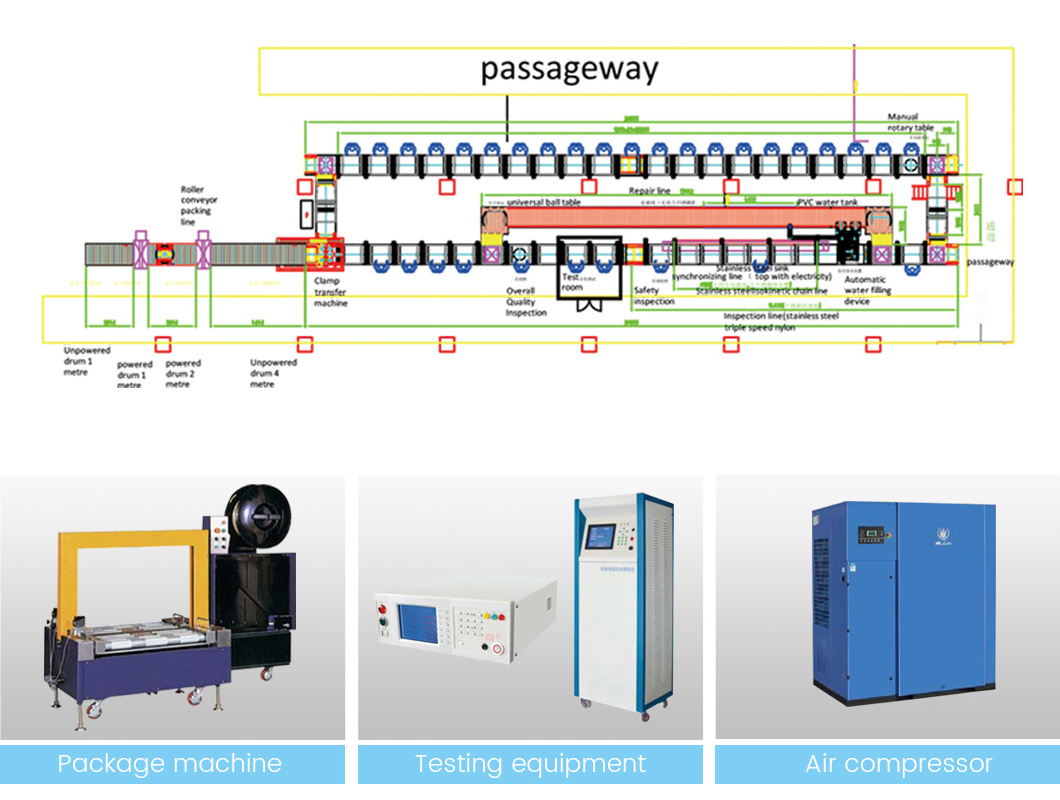

Washing Machine Assembly Line

-

Application:

-

Washine Machines

-

PAYMENT TERM:

-

T/T or L/C

-

Size:

-

Custom Size

-

Usage:

-

Workshops Continual Conveying

-

Speed:

-

Adjsutable Speed

-

After-sales Service Provided:

-

Engineers guide production

-

Keyword:

-

Assembly Production Line

-

Belt material:

-

PVC PU Rubber

-

Production line type:

-

Automatic/Semi-automatic production line

Quick Details

-

Machinery Capacity:

-

1,000,000 shots

-

Weight:

-

5000 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

110/220/380V

-

Power:

-

2.2 KW

-

Key Machines:

-

Injection molding machine,mould,etc

-

Product name:

-

Washing Machine Assembly Line

-

Application:

-

Washine Machines

-

PAYMENT TERM:

-

T/T or L/C

-

Size:

-

Custom Size

-

Usage:

-

Workshops Continual Conveying

-

Speed:

-

Adjsutable Speed

-

After-sales Service Provided:

-

Engineers guide production

-

Keyword:

-

Assembly Production Line

-

Belt material:

-

PVC PU Rubber

-

Production line type:

-

Automatic/Semi-automatic production line

Our Products

19 years washing machine assembly line manufacturing experience

TIANTECH GROUP started to produce washing machine assembly line in 2003. Offering fully automatic assembly line and semi automatic assembly line. (including

twin tub washing machine assembly line, top loading washing machine assembly line, front loading washing machine assembly line, refrigerator & chest freezer assembly line

)

Now TIANTECH GROUP become washing machine factory package solution supplier, we not only supply washing machine moulds, washing machine spare parts, washing machine assembly line, but also arrange engineers to go overseas to train the local workers and help our overseas partner to establish their own quality control system, moreover, we also offer R&D service, to help our overseas partner to have the best designing for the market, currently we have many overseas projects such as in Iraq, Algeria , Uzbekistan, etc.

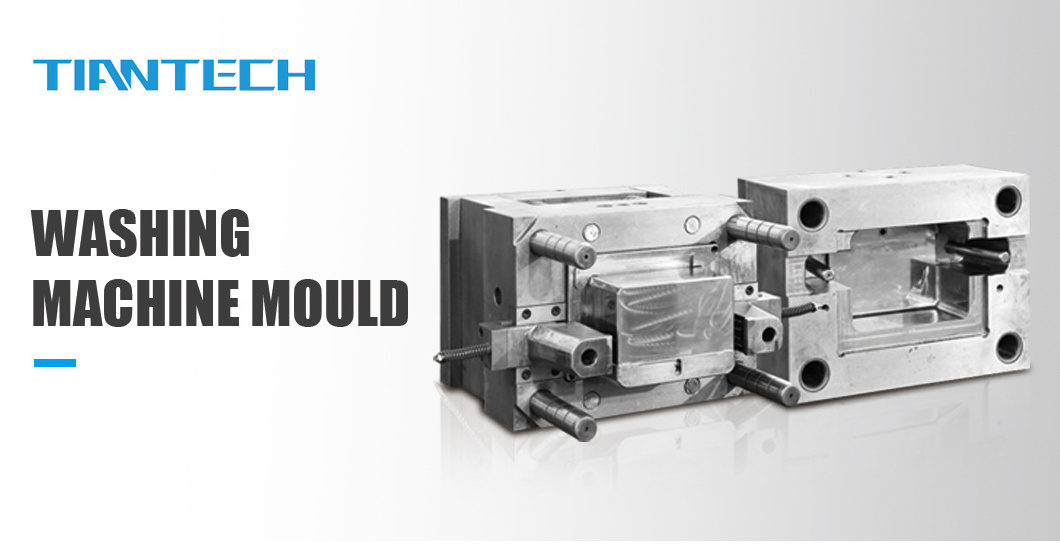

25 years experience of washing machine moulds manufacturing

Working with many washing machine factory in China and in the worlds, produce twin tub double layer, twin tub single layer, single tub, top loading and front loading washing machine moulds.

22 years washing machine spare parts manufacturing experience

TIANTECH GROUP started to produce metal parts such as brake disc, gear box, wash timers, washing machine motor in 2000, has more than more than 300 staff, 25 engineers, 8 modern assembly lines, 50 high precision injection molding machines. Daily output up to 120,000pcs of timers and 100,000pcs of gear boxes and 4,000,000pcs motors.

Specification

|

Name of Parts

|

Twin tub

|

Cabinet

|

Frame

|

Two way

|

Pulsator

|

|

Mould Dimension (mm)

|

1390*1070*1180

|

1410*1100*1210

|

1090*730*600

|

435*360*300

|

540*540*400

|

|

Plastic Parts Material

|

PP

|

PP

|

PP

|

PP

|

PP

|

|

Mould Material

|

Core-P20 Cavity- S55C

|

Core- S55C Cavity-P20

|

Core- S45C Cavity-P20

|

Core- P20 Cavity-P20

|

Core- S45C Cavity-P20

|

|

Moudle

|

One

|

One

|

One

|

Four

|

One

|

|

Clamp force

|

1800t

|

1800t

|

780t

|

200t

|

300t

|

|

Name of Parts

|

Wash&Spin Cover

|

Transparent Safety Cover

|

Control Panel

|

Water Stents

|

Filter Net

|

|

Mould Dimension (mm)

|

1180*695*560

|

460*420*320

|

1090*370*650

|

290*240*260

|

520*215*300

|

|

Plastic Parts Material

|

ABS

|

PP

|

ABS

|

PP

|

PP

|

|

Mould Material

|

Core-P20 Cavity- P20

|

Core-P20 Cavity- S55C

|

Core-P20 Cavity- SW718

|

Core-45# Cavity- 45#

|

Core-P20 Cavity- P20

|

|

Moudle

|

One

|

One

|

One

|

One

|

Two

|

|

Clamp force

|

1000t

|

250t

|

650t

|

86t

|

200t

|

Advantage:

1.We have more than 25 year washing machine moulds manufacturing experience, 22 years experience of producing washing machine spare parts and 20 years experience of produce washing machine.

2.Now we become washing machine factory package solution supplier.

3.We helped our Algeria, Iraq, Uzbekistan partners established their washing machine factory, etc.

4.We send engineers to overseas partners’factory to help them guide how to assembly washing machines and help them to establish quality control system.

5.We offer washing machine designing service according to our rich experience of producing washing machine moulds and washing machine.

Product Packaging

Hot Searches