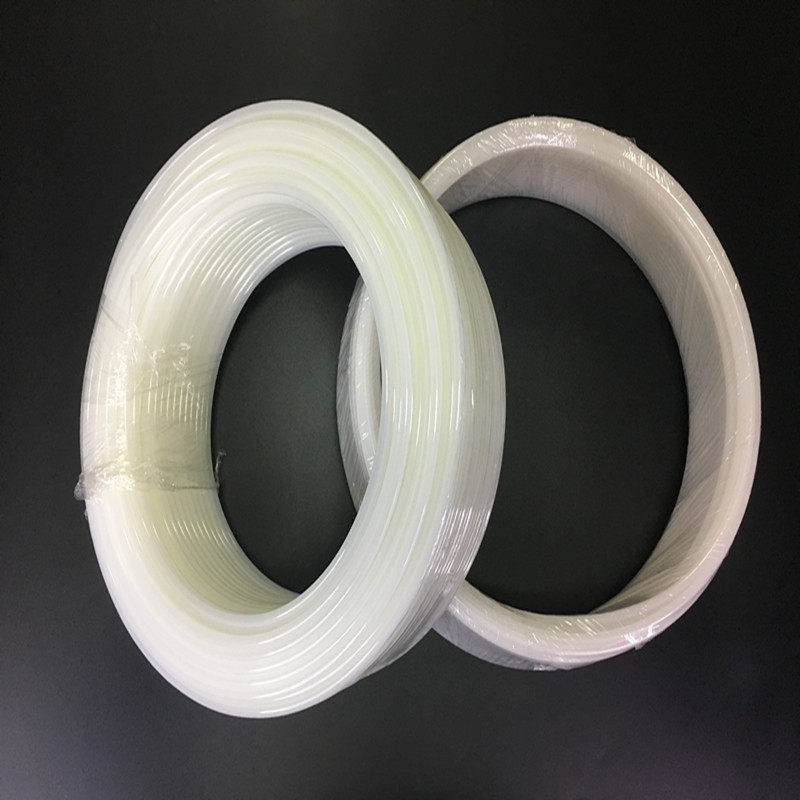

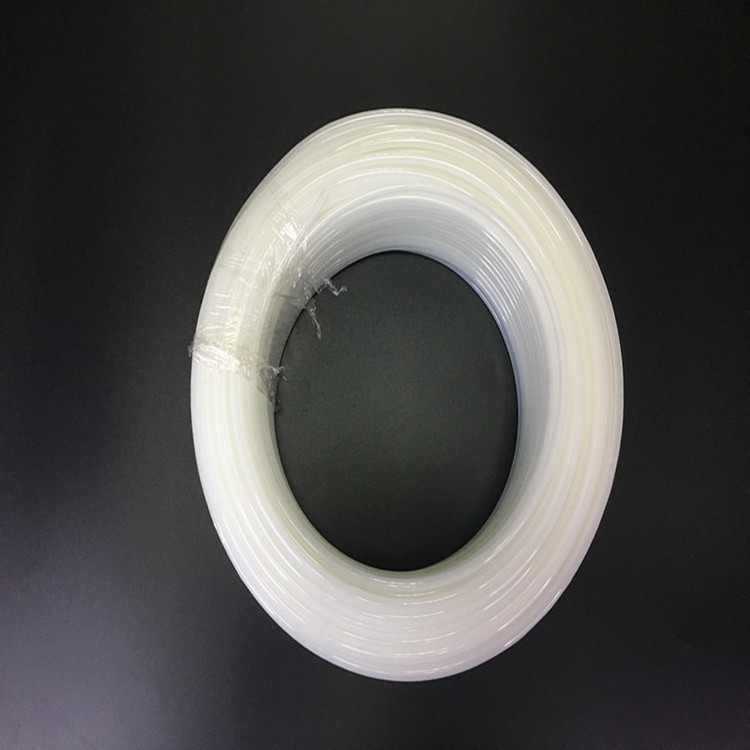

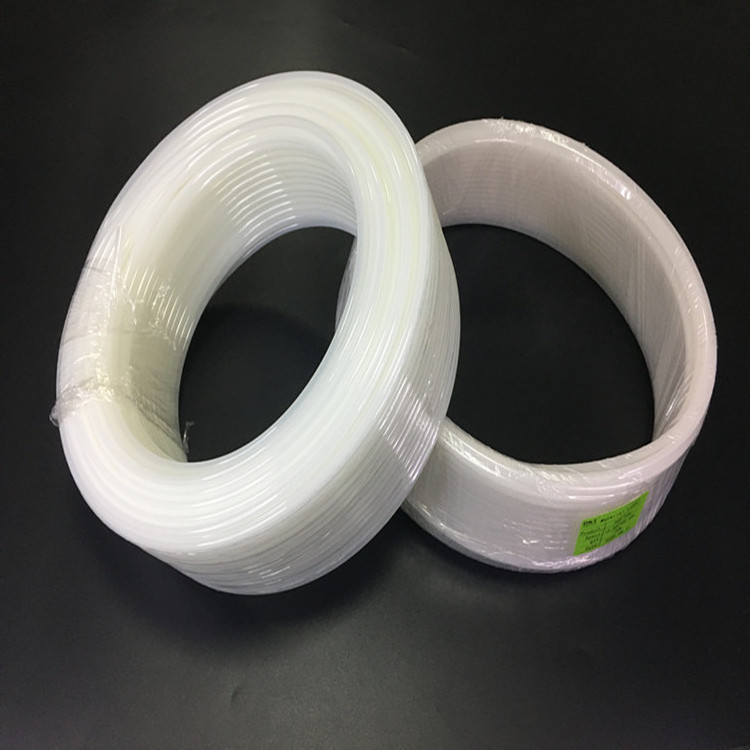

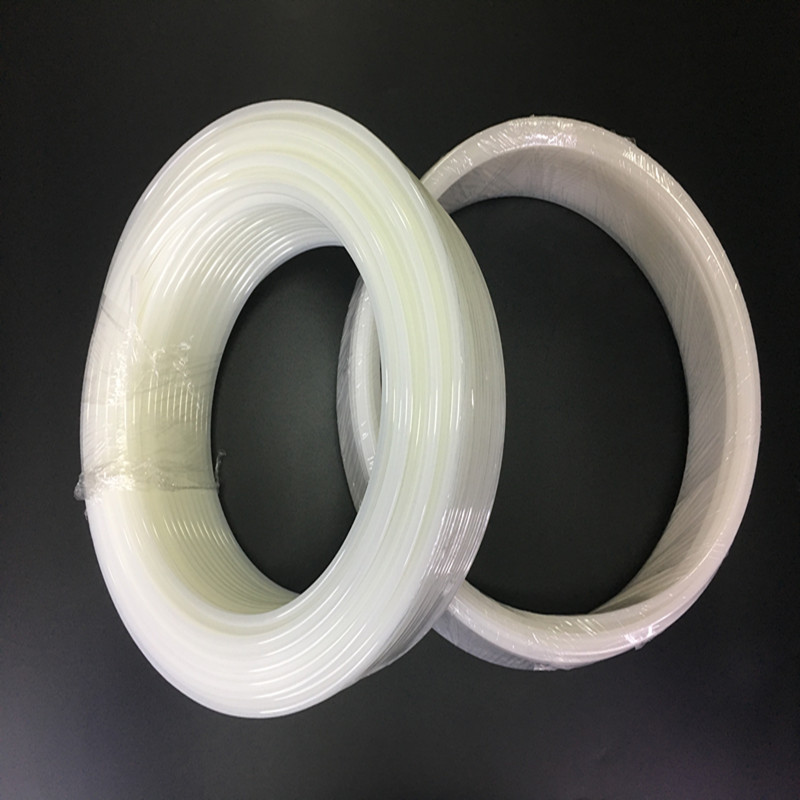

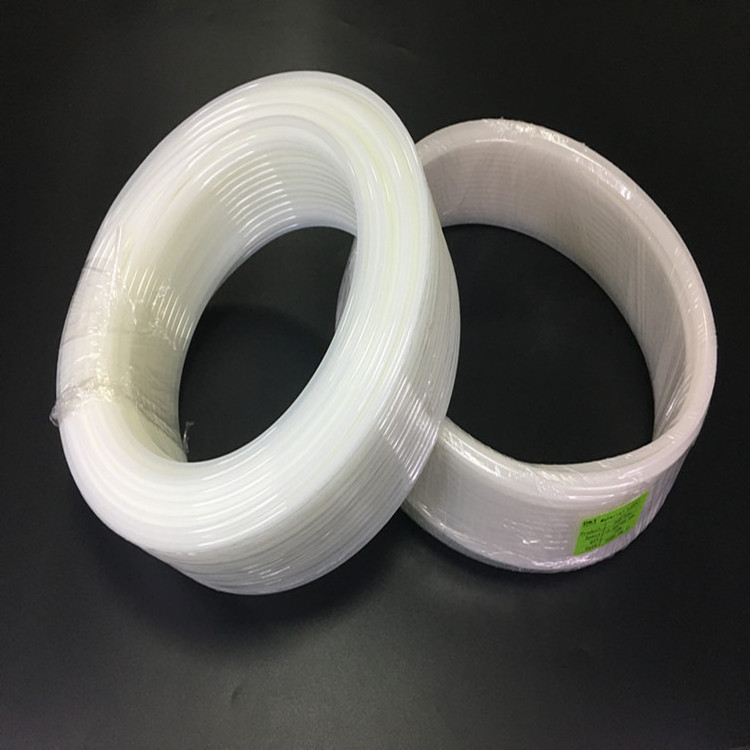

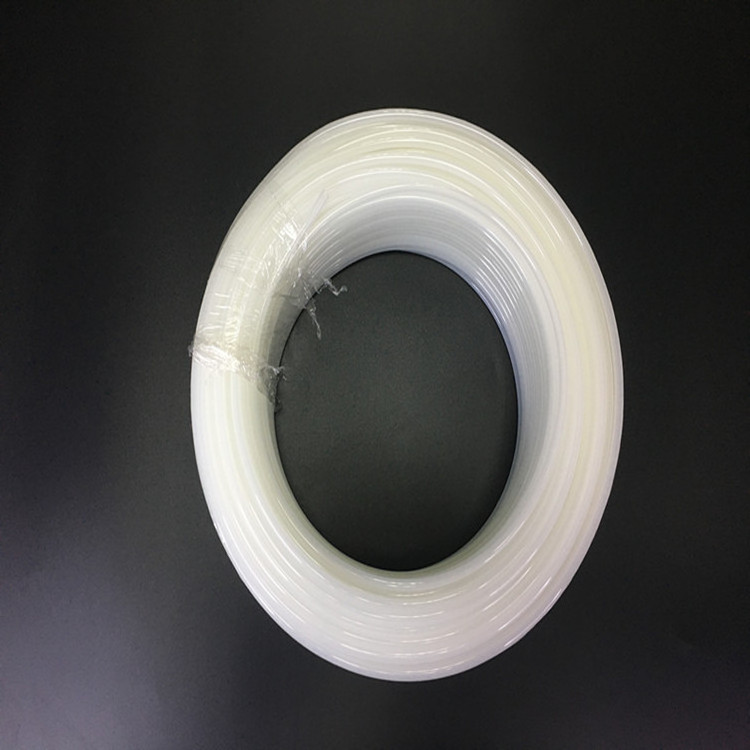

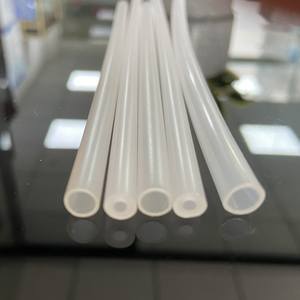

The application of fluoropolymer products is developing fast in recent years.

PTFE is well-known as " king of plastic".

As an alternative of traditional plastic, PTFE and other modified PTFE products are now widely used for their many advantages:

Non-stick;

Corrosion resistance;

Ozone and sunshine tolerance;

Thermal stability;

Fire resistance;

Physiological inertia

;

Electric insulation.

Here shows some main fields that PTFE products are widely used.

Chemical industry

Aerospace industry

Medical instruments

Electronic engineering

Semi-conduct industry

Mechanical industry