- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

up to the size

-

Size:

-

up to the size, Compact

-

Power:

-

up to request

-

Weight (KG):

-

65 kg

-

Brand origin:

-

Japan

-

Raw material:

-

SS304

-

Service life:

-

>15 years

-

Electrical components:

-

Schneider, Omron

-

Motor:

-

Sumitomo, Nissei

-

Application:

-

Activated Sludge Dewatering, especially for oily sludge

-

Certificate:

-

ISO 9000, CE

-

Operation:

-

Automatic

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BENENV

-

Material:

-

stain steel

-

Weight:

-

up to the size

-

Size:

-

up to the size, Compact

-

Power:

-

up to request

-

Weight (KG):

-

65 kg

-

Brand origin:

-

Japan

-

Raw material:

-

SS304

-

Service life:

-

>15 years

-

Electrical components:

-

Schneider, Omron

-

Motor:

-

Sumitomo, Nissei

-

Application:

-

Activated Sludge Dewatering, especially for oily sludge

-

Certificate:

-

ISO 9000, CE

-

Operation:

-

Automatic

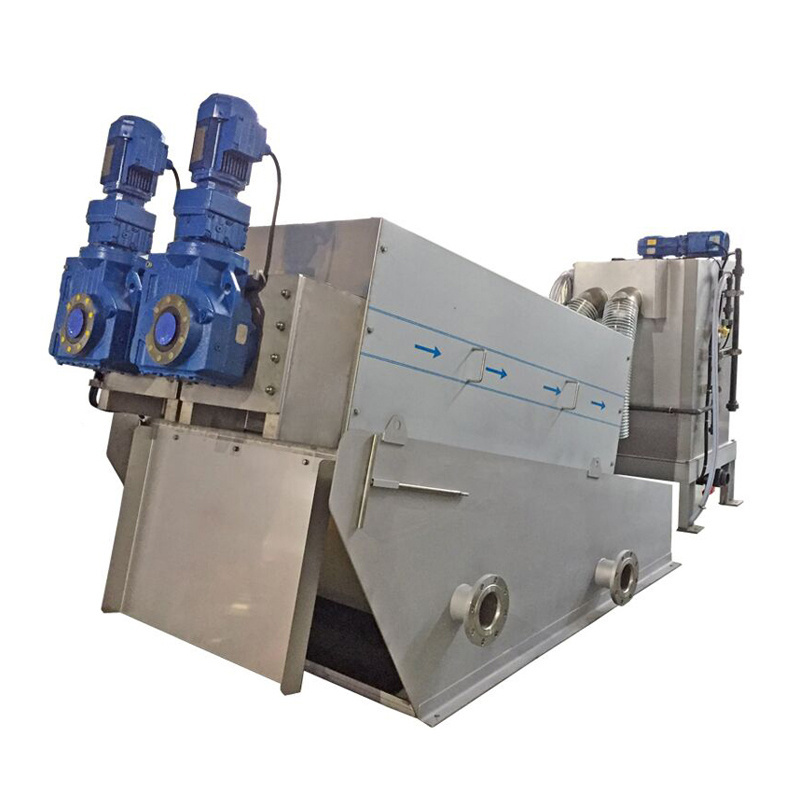

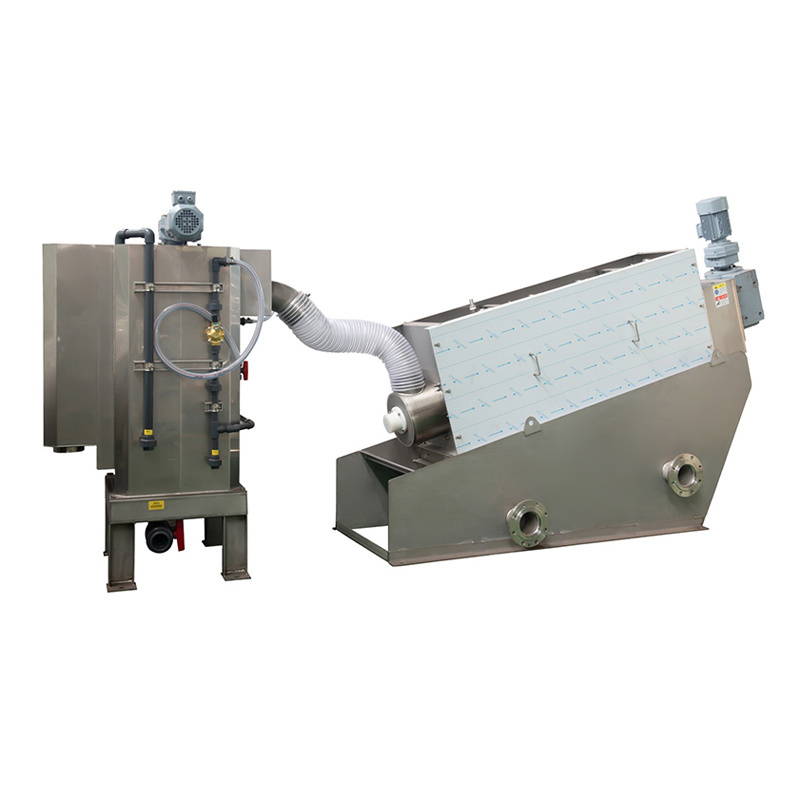

Multi-Disk Screw Press(Hereinafter referred to as MDS) belongs to the screw press, its clog-free feature and can

reduce the sedimentation tank and the sludge thickening tank, saving the investment costs of sewage treatment

plant construction and water consumption. The main units of MDS are the Screw and Fixed Rings and Moving

Rings. Mobilized by the screw, it continuously cleans the sludge out of the gaps, therefore, preventing clogging.

MDS also can operate automatically controlled by the PLC for 24 hours,unmanned. It's a new technology that

can replace the traditional filter press like belt press and frame press, the screw speed is very low, so it costs

low power and water consumption in contrast to the centrifuge, it is a cutting edge sludge dewatering machine.

| Japan Technology and Japan Quality | Vedio Support and Overseas construction |

| Fully-automatic control, continuous operation. | 2 Years ' Warranty |

| No cloging and Backwash | Stable Treatment Capacity |

| Large Transport Load | Easy Maintenance |

Q: Are you trading company or manufacture?

A: We are both manufacture and trading company. We have More than 30

years' professional experience as a

waste water treatment equipment manufacturer and engineering service enterprise.

Q : What are your main Products?

A: sludge dewatering machine equipment , sludge screw press, rotary drum screens ,sludge conveyor,

chemical dosing device , high-temperature vertical composting system, mobile dewatering system

and other solid waste treatment solutions.

Q. How Can I find the suitable model?

A: Please provide flow rate, solids content and sludge type, we can assist you in model selection.

Q: Where is your factory located?

A:

Yixing

City, which is very close to Shanghai with only less than 3 hours' driving.

Q: Do you provide OEM service?

A: Yes. Any required logos is available.

Q: How about the production capacity of your company?

A: Our factory covers area over 2

2

,000M

2

and produces machines 2000 sets per year.

Q: How could we trust you and your company? This is first time transaction?

A: Our company has more than 30 years professional experience. We cooperate over 1000 customers

in China and overseas. We export nearly 60 countries all over the world. Welcome to our company

and watch our plant production condition any time.

Q: What certificates do you have?

A: CE/ISO/SGS

Q: Do you offer after-sales service?

A: Yes. Engineers available.

Q: How long is your warranty?

A: 2 years after the arrival of the goods. During this period, as long as it is not a man-made

damage, we send the damaged parts free of charge.

Q: What about your delivery Time?

A: Normally within 45 days against down payment.

Q: What about the package of your export product?

A: We use anticorrosion wooden case with foam inside.

Q: What kind of payment do you accept?

A: T/T, L/C, PAYPAL, Cash, D/P, D/A, WESTERN UNIION, MONEYGRAM

Q: What kind of transportation do you offer?

A: Customers decide freight mode, Air, Land & Sea .