- Product Details

- {{item.text}}

Quick Details

-

Solution:

-

Stainless steel punching machine solution

-

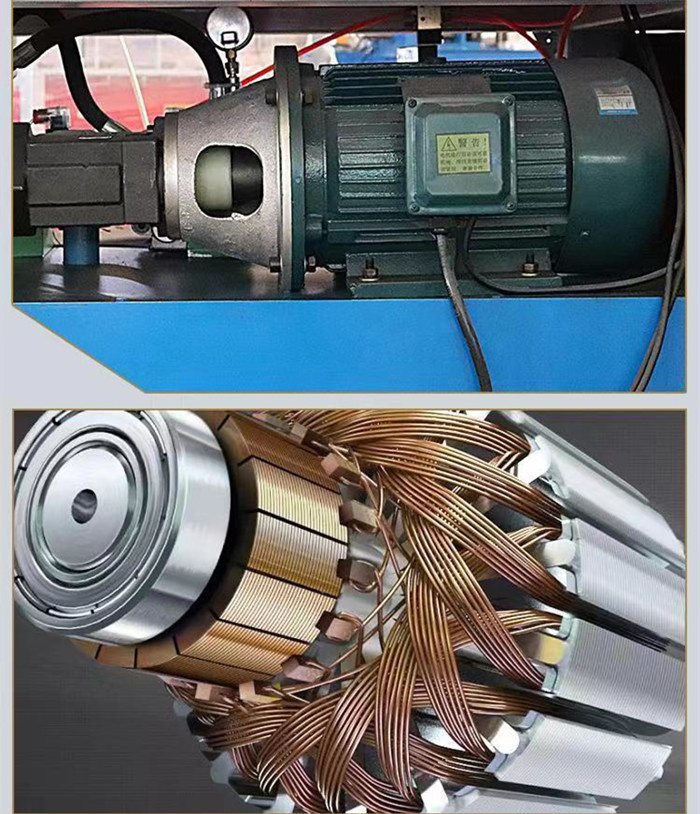

Servo motor:

-

0.75kw servo motor

-

Fuel tank size:

-

100*40*40mm

-

Mold:

-

According to the drawings or requirements

-

OEM/ODM:

-

Support various non-standard customization

-

Application:

-

Guardrail, anti-theft net, stair handrail, shelf, aluminum alloy

-

Software:

-

Permanently free to upgrade

-

Foot switch:

-

Standard with foot switch

-

Warranty:

-

Two-year warranty for the reducer

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

Elefine

-

Product name:

-

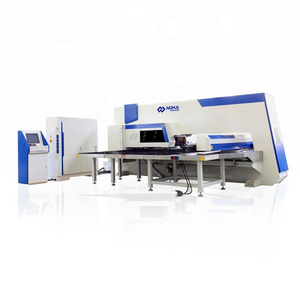

CNC high-speed hydraulic automatic punching system

-

Solution:

-

Stainless steel punching machine solution

-

Servo motor:

-

0.75kw servo motor

-

Fuel tank size:

-

100*40*40mm

-

Mold:

-

According to the drawings or requirements

-

OEM/ODM:

-

Support various non-standard customization

-

Application:

-

Guardrail, anti-theft net, stair handrail, shelf, aluminum alloy

-

Software:

-

Permanently free to upgrade

-

Foot switch:

-

Standard with foot switch

-

Warranty:

-

Two-year warranty for the reducer

Pipe profile processing technology CNC punch stainless steel pipe CNC special 6 meters hydraulic punching machine

Product Description

Specification

|

item

|

value

|

|

CNC or Not

|

CNC

|

|

Condition

|

New

|

|

Machine Type

|

Punching Machine

|

|

Slide Stroke (mm)

|

6200

|

|

Power Source

|

Hydraulic

|

|

Voltage

|

380V

|

|

Dimension(L*W*H)

|

6200*1200*1600

|

|

Motor Power (kW)

|

7.5kw motor

|

|

Model Number

|

EF-CKJ1

|

|

Weight (T)

|

50

|

|

Key Selling Points

|

High-accuracy

|

|

Warranty

|

3 Years

|

|

Applicable Industries

|

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Printing Shops, Construction works , Energy & Mining, Other

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Warranty of core components

|

24 months

|

|

Core Components

|

Pump, Gear, Motor, Gearbox, Pressure vessel, Engine

|

|

Servo motor

|

0.75kw

|

|

Solution

|

Stainless steel punching machine solution

|

|

Product name

|

CNC high-speed hydraulic automatic punching system

|

|

Fuel tank size

|

100*40*40mm

|

|

Mold

|

According to the drawings or requirements

|

|

OEM/ODM

|

Support various non-standard customization

|

|

Application

|

Guardrail, anti-theft net, stair handrail, shelf, aluminum alloy

|

|

Software

|

Permanently free to upgrade

|

|

Foot switch

|

Standard with foot switch

|

|

Warranty

|

Two-year warranty for the reducer

|

Advantages:

1. The increased width of the machine is 1 meter, which is relatively convenient to install the mold, and each part is equipped with reinforcing ribs

2. A sprayer is added to the position where the mold is installed on the workbench, which can cool the mold during work, making the life of the mold longer and more wear-resistant.

3. The diameter of the reducer is 90 to ensure that the mechanical stability is greatly improved

Design scheme of automatic punching system

The new CNC high-speed hydraulic automatic punching system (alias CNC punching machine) adopts the combination of the latest imported Taiwan machinery and low-voltage electronic technology, and can provide targeted solutions according to the different processing techniques of customers. It can realize one-time or two-time molding under the process requirements of a profile (pipe, profile) with multiple pass types that need to be processed. Through the design of the machine and mold structure, the stability and accuracy of the processing quality can be realized.

Overall structure of the machine:

The total length of the bed is 7.2 meters (to ensure that the workpiece processing length is 6 meters). The bed is assembled and welded with square tubes and iron plates. After annealing, it is processed with Italian large-scale gantry CNC machining centers. All machine plates and gantry steel plates are used Material welding combination of 45# steel carbon plate. The left and right supporting plates of the upper and lower plates of the workbench are 40MM thick, and a number of reinforcing ribs are added at the bottom for auxiliary load-bearing. And all the load-bearing support plates and upper steel plates are welded after CNC machining and tapping the upper 12.9 screws, which can ensure that the gantry frame will not deform when punching thick materials and the machine will be more stable. The wide gantry machine is more convenient for customers to install molds.

Machine accuracy requirements:

Each machine is equipped with Italian CNC large-scale gantry milling and milling from the beginning to the end. All the screw holes are tapped, the position of the installation accessories and the L-shaped groove for the installation of the linear rack are all precisely milled at one time to ensure the installation. The three-point-one-line balance of the rack and linear slide rail can be guaranteed to be within 0.05C from the beginning to the end. (The role of the L-shaped groove is to install 3 parts 2 of the rack into the L-shaped groove to ensure that the transmission gear of the machine can work back and forth on the linear rack for a long time without deformation of the rack)

Operating system:

The system program is that our technicians write the control program and install the electrical accessories. Each line is coded and marked, and the main controller PLC and precise feeding servo are all well-known brands in Taiwan. What's more important is that when customers have after-sales problems with electrical circuits during actual use, we can see all the fault information of the machine on the operation screen, directly determine the problem, and solve the problem for customers in a timely and easy manner. There is a remaining 7MM position at the clamping tube at the end of the workpiece, and program punching can be designed anywhere else (specify where to punch where), the hole distance accuracy is plus or minus 0.25MM, and there is no cumulative tolerance. The operation is simple and easy to learn (it is as simple as half an hour to learn to use the operation interface), the program is intelligent and humanized, programming can be performed without a calculator, the length of the remaining material can be automatically calculated, there is an error prompt for the wrong program, and the internal protection of the program is complete, preventing misuse It will not damage the machine, and the mold is easy to replace. The sensor adopts Taiwanese brand, and all low-voltage electrical appliances use Schneider brand.

Direct selling slide rail:

We use TBR40 linear slide rails, and install two slider guide rails on the same plane to ensure the parallelism of the reference side. The motion precision of the linear guide is high, and the diameter of the slide rail is one of the key factors determining its load size. In terms of performance and stability, the precision and quality of the TBR40 linear guide is better. It can ensure that there will be no problems when working for a long time.

Rack:

Our company adopts export cost-effective, high-precision racks, and the precision standards reach DIN5, ISO5, and GB4. Competitors basically use 8-9 standard racks. To put it simply, a small modulus is more precise than a large modulus, because if the diameter is constant, the smaller the modulus, the more teeth, and the higher the overlap coefficient (the more teeth meshing at the same time); however, the modulus Generally speaking, the number only represents the specification of its tooth shape, while the standard is the soul of its quality. Because the position where the rack is installed, the gantry mills through the installation position of the L-shaped groove to ensure that the rack will not be deformed.

Speed:

60-100 strokes per minute, adjustable speed, at least 1500 stainless steel pipes can be punched a day

Applications:

Wide range of application scenarios

Guardrail, anti-theft net, stair handrail, shelf, aluminum alloy, iron pipe

Packing & Delivery

Wooden package for

Pipe profile processing technology CNC punch stainless steel pipe CNC special 6 meters hydraulic punching machine

We Elefine warmly welcome you contact for OEM/ODM, we can do personalized customization for you.

Hot Searches