- Product Details

- {{item.text}}

Quick Details

-

Productivity:

-

12M³/H

-

Place of Origin:

-

shanghai

-

Brand Name:

-

hongang-kw15

-

Weight:

-

400 kg

-

Dimension(L*W*H):

-

1200*600*1500mm

-

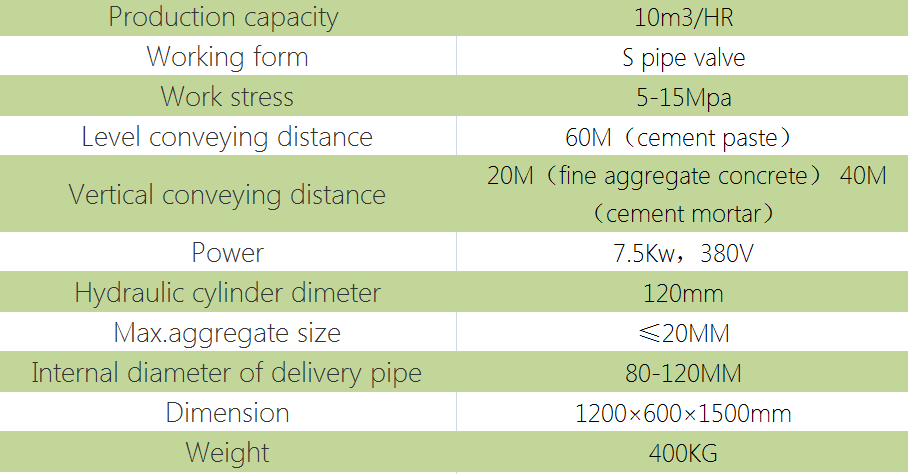

Production capacity:

-

12m3/HR

-

Product name:

-

diesel concrete deliver pump

-

Working pressure:

-

3Mpa

-

Horizontal conveying distance:

-

60m (cement slurry)

-

Vertical conveying distance:

-

20m (fine stone concrete)

-

Main motor power:

-

7.5kw, 380V (220V)

-

Screw rotation speed:

-

200-600RPM

-

W/C:

-

0.30 or higher

-

Notice:

-

diesel machine's details need to be customized

-

Maximum aggregate particle size:

-

≤30MM

Quick Details

-

Power Type:

-

Diesel

-

Max. vertical conveying distance:

-

30m

-

Max. horizontal conveying distance:

-

60m

-

Productivity:

-

12M³/H

-

Place of Origin:

-

shanghai

-

Brand Name:

-

hongang-kw15

-

Weight:

-

400 kg

-

Dimension(L*W*H):

-

1200*600*1500mm

-

Production capacity:

-

12m3/HR

-

Product name:

-

diesel concrete deliver pump

-

Working pressure:

-

3Mpa

-

Horizontal conveying distance:

-

60m (cement slurry)

-

Vertical conveying distance:

-

20m (fine stone concrete)

-

Main motor power:

-

7.5kw, 380V (220V)

-

Screw rotation speed:

-

200-600RPM

-

W/C:

-

0.30 or higher

-

Notice:

-

diesel machine's details need to be customized

-

Maximum aggregate particle size:

-

≤30MM

Title goes here.

-

Advantages

-

1. Full mechanical structure no matter maintenance or operation is 10 minutes single (foolproof operation) to break the hydraulic workers dare not touch will not operate the problem

2. Low maintenance cost;

3. Mobility is very convenient for a person to move; (before the hydraulic type needed 4-5 more people to move)

4. The power of the whole machine is only 11KW, which is very convenient for wiring in each floor; (hydraulic power 18-25kw wiring is very inconvenient)

5. The whole machine is so small that you can enter any small place; (before, the hydraulic type was too big to enter and exit in many places)

6. The machine adopts the modular design and can be assembled at any time.

7. The conveying height can be freely adjusted from 1-8 meters;

8. Affordable price can be better than ten times the labor, for the boss to save huge assets of small secondary structure pouring column pump truck, specially solve the problem of secondary structure construction cost, labor, low production efficiency. This machine is small in size, simple in operation, it can reduce labor intensity, it can be constructed in floor flexibly, and it can be cast near lintel and pillar reliably.

Operation procedure of small secondary constructional column pump

1. Check the appearance of the machine, whether the machine is damaged due to long-distance transportation, especially whether the electrical appliances and wires in the electrical box fall off.

2. Power on, the equipment shell shall be grounded. Start the motor to see if it works properly.

3. At the beginning of use, wet the pipe with dilute ash to drain the remaining ash in the pipe, and then clean the hopper and ash pipe.

Attention

1. If the wring cage is often stuck, it is generally loose slot belt, and should be adjusted to the degree of tension.

2. The power supply must be reliably grounded and have leakage protection device. When ash is struck, please pay attention to that the electric box should not be doused with water or operated with wet hands.

3. When the wring cage is stuck, start the reverse and then start the forward operation.

4. Pay attention to the two universal bearings not to be coated with dust. Add butter to the bearings every week.

5. The height of ash beating can be adjusted by random fitting, which should be installed at the bell mouth connection

Packaging: wooden case for machine or as customer's requirements.

Shipping: within 3 days after received the deposit for machine.

Pre-sale Service

1. Supply item design, process design.

2. Help you to chose the fit machine.

3. Making the machine according to your requirement.

Sale Service

1. Acceptance equipment together with you.

2. Help you to make the method statement and the details of the process .

After Service

1. Guarantee for a year.

2. Quality problem, we will send you the accessories.

3. Free repair whole using life(without the freight and accessories charge).

Shanghai Hongang Machinery Manufacturing Co., Ltd is a new branch of Shandong Jining Qingke Machinery Co., Ltd. Our new company is located in SHANGHAI,CHINA.

Our new company is established in July 29, 2015, registered capital of 5 million.

We are a manufacturer and specialize in this market for 10 years.

Our own factory is located in Jining city, SHANDONG province. We have CNC machining center, CNC

lathe, boring machine, and milling machine.

Main products: GQ60 reinforcing steel bar shearing machine , Bending machines, Straightening machines, Steel arc bending machine, Ground polishing machines, Terrazzo machines, Solar water pump, Garden Machinery(including tree spade & lawn mower), Construction machinery and accessories, Road marking and Mining equipment, Mining tools and so on.

We have passed the ISO9001:2000 certification. Our products have been exported to Europe, Russia, south America, Africa & the Middle East, more than 20 countries. We sincerely hope to have the opportunity to co-operate with you.

Our Factory

Our Partner

Our Group

1)Are you manufacture?

Yes. We are one of leading manufacturers

2)Do you have Stock productions to sell?

Yes, of course. But we also offer OEM service. Please send us some drawing.

3)What information do you want to know if i want to get a quotation?

a). The model/size of your products.

b). The application for your products.

c). Special package methods if you needs.

d). Raw material.

4)Do you inspect the finished products?

Yes.Each step of products will be carried out inspection by QC department until shipping

5)What advantages do you have?

(1) Punctual: Have your orders met with the latest delivery?

We are a manufacturer with so many advanced and new machines.

It ensures we have the ability to carry out the production schedual for punctual delivery.

(2) 20year production experience. We have over 20 years exprerience in this industry.

That means we can preview the problems for the orders and production.

Therefore, it will make sure to deduce the risk of bad situation to happen.

(3) Point to point service.

Are you manufacture?

Yes. We are one of leading manufacturers

6)Do you have Stock productions to sell?

Yes, of course. But we also offer OEM service. Please send us some drawing.

7)What information do you want to know if i want to get a quotation?

a). The model/size of your products.

b). The application for your products.

c). Special package methods if you needs.

d). Raw material.

8)Do you inspect the finished products?

Yes.Each step of products will be carried out inspection by QC department until shipping

9)What advantages do you have?

(1) Punctual: Have your orders met with the latest delivery?

We are a manufacturer with so many advanced and new machines.

It ensures we have the ability to carry out the production schedual for punctual delivery.

(2) 20year production experience. We have over 20 years exprerience in this industry.

That means we can preview the problems for the orders and production.

Therefore, it will make sure to deduce the risk of bad situation to happen.

(3) Point to point service.