- Product Details

- {{item.text}}

Quick Details

-

Power:

-

78.3kw

-

Dimension(L*W*H):

-

customized

-

Product name:

-

Steel Pipe Shot Blasting Machine

-

Dimension of inlet opening:

-

1200*400mm

-

Length of cleaning piece:

-

1200-12000mm

-

Roller speed:

-

0.5-4 m/min

-

Thickness of cleaning steel plate:

-

3-60mm

-

Motor brand:

-

Famous International Brand

-

Abrator:

-

blast wheel

-

Abrasive flow rate:

-

4*250 kg/min

-

The effective cleaning width:

-

800-3000mm

-

Transportation speed:

-

0.5-4m/min

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

XKMT

-

Weight (KG):

-

20000 KG

-

Power:

-

78.3kw

-

Dimension(L*W*H):

-

customized

-

Product name:

-

Steel Pipe Shot Blasting Machine

-

Dimension of inlet opening:

-

1200*400mm

-

Length of cleaning piece:

-

1200-12000mm

-

Roller speed:

-

0.5-4 m/min

-

Thickness of cleaning steel plate:

-

3-60mm

-

Motor brand:

-

Famous International Brand

-

Abrator:

-

blast wheel

-

Abrasive flow rate:

-

4*250 kg/min

-

The effective cleaning width:

-

800-3000mm

-

Transportation speed:

-

0.5-4m/min

30+ YEARS EXPERIENCE

High Performance

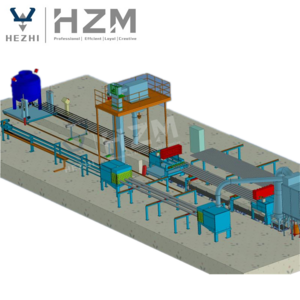

Steel Pipe Outernal Shot Blasting Machine

Name:

Steel Pipe Outernal Shot Blasting Machine

Model: XKQGW Series - Customized

Products Description

H beam structural steel cleaning roller conveyor type shot blast machines are designed as an optimal processing solution for steel plate/sheet metal, steel profile/beam/sections(H-beam, I beam, C-beam), steel pipes/tubes and steel structural framing, deformed steel bar etc, with residue from the shot’s abrasive action handled via a blowing and brushing system that ensures every last trace is removed.

In addition to the standard version of the roller conveyor blast machine, Qingdao Xinke has produced the non-standard model, designed specifically for the customers' workpiece details.

We can design and manufacture different size of steel plate shot blasting machine according to customers’ requirement.

You can decide to add a roller conveyor shot blasting system to your automatic treatment lines, including preheating, painting/coating and feed and transfer equipment.

In addition to the standard version of the roller conveyor blast machine, Qingdao Xinke has produced the non-standard model, designed specifically for the customers' workpiece details.

We can design and manufacture different size of steel plate shot blasting machine according to customers’ requirement.

Professional Shot Blasting Machine Manufacturer

Product Paramenters

|

Model

|

Steel pipe cleaning scope

|

|

QGN10

|

40-100

|

|

QGN40

|

100-400

|

|

QGN60

|

100-600

|

|

QGW30

|

30-300

|

|

QGW14

|

300-1400

|

|

QGW25

|

300-2500

|

|

QGW30

|

300-3000

|

Above parameters are standard data.

We can design and manufacture all kinds of non-standard shot blasting machines according to customers' requirement.

We can design and manufacture all kinds of non-standard shot blasting machines according to customers' requirement.

Details Images

Steel Pipe Outernal Shot Blasting Machine at

Client's factory

Xinke Production Workshop

Quality Guarantee:

1. Our quality guarantee time is one year. 2. The exwork product is good quality and has stable performance.

3. Machine in the process of using, appear quality problem, after the user notice, give a written reply within 24 hours or send service personnel leaving the factory, and the fault does not exclude the service personnel do not leave the scene.

4. In guarantee time, if there is any problem happens to the machine by normal operation, not because of artificial damage,

supplier is responsible to change the broken parts without any charge, but the easily wear spare parts are not included.

5. The seller supplies spare parts for the machine they sold. The seller has a sufficient inventory warehouse.

1. Our quality guarantee time is one year. 2. The exwork product is good quality and has stable performance.

3. Machine in the process of using, appear quality problem, after the user notice, give a written reply within 24 hours or send service personnel leaving the factory, and the fault does not exclude the service personnel do not leave the scene.

4. In guarantee time, if there is any problem happens to the machine by normal operation, not because of artificial damage,

supplier is responsible to change the broken parts without any charge, but the easily wear spare parts are not included.

5. The seller supplies spare parts for the machine they sold. The seller has a sufficient inventory warehouse.

1.How many days do you need to produce this machine?

This is our standard machine and we have some in stock,can be delivered right now after your deposit.

2.What does your factory do regarding quality control?

We pay much more importance to quality from the very beginning to the end of production,Every machine will be fully assembled and carefully tested before shipment.

3.What's your machine quality guarantee?

Quality guarantee time is one year,We choose world famous brand components to keep our machine in perfect working condition.

4.Are you able to give installation and commissioning overseas?How long will it takes?

Yes,we supply overseas service, but customers needs to pay for the engineers fight tickets and hotel,food .Small machine usually takes about 20days.

Hot Searches