100t/24h

Complete set

maize flour milling machine

It is from A to Z, means from start to end. such as maize cleaning machines-dampering-degerminating-roller

milling-sifting-packing-control system.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/420V

-

Power:

-

323KW

-

Weight:

-

55000 KG

-

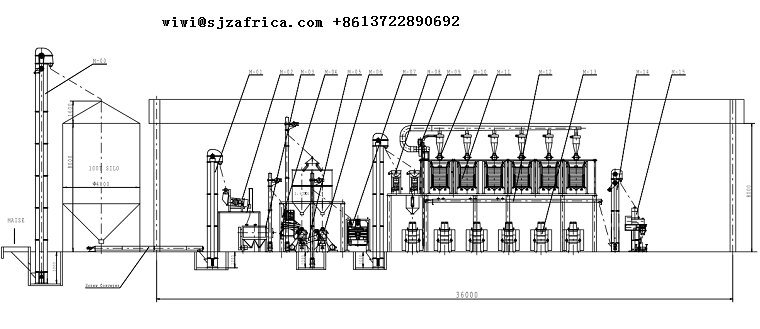

Dimension(L*W*H):

-

36*10*12M

-

Raw material:

-

Maize Corn

-

Maize milling machine pipes:

-

Stainless steel

-

Application:

-

Maize Corn Milling

-

Maize Milling degerminator:

-

Japan technology

-

Branch office:

-

Zambia,Uganda, Ethiopia

-

Maize Packing Section:

-

Auto packing machine

-

Installation:

-

Provide

-

Maize Sifting Section:

-

Double bin sifter

-

Capacity:

-

Process 100ton raw corn per 24hours

-

Control System:

-

Touch Screen Control

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HDF

-

Production Capacity:

-

100T/24H

-

Voltage:

-

380V/420V

-

Power:

-

323KW

-

Weight:

-

55000 KG

-

Dimension(L*W*H):

-

36*10*12M

-

Raw material:

-

Maize Corn

-

Maize milling machine pipes:

-

Stainless steel

-

Application:

-

Maize Corn Milling

-

Maize Milling degerminator:

-

Japan technology

-

Branch office:

-

Zambia,Uganda, Ethiopia

-

Maize Packing Section:

-

Auto packing machine

-

Installation:

-

Provide

-

Maize Sifting Section:

-

Double bin sifter

-

Capacity:

-

Process 100ton raw corn per 24hours

-

Control System:

-

Touch Screen Control

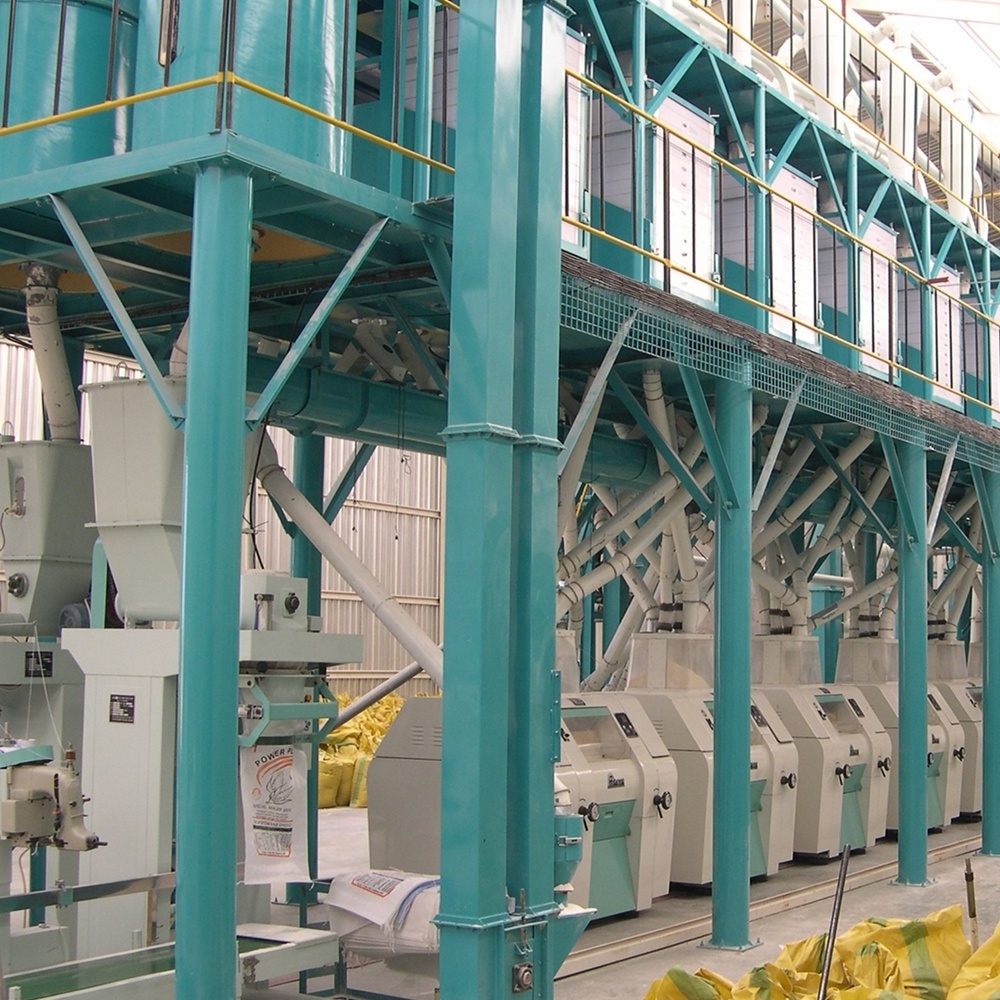

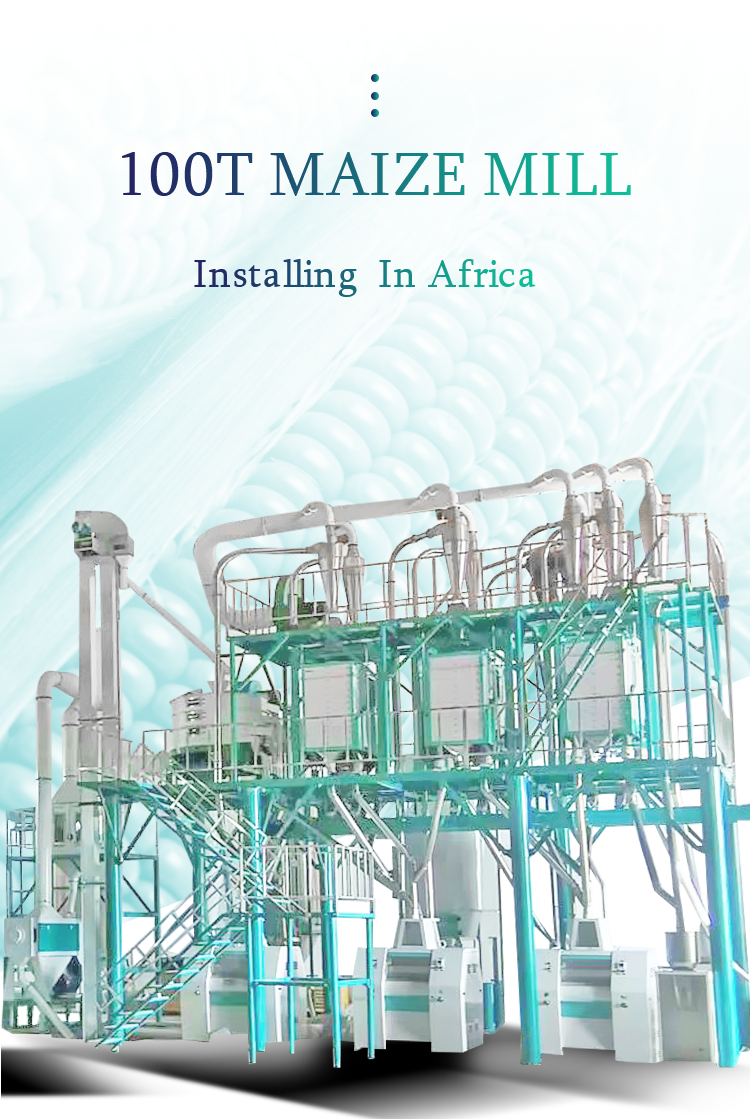

Product Description

100t/24h Complete Set Corn Flour Milling Machine For Sale

This

100t/24h Complete Set Corn Flour Milling Machine

is a complete line including cleaning to degerminating to milling to automatic packing and touch screen control systems. You can get the super white pure corn grits with different size from this automatic 100 ton/24h corn milling milling machine. Our machine can make different products from maize grain, like maize fine flour, maize grits and maize bran, maize germ, you can get different products to meet various need from the market.

Specification

|

Capacity

|

Process 100tons raw maize/corn per 24hours

|

|

|

|

|||

|

Final Product

|

Different sizes of maize flour, maize meal, maize grits, germ and bran

|

|

|

|

|||

|

Warehouse Size

|

36*10*12m (L*W*H)

|

|

|

|

|||

|

Container

|

4*40'

|

|

|

|

|||

|

Installation and commission

|

About 2 months

|

|

|

|

|||

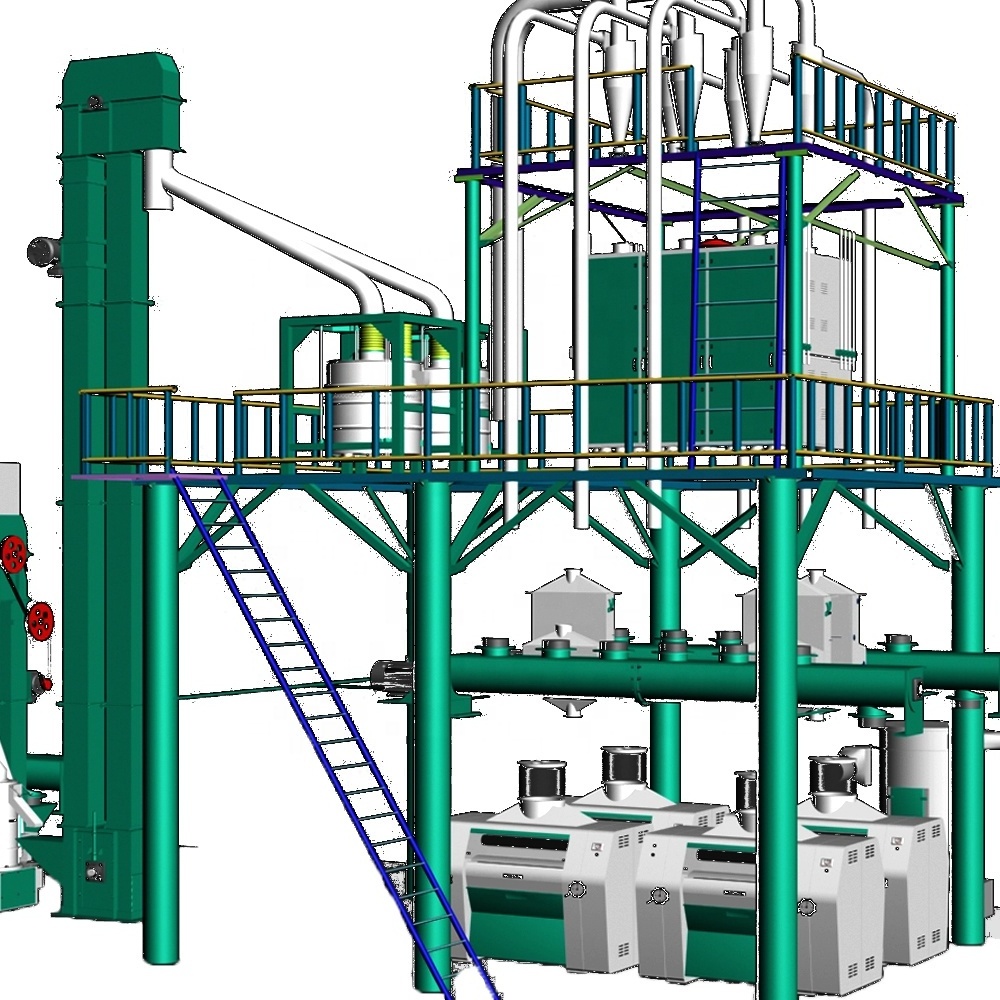

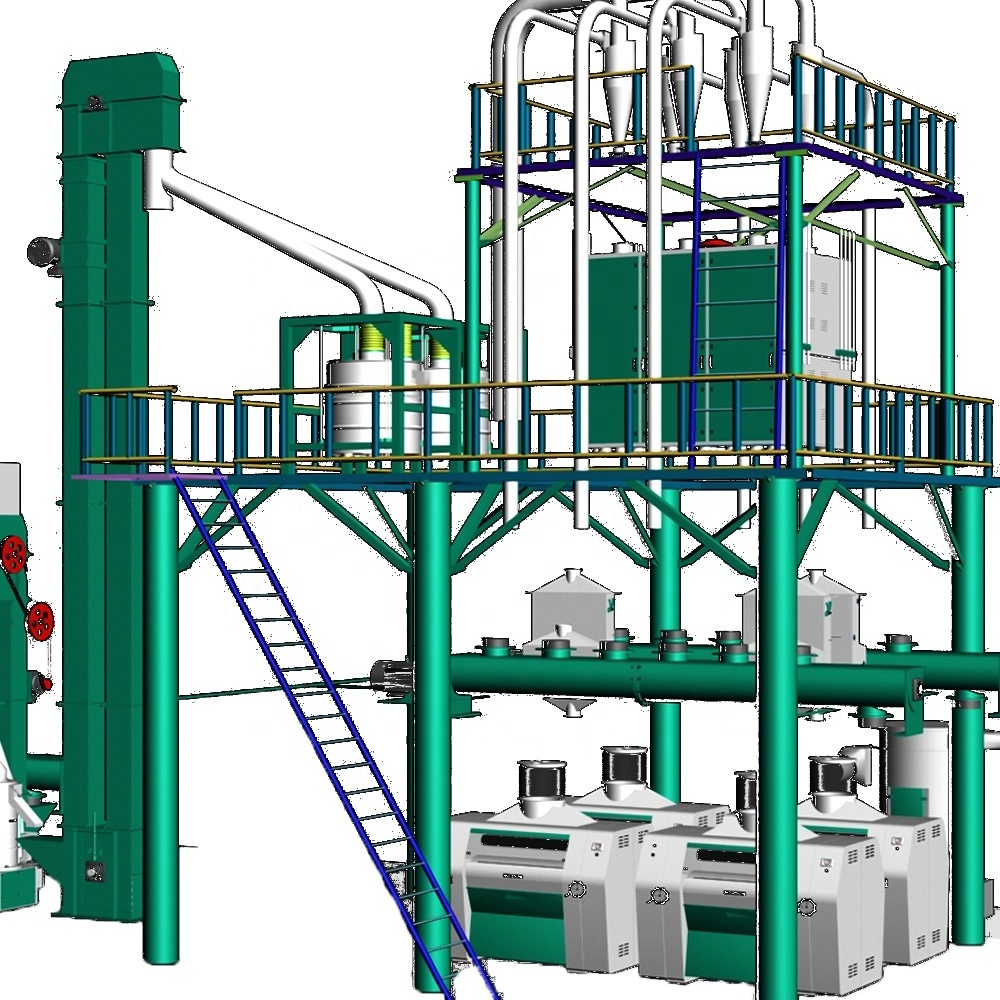

100t/24h

Complete Set

Corn Flour Milling Machine W

orkshop Building

Main Machine Details

Vibrating Sifter

The maize flows into the first sieve surface through feeding entrance. Inside this surface, large impurity on the upper sieve is discharged to the hopper. The maize through the first sieve surface to the second sieve surface for continual filter. The small

impurity is discharged on the soleplate straightly, the clean stock on the upper sieve surface come to the discharging hopper through the suction road.

impurity is discharged on the soleplate straightly, the clean stock on the upper sieve surface come to the discharging hopper through the suction road.

Destoner

Destoner is applied for efficient separation of stones and pebbles, glass, and other high-density matter from the stram of grain.

The destoner is also used to process rye, rice, and soybeans. High separating efficiency - excellent grain cleaning

The destoner is also used to process rye, rice, and soybeans. High separating efficiency - excellent grain cleaning

Moisture damper

The damper can add water to moisten the raw maize. Double layer damper, stainless steel one without rusty and working life is longer than the steel one. Two layers for moisturing much more efficiency.

Degerminator

Maize degerminator is applicable for taking the germ and bran out of the

maize, at the same time polishing the maize/maize gritz,get pure white /

yellow maize meal,maize grits,maize

samp, and is characteristic of high

volume of production, compact structure and convenient maintenance, thus making it an ideal equipment for

maize processing in the modern age.

maize, at the same time polishing the maize/maize gritz,get pure white /

yellow maize meal,maize grits,maize

samp, and is characteristic of high

volume of production, compact structure and convenient maintenance, thus making it an ideal equipment for

maize processing in the modern age.

Pneumatic roller mill

1)The partitioned paneling and swing-out feed module guarantee ideal access to the feeding and grinding rolls. This makes residue-free cleaning possible.

2) A pulse generator automatically adjust the feed material at the entrance door

Double section

Double sifter adopts the none-vertical axis and self-balance drive mechanism,It is manly used as the checker sifter for special flour to check the flour before packing.and can make a supplementary cleaning of powder material after being grinded.

Stainless Steel Pipe in the corn flour milling machine section the pipe is stainless steel. It is much more durable

Touch Screen Control is smart touch screen control, which is advance operation, and easily operation. and with a working history checking system. With fault alarm system.

Automatic packing section for corn flour milling machine. It can pack 5kg,10kg,20kg,50kg,100kg,200kg,etc woven bags. One worker can operate for filling, weighing, and sealing.

The Final Product of

Complete Set

Corn Flour Milling Machine

Our

complete set

corn flour milling machine can process both white maize and yellow maize, can produce super fine maize flour, refine maize flour, maize meal, maize grits, maize samp, semoule, etc, you can make Ugali, Sadza, Nshima,Fufu, Snacks food. The by-product maize germ can make oil, the maize bran can make animal feeds.

Click here to get more details.

After sales Service

1.Equipment Installation

Our professional technicians offer the guidance of installation, commissioning the corn flour maize flour milling machines,

2.Training Provide

Training workers which is helpful to guarantee the normal operation of the corn flour flour milling machine and to ensure the quality of finished products.

3.Fixing and Maintenance

If clients needs, our engineers can come to visit the site and give more advice face to face.

4.Spare Parts Supply

Available from Lusaka/Zambia Office timely where have put a big storage room and delivery door to door.

Our professional technicians offer the guidance of installation, commissioning the corn flour maize flour milling machines,

2.Training Provide

Training workers which is helpful to guarantee the normal operation of the corn flour flour milling machine and to ensure the quality of finished products.

3.Fixing and Maintenance

If clients needs, our engineers can come to visit the site and give more advice face to face.

4.Spare Parts Supply

Available from Lusaka/Zambia Office timely where have put a big storage room and delivery door to door.

Oversea Offices

We have three overseas offices: Ethiopia office, Zambia office and Uganda office. Engineers have been stationed overseas for a long time.so it is very convenient to provide Pre-sales consultation and after-sales service.

Certifications

This is our Hongdefa Certificate. We have Drum Sifter Patent,Degerminator Patent and Gravity Table Patent. And our

corn flour milling machine

and wheat flour mill machines have passed ISO SGS BV CE certifications.

Hot Searches