- Product Details

- {{item.text}}

Quick Details

-

Power:

-

80KW

-

Dimension(L*W*H):

-

Capacity Request

-

Weight:

-

200 KG

-

Application:

-

Brewpub

-

Product Name:

-

Beer Machine

-

Function:

-

Making Beer

-

Heating method:

-

Electric Heating Steam Heating

-

Thickness:

-

Inner 3mm External 2mm

-

Polishing:

-

0.4~0.6um

-

Material:

-

Stainless Steel 304/316

-

Control system:

-

PID

-

Color:

-

Silver

-

Package:

-

Wood Case

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

Zunhuang

-

Voltage:

-

380V

-

Power:

-

80KW

-

Dimension(L*W*H):

-

Capacity Request

-

Weight:

-

200 KG

-

Application:

-

Brewpub

-

Product Name:

-

Beer Machine

-

Function:

-

Making Beer

-

Heating method:

-

Electric Heating Steam Heating

-

Thickness:

-

Inner 3mm External 2mm

-

Polishing:

-

0.4~0.6um

-

Material:

-

Stainless Steel 304/316

-

Control system:

-

PID

-

Color:

-

Silver

-

Package:

-

Wood Case

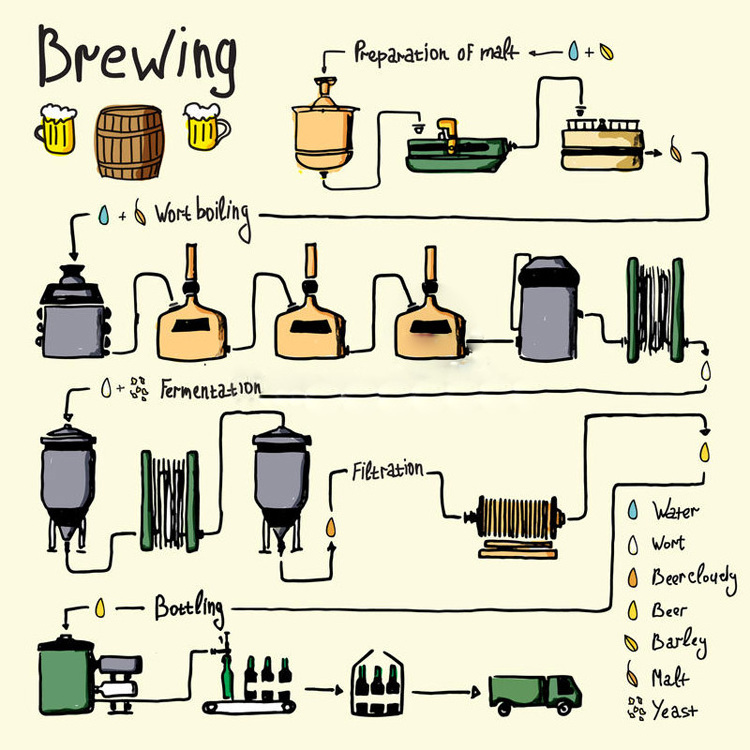

The whole beer equipment is consisted of Mash system,Fermentation system,Refrigeration system,Control system and CIP cleaning system. The tank of the system all adopts Red copper and S.S 304,and the system also have high automatic control capacity. brewery fermenter

Simple operation ,PLC automatic control system ,PLC semi-automatic control system.

At the same time if you have requirements, we could design and produce the products you need!

Beer Brewing Equipment

|

1 |

malt milling system |

malt miller machine grist case |

|

2 |

Mash system |

Mash tank/Boiling tank lauter tank

Whirlpool tank

|

|

3 |

Fermenting system |

Beer fermenters

|

|

4 |

Cooling system |

Ice water tank

|

|

5 |

CIP cleaning system |

disinfection tank & alkali tank &cleaning pump etc. |

|

6 |

Controller |

Control system, we have PLC automatic and semi-automatic, the brand include LG, Siemens and so on. |

|

7 |

Kegging system |

kegging system ( keg washer and keg filler machine), the control system brand is Siemens. |

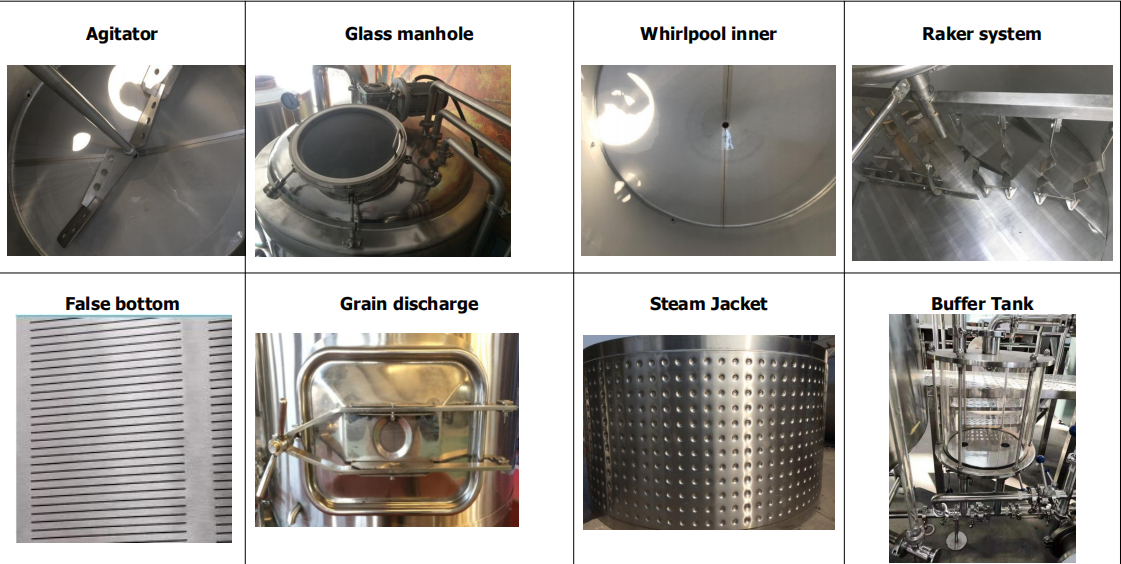

1. Mash system

Zunhuang series mash system consist of 1 vessel mash system, 2 vessels mash system, 3 vessels and other design, mainly includes mash tank, brew kettle, lauter tank and whirlpool.

Now Zunhuang equipment adopt electric heating, steam heating, gas heating and direct fire heating method on mash heating system. brewery tank

1000L 3 vessels

Brewhouse: Mash tun+ Lauter+ Brew kettle/ Whirlpool+HLT.

Material: SS304/SS316/SS316L/Red copper/Titanium plate/Other material.

Heating method: Electric heating/ Steam heating/ Direct fire heating.

For mash system, beside these main tanks also with other auxiliary equipment such as pump, plate heat exchanger, buffer tank, hop filter, platform, pipes and other necessary.

Support customization, please contact for more requirements!

2. Fermentation System

Zunhuang company are generally use 12 days as fermentation to configured fermentor,high quality fermentation, fermented good quality beer,the right amount of good commodity market with a bright future. conical beer fermenter

Tank date:

1. Capacity: 50L-30000L, 1bbl-100bbl, +25% Head space

2. Interior shell thickness 3-6mm, Exterior shell=2mm

3. 100% TIG welding with pure argon gas shield

4. Interior finish: pickled and passivated, external polished, 80mm insulated

5. Test pressure 3 bar, working pressure 1.5 bar

6. Glycol zones (Both on side and concial/bottom)

7. 60°conical bottom for Fermener, Shadow less side man way

8. Racking arm, Sample valve, Pressure relief valve on the top, Dry hopping on the top

9. Mechanical relief valve 3 bar on CIP arm with pressure gauge

10.Adjustable tank leveling pads conical beer fermenting tank

Details

3. Cooling System

Cooling system mainly includes Ice water tank, glycol water tank, plate heat exchanger, refrigeration unit, cooling pipelines and vales and control system.

4.CIP system brew beer kit

CIP cleaning system is consist of alkali tank, acid tank, sterilization water tank, disinfection tank, sanitary pump.

Accordingly the capacity of the equipment, Zunhuang company special manufactured small CIP cleaning trolley.

Complete beer production line:

1: 500L Home beer brew machine

2: 1000L Micro brewery equipment

3: 2000L Commercial beer production line

Beer fermenter:

1: 1000L High quality conical tank

1. Ocean shipment,railway shipment,express delivery.

2. No matter flat pack to save shipping cost,or fill with your merchandise into allassembled displays to ship together,all is up to you.

3. And we have our own department to arange the shipments.we ship worldwide dierctly by see,railway or express.we will provide all documents you need to import.

4. We packed the goods to meet the transport distance, shock, rust and anti-handling requirements damaged before shipping, to ensure the safe transport of goods to reach the buyer designated location before it is shipped.

Company service

Ten provide to service you:

1. After-sale Service for the whole life.

2. 24h service for you, solve your urgent problem first time.

3. 3 years warranty for the main products.

4. Free design for your brewery layout for 2D or 3D.

5. Spare parts replacement and repair service provided.

6. Engineer going abroad for installation, debugging and technical training if you need.

7. Provide the Form E, CO, etc..others necessary reduce import Tax files for you.

8. To provide update information about brewing equipment technology once we test.

9. Help you send the goods if you have others company order, then send to you together.

10. Door to Door service, if you need any brewing parts. conical fermenter 1000l