- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

400 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

DALI

-

Voltage:

-

380V or Customized

-

Dimension(L*W*H):

-

23000x2500x3500mm

-

Power (kW):

-

200

-

Weight:

-

20000 KG

-

Name:

-

DL-1200 PET Sheet Extusion Production line

-

Raw material:

-

PET

-

Processing Type:

-

Extrusion casting

-

Product name:

-

PET Sheet

-

Certification:

-

CE

-

Color:

-

Customized Color

-

Motor:

-

Siemens Beide

-

Inverter:

-

Dalta

-

Application Field:

-

Thermal forming,Printing,Metal/Food packaging etc.

-

After-sales Service Provided:

-

Service Machinery Overseas

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

40:1

-

Screw diameter (mm):

-

72

-

Screw Speed (rpm):

-

400 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

DALI

-

Voltage:

-

380V or Customized

-

Dimension(L*W*H):

-

23000x2500x3500mm

-

Power (kW):

-

200

-

Weight:

-

20000 KG

-

Name:

-

DL-1200 PET Sheet Extusion Production line

-

Raw material:

-

PET

-

Processing Type:

-

Extrusion casting

-

Product name:

-

PET Sheet

-

Certification:

-

CE

-

Color:

-

Customized Color

-

Motor:

-

Siemens Beide

-

Inverter:

-

Dalta

-

Application Field:

-

Thermal forming,Printing,Metal/Food packaging etc.

-

After-sales Service Provided:

-

Service Machinery Overseas

PRODUCTS DESCRIPTION

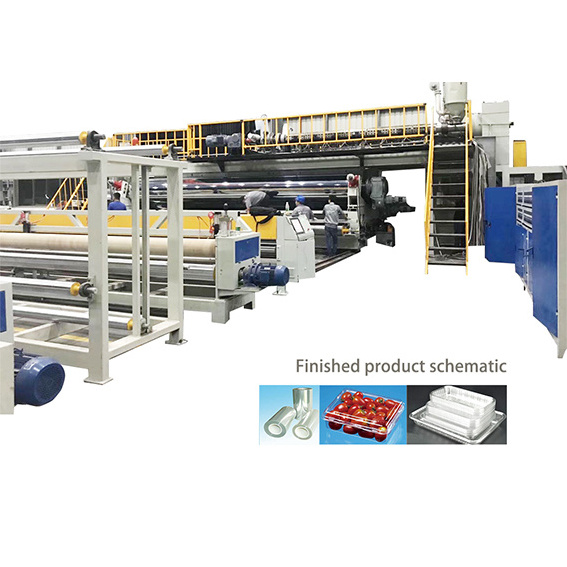

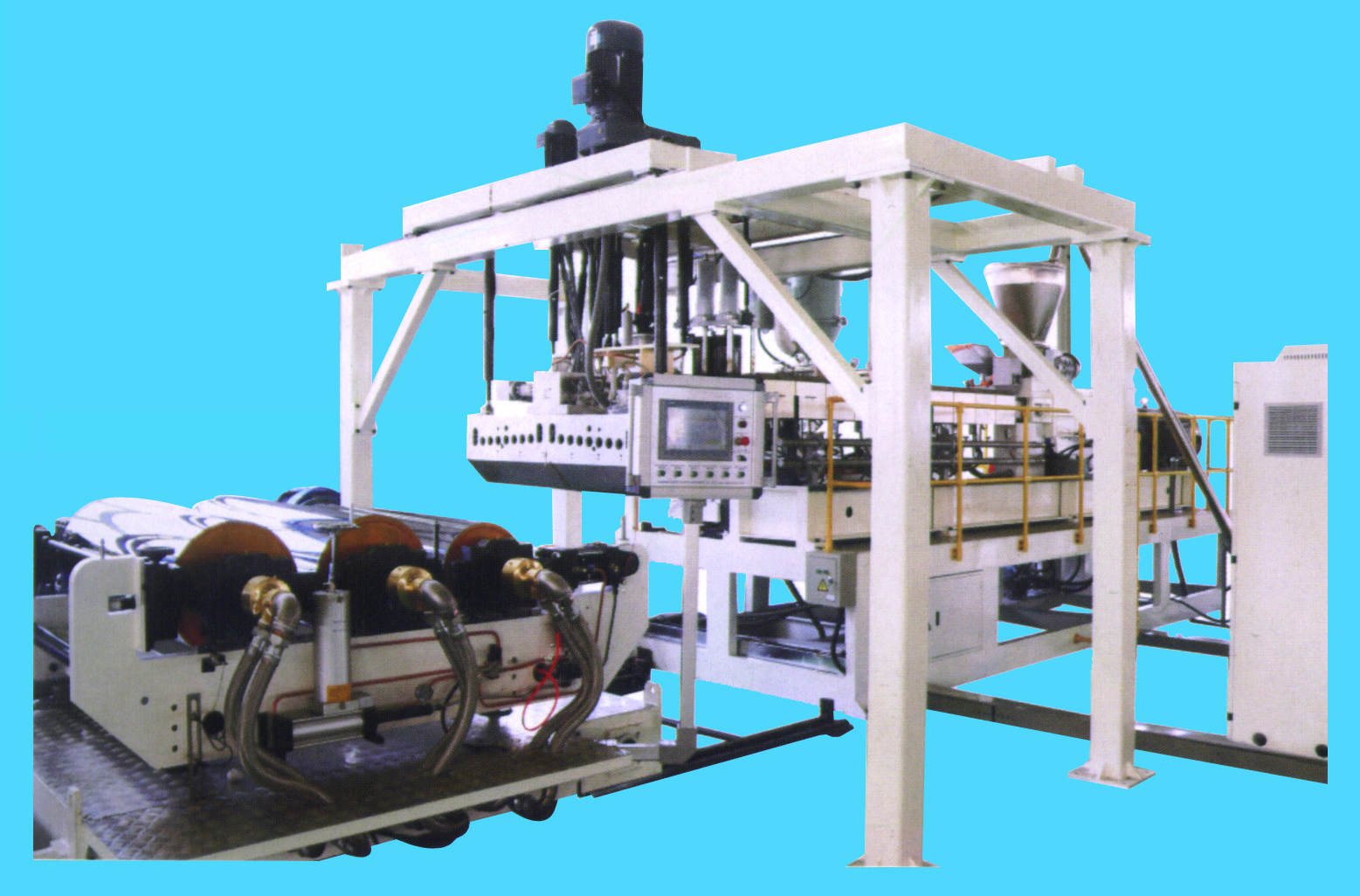

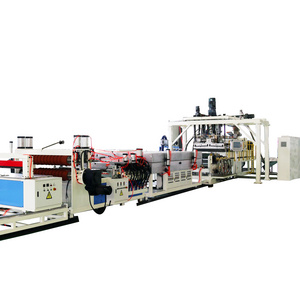

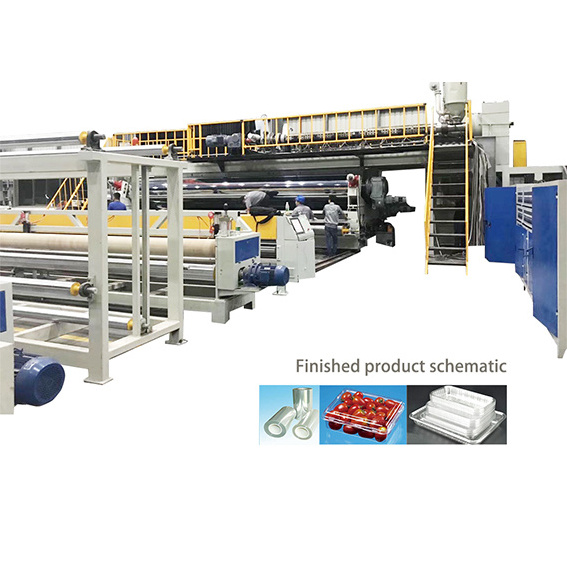

1200mm Double-Screw PET Sheet Extrusion Production Line

PET Sheet Production Line is divided into three types:Crystalline dried PET sheet production line single screw,twin-screw

vent-free crystal dried PET sheet production line,single screw exhaust-free,crystal dried PET sheet production line.Do

single,multi-layer sheet production line,multi-extruder co-extrusion.Processed materials can be processed APET,PETG,CPET etc..

vent-free crystal dried PET sheet production line,single screw exhaust-free,crystal dried PET sheet production line.Do

single,multi-layer sheet production line,multi-extruder co-extrusion.Processed materials can be processed APET,PETG,CPET etc..

All three devices can be single,multi-layer co-extruded sheet.

Using multiple extruders co-extrusion technology to produce multi-layer co-extruded composite PET,such as:APET/PETG,PETG/APET/PETG,APET/CPET/APET etc..

PET is used widely in plastic processing field such as food packaging materials because it has good transparency,neutral in taste,high impact resistance,easy to recycle and other excellent performance.

Using multiple extruders co-extrusion technology to produce multi-layer co-extruded composite PET,such as:APET/PETG,PETG/APET/PETG,APET/CPET/APET etc..

PET is used widely in plastic processing field such as food packaging materials because it has good transparency,neutral in taste,high impact resistance,easy to recycle and other excellent performance.

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Data

|

|

|

|

|

||||

|

1

|

Products

|

PET Sheet

|

|

|

|

|

||||

|

2

|

Thickness range(mm)

|

0.15-1.5mm

|

|

|

|

|

||||

|

3

|

T-die size(mm)

|

1200

|

2000

|

2300

|

2500

|

3000

|

||||

|

4

|

Max working width(mm)

|

1000

|

1700

|

2000

|

2200

|

2700

|

||||

|

5

|

Cooling Method

|

Circulating water cooling

|

|

|

|

|

||||

SALES AND SERVICE NETWORK

Our company, Changzhou New Dali Plastic Machinery Co., Ltd., is dedicated to providing high-quality plastic machinery to customers around the world. Our products have been sold in various countries and regions, and our service standards remain consistent across all locations. We strive to exceed our customers' expectations through continuous improvement and innovation. Trust us to fulfill your plastic machinery needs with exceptional products and world-class service.

COMPANY PROFILE

Changzhou New DaLi Plastics Machinery Co,.Ltd was founded in 2001, located in Changzhou City, Jiangsu Province (near Shanghai), covers an area of 10,000 square meters, is a company with more than 20 years of experience in the production of extrusion molding equipment. The company has more than 100 employees, more than 40 patents research and development.Through the last 20 years' efforts, New Dali has successfully produced and sold more than 1500 complete production lines, and part of them have been exported to the Europe&United States, Russia, Iran, Turkey、Malaysia、India and other foreign countries.

OUR CLIENT REPRESENTATIVES

QC PROFILE

Changzhou Dali Plastics Machinery Co.,Ltd has a team for technical support and service with professional skill, careful attitude and comprehensive knowledge; a guaranteed storage of spare parts; abundent experience of on site installation and commissioning, as well as training, which is capable of quick respond to customer regarding products consulting, order processing, installation and after-sale service etc..

OUR SERVICES

Pre-sale

We provide presales service in various forms, for example, making investment budget, manufacturing planning, etc. so that customers make a reasonable plan with less cost.

Investment budgeting---We provide services of product profit analysis, recommendation of machine and auxiliary equipment and relevant budgeting, human resources allocation and budgeting.

Plant Planning---We provide the mounting dimension of the equipment base, design of equipment layout, workshop ventilation, water transmission etc.

On-sale

Detailed design of workshop lay-out

Technological information of provided products

Schedule about design, manufacture and installation

Working & Producing process

Training courses for the technician team so that the installation is safe and standard

After-sale

For customers buying our products, we provide them training so that they can use and maintain the machine independently.

We will offer to customers technical support in time. If needed, we will offer on-line guidance and assistance.

We can provide free technical guidance if customers need new equipment, add or rebuild equipment.

We will prioritize the product upgrading of previous customers.

FAQ

Q1,What about your machine price?

A1,Anytime we will guarantee quality first, of course we can offer you reasonable and satisfied price!

Q2, What about the payment way?

A2, By TT, L/C at sight or Alibaba trade assurance. 30% down payment should be paid after contract is valid, 70% balance should be paid before shipment.

Q3, Installation and stuff training available from you?

A3, Yes, we can dispatch our rich experience engineers to your factory and train your workers. Also we can online guide your members.

Q4. How long is the guarantee?

A4. We offer you high quality machines with 12 months guarantee and reply you as soon as possible within 24 hours.

Q5. If the machine some parts is broken one day, how can we get help from you?

A5. We will send you spare parts free of charge if they are in warranty, not including easy-broken parts. For easy-broken parts, we will only charge cheap costs.

Q6.How does your factory do regarding quality control?

A6.We have passed the ISO9001:2000 Quality Management System and CE certificate and we have a special QC department in charge of products' quality. If you also need other certificates, we also can help to apply.

Q7. What is your packaging?

A7. Our conventional packaging is: Wrap the plastic film around the machine,and then put the machine in a wooden box.

Q8. How can we check the machines before delivery?

A8. We can provide online checking when testing the machine on site. We will take and prepare detailed testing videos for your checking before the delivery. We accept third-party testing. Except above points,we will provide detailed testing report.

A1,Anytime we will guarantee quality first, of course we can offer you reasonable and satisfied price!

Q2, What about the payment way?

A2, By TT, L/C at sight or Alibaba trade assurance. 30% down payment should be paid after contract is valid, 70% balance should be paid before shipment.

Q3, Installation and stuff training available from you?

A3, Yes, we can dispatch our rich experience engineers to your factory and train your workers. Also we can online guide your members.

Q4. How long is the guarantee?

A4. We offer you high quality machines with 12 months guarantee and reply you as soon as possible within 24 hours.

Q5. If the machine some parts is broken one day, how can we get help from you?

A5. We will send you spare parts free of charge if they are in warranty, not including easy-broken parts. For easy-broken parts, we will only charge cheap costs.

Q6.How does your factory do regarding quality control?

A6.We have passed the ISO9001:2000 Quality Management System and CE certificate and we have a special QC department in charge of products' quality. If you also need other certificates, we also can help to apply.

Q7. What is your packaging?

A7. Our conventional packaging is: Wrap the plastic film around the machine,and then put the machine in a wooden box.

Q8. How can we check the machines before delivery?

A8. We can provide online checking when testing the machine on site. We will take and prepare detailed testing videos for your checking before the delivery. We accept third-party testing. Except above points,we will provide detailed testing report.

Hot Searches