- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

950(L)x850(W)X1200(H)mm

-

Weight (T):

-

4 T

-

Power (kW):

-

60

-

Warranty:

-

1year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Weight:

-

3 tons

-

application:

-

tempeing ,heat treatment,drying,annealing,quenching,normalizing

-

fuel:

-

electric

-

rated temperature:

-

1100℃

-

The power of the fan:

-

0.75kw/set

-

Furnace temperature uniformity:

-

±5℃

-

Control accuracy:

-

0.1 grade

-

Heating up time:

-

≤2.5h

-

Color:

-

Customer Request

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Foxing

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

950(L)x850(W)X1200(H)mm

-

Weight (T):

-

4 T

-

Power (kW):

-

60

-

Warranty:

-

1year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Weight:

-

3 tons

-

application:

-

tempeing ,heat treatment,drying,annealing,quenching,normalizing

-

fuel:

-

electric

-

rated temperature:

-

1100℃

-

The power of the fan:

-

0.75kw/set

-

Furnace temperature uniformity:

-

±5℃

-

Control accuracy:

-

0.1 grade

-

Heating up time:

-

≤2.5h

-

Color:

-

Customer Request

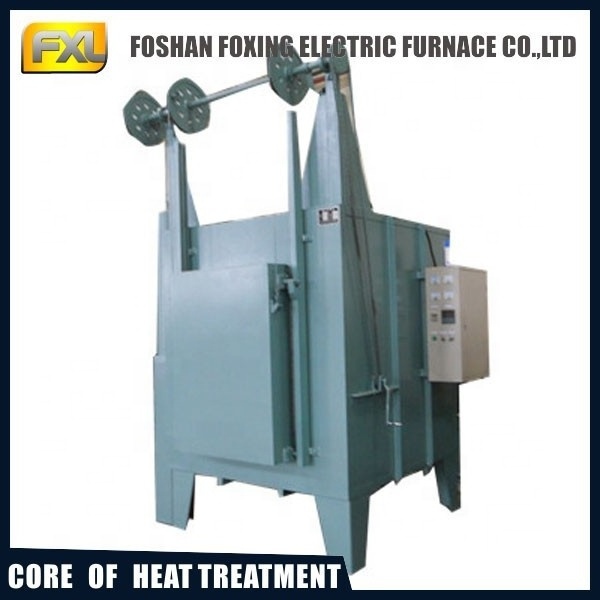

Chamber electric resistance furnace

1.Application

This type oven a cycle working type furnace which is used for general metal heating treatment, harening and tempering, drying.

2. technical parameter

A. rated power:40kw

B. The effective working size:950(L)x850(W)X1200(H)mm

C. Rated voltage:380V/3phase

D. Frequency:50HZ

E. Reted temperature:1100℃

F. Heating type : electric

G. Heating element connection :Y

H. Heating zone:one zone

I. Temperature control:Master temperature control solid-state relay is controlled by digital display instrument

J. Oven door open way: Manual door open

K. The power of the fan :0.75kw/set

L. Furnace temperature uniformity :±5℃

M. Surface temperature:≤50

N. Control accuracy:0.1 grade

O. Heating up time:≤2.5h

3. Construction

This equipment consists of furnace body (including furnace chamber), the oven door and open mechanism, heating element, electrical control system and other parts.

Application:It is the special heat treatment equipment mainly used in steel workpieces, metal parts quenching, normalizing, annealing and other conventional treatment .

structural features:

1. Using high temperature resistant, corrosion resistant paint processing appearance.

2. The console adopts intelligent PID digital display control instrument, good stability, high precision, equipped with ammeter, novel structure.

3. Oven door adopts with thickening, reinforcement to prevent deformation.

4. Lining is made of high quality refractory brick, heat preservation cotton lining forming, heat preservation effect is good, the heating element in it.

5. Furnace temperature detection

6. With overload protection and short circuit protection

7. Wiring is simple, easy to operate

constitute:

Two major parts are composed mainly of furnace and control box . Box-type resistance furnace usually work under the condition of natural atmosphere, mostly within the heating works, do lining refractory and insulation materials. For use on the workpiece for normalizing, annealing, quenching, etc. Heat treatment and other heating purposes. According to the different heating temperature generally is divided into three types, Temperature higher than 1000 °C is called high temperature box type resistance furnace, the temperature between 1000 °C in 600 known as the box-type resistance furnace in the temperature, the temperature is below 600 °C as low temperature resistance furnace, box-type tempering in order to meet the needs of different heat treatment temperature.

Note: we are produce non-standard productions according to your requirement. Please don’t hesitate to contract with me !

(1)FXL series 1100 °C box-type resistance furnace

|

model |

Rated power(KW)

|

rated temperature(°C) |

rated voltage(V) |

phase |

chamber size (length×wide×high) (mm)

|

|

FXL-16-11 |

16 |

1100 |

380 |

3 |

500×350×300 |

|

FXL-18-11 |

18 |

1100 |

380 |

3 |

600×350×300 |

|

FXL-21-11 |

21 |

1100 |

380 |

3 |

700×400×400 |

|

FXL-28-11 |

28 |

1100 |

380 |

3 |

750×500×450 |

|

FXL-30-11 |

30 |

1100 |

380 |

3 |

950×500×450 |

|

FXL-45-11 |

45 |

1100 |

380 |

3 |

1200×600×450 |

|

FXL-65-11 |

65 |

1100 |

380 |

3 |

1500×750×500 |

|

FXL-75-11 |

75 |

1100 |

380 |

3 |

1800×900×600 |

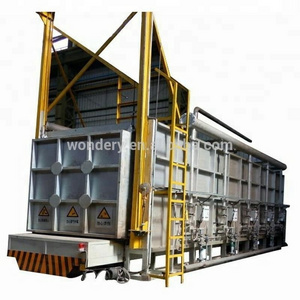

( 2)FXL series 1100 °C box-type atmosphere protection resistance furnace

Main application : Mainly used for less oxidation quenching, annealing heat treatment

|

model |

Rated power(KW)

|

rated temperature(°C) |

rated voltage(V) |

phase |

chamber size (length×wide×high) (mm)

|

|

FXL-24-11 |

24 |

1100 |

380 |

3 |

600×350×300 |

|

FXL-35-11 |

35 |

1100 |

380 |

3 |

700×400×350 |

|

FXL-50-11 |

50 |

1100 |

380 |

3 |

1000×450×500 |

|

FXL-65-11 |

65 |

1100 |

380 |

3 |

1200×600×400 |