- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Fuyuan

-

Voltage:

-

380V

-

Power:

-

6.5KW

-

Dimension(L*W*H):

-

5900*2800*1880mm.

-

Weight:

-

3500 kg

-

Marketing Type:

-

New Product 2023

-

Name:

-

Kitchen towel making machine

-

Finish products:

-

Kitchen towel/Toilet tissue

-

Control system:

-

PLC, touch screen

-

Back paper stand:

-

3 layers

-

Embossing roller:

-

Customized

-

Lamination:

-

1 set

-

Air pressure:

-

0.8Mpa

-

Capacity:

-

3-4 tons

-

Raw material:

-

Jumbo tissue roll

-

After-sales Service Provided:

-

Product instructions, engineer guidance, installation video

Quick Details

-

Production Capacity:

-

200m/min

-

Product Type:

-

Kitchen towel

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Fuyuan

-

Voltage:

-

380V

-

Power:

-

6.5KW

-

Dimension(L*W*H):

-

5900*2800*1880mm.

-

Weight:

-

3500 kg

-

Marketing Type:

-

New Product 2023

-

Name:

-

Kitchen towel making machine

-

Finish products:

-

Kitchen towel/Toilet tissue

-

Control system:

-

PLC, touch screen

-

Back paper stand:

-

3 layers

-

Embossing roller:

-

Customized

-

Lamination:

-

1 set

-

Air pressure:

-

0.8Mpa

-

Capacity:

-

3-4 tons

-

Raw material:

-

Jumbo tissue roll

-

After-sales Service Provided:

-

Product instructions, engineer guidance, installation video

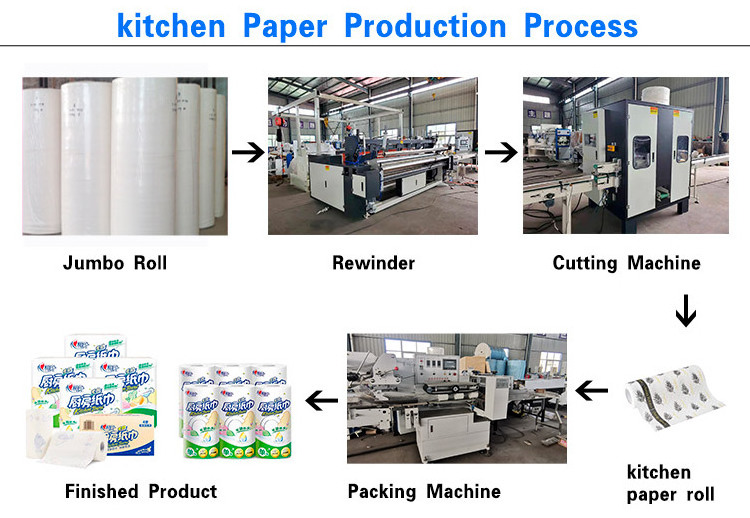

Kitchen paper roll machine

1.The machine is professional in making paper rolls and color glue lamination rolls with wallboard type structure, the

machine can work stable without any noise.

2.This machine is used for making toilet paper roll and kitchen towel paper,perforation distance is adjustable,meeting

different requirements.

3.Automatic core feeding system,automatic pushing the log after rewinding,then rewinding the new log again.so reducing

shortcut waste and save the cost.

4.Adopts international advanced plc programmable controlling technique ,man-machine interface operation,data set and

parametric fault shows on touch screen

5.Three horizontal type back stands,pneumatic loading system, with width driving flat belts,each jumbo roll can be

adjusted independently.

6.Adopt 4 pieces high precision spiral knives, low noise,clear perforation,adopt gearbox to have bigger range.

7.Adopt jogging switchs for wearing the paper,easy and safe to operate

8.Individual wallboard type color glue lamination device ,the structure is consist of two set embossing roller steel to

rubber and lamination device.

|

Machine Type

|

FY-1575

|

FY-1880

|

FY-2400

|

FY-2800

|

|||

|

Paper Width

|

1575mm

|

1880mm

|

2400mm

|

2800mm

|

|||

|

Jumbo roll dia

|

1200mm or 1500mm

|

20~150mm

|

40~200mm

|

40~250mm

|

|||

|

Jumbo Roll Core Diameter

|

Standard 76mm

|

|

|

|

|||

|

Finished Diameter

|

90-150mm, can be customized to 300mm for maxi roll

|

|

|

|

|||

|

Machine Speed

|

200-240m/min

|

5.5KW

|

11KW

|

11KW

|

|||

|

Parameter Setting

|

PLC computer operating system interface

|

2.9*1.9*1.7m

|

4*2*1.95m

|

4*2*1.9m

|

|||

|

Optional Unit

|

1.Full Embossing Unit:Steel to Rubber

2.Edge Embossing Unit: Steel to Steel 3. Color Glue Lamination Unit 4. Color Printing Unit 5.Ultraviolet disinfection device 6.Perfume Unit |

2800kg

|

3200kg

|

3200kg

|

|||

1、The Full Automatic Toilet Paper Machines production chart: Unwinding — Embossing —Glue Lamination—Perforating—Rewinding—Automatic core loading — Tail-gluing — Edge trimming.

2、 Automatically change the paper core, also can produce toilet paper roll without roll core.

3.、Automatic Tail-trimming, gluing, gluing at the same time

Packaging &Delivery

Packaging:

1. Fixed all the movable parts with plastic films.

2. Polystyrene foam plate wrapped around.

3. Wrapped with tighted plastic films several circles.

4. Fixed machine on the fumigated plywood pallet with iron wire.

5. Wrapped with wooden board around and nailed on.

Shipment:

1. Sea transportation is from Qingdao port or other ports.

2. The delivery time is decided by your needed machines or machine parts. But it also follows your needs.

After Sales:

1

. Fast Safe Delivery.

2. Assisting our clients for foundation construction of equipments.

3. Dispatching engineers to install and debug equipments.

4.Training the first-line operators one site.

5. One year warranty, we provide free machine parts within one year.

6. Factory Acceptance Test (check-out)

Upon request, a machine test run can be carried out at the supplier’s factory,

suitable to demonstrate compliance to the purchase order.

Company profile

Henan Fuyuan Machinery Manufacturing Co., Ltd

l

ocated in Zhengzhou City, Henan Province.Our factory is founded in

1984 with rich experience in paper making machine. Our main products include:egg tray machine, toilet paper rewinding machine,

napkin paper

machine and facial paper machine. After 36 years of development, our company has developed into a large enterprise

integrating

scientific research, pro

duction and trading,our factory covers an area more than 33,000 square meters, construction area

more than

16,000 square meters, existing staff more than 200 workers, including 5 senior engineers, 22 engineers, and more than 38

technical staff.

We are committed to provide customers with a complete solution for paper making project and paper egg tray making production line

welcome the friends to visit us over the world.

Hot Searches