- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

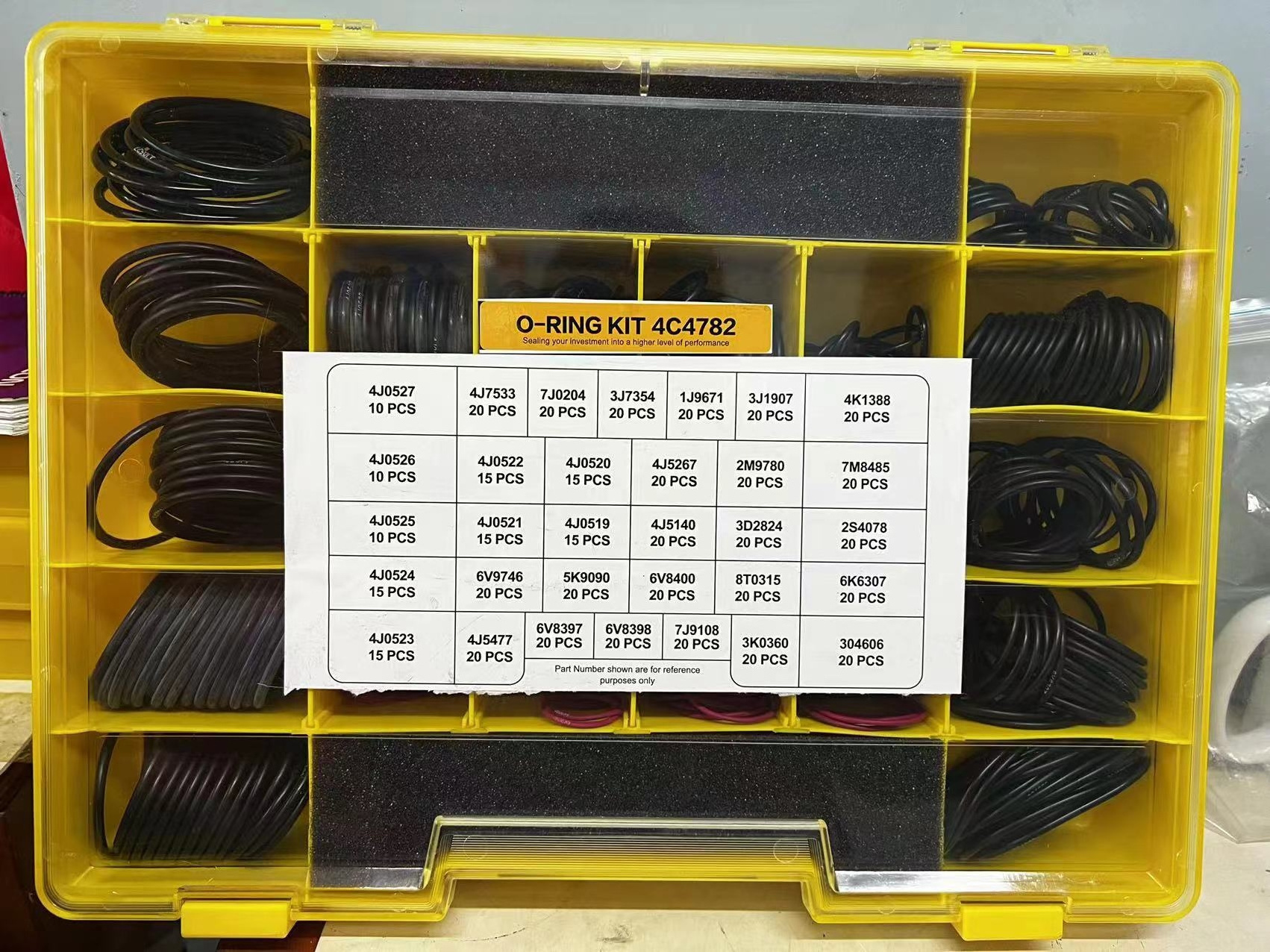

270-1528 4C4782 O Ring Kit

-

Brand:

-

DLSEALS

-

Item Name:

-

O Ring Kit

-

Model:

-

270-1528 4C4782 O Ring Kit

-

Material:

-

NBR

-

Color:

-

Black, Red

-

MOQ:

-

10 Sets

-

OEM:

-

Accpetable

-

Application:

-

CAT Excavator

Quick Details

-

Size:

-

Standard, Standard

-

Place of Origin:

-

Guangdong, China, Guangdong, China

-

Brand Name:

-

DLSEALS

-

Model Number:

-

270-1528 4C4782 O Ring Kit

-

Brand:

-

DLSEALS

-

Item Name:

-

O Ring Kit

-

Model:

-

270-1528 4C4782 O Ring Kit

-

Material:

-

NBR

-

Color:

-

Black, Red

-

MOQ:

-

10 Sets

-

OEM:

-

Accpetable

-

Application:

-

CAT Excavator

|

Product Name

|

O-ring Kit 270-1528 4C4782

|

|

Material

|

NBR

|

|

Color

|

Black, Red

|

|

Standard or Nonstandard

|

Standard

|

|

MOQ

|

10 sets

|

|

Application

|

CAT Excavator

|

|

DLSEALS Rubber O-Ring Seals

|

|

|

|

|

||||

|

Material

|

Hardness (Shore A)

|

Temperature

|

Size

|

|

||||

|

|

|

|

Standard Size

|

Available

|

||||

|

NBR(Buna,Nitrile)

FKM(FPM)

EPDM

Silicone(VMQ)

HNBR

FFKM

PU

PTFE

|

60-90

70-90

60-90

10-70

60-90

70-90

90~95(D)

60~70(D)

|

-55℃-110℃

-20℃-250℃

-45℃-150℃

-60℃-280℃

-48℃-180℃

-18℃-326℃

-40℃-90℃

-100℃-280℃

|

AS-568(USA)

JIS-B2401(Japan)

DIN-3771(Germany)

BS-1516(UK)

ISO3601(International)

R(France)

|

Diameter of seals from0.5-3500mm

|

||||

|

Resistance

|

Color

|

Certificate

|

Application

|

|

||||

|

Hydraulic Fluid

Engine Oil

Chemical

Ozone

Steam & Hot Water

Low Temperature

High Temperature

|

Black

Brown

Red

Green

White

Blue

Clear

Customized

|

IS09001

ISO14001

TS16949

RoHS

REACH

F D A

UL94V0

|

Auto Industry

Construction Machinery

Machine Tool Equipment

Food Health

Water Treatment

Chemical Processing

Hydraulic Pneumatic

Industrial Manufaturing

|

|

||||

NBR orings(nitrile butadiene rubber)

FKM, o-rings(Fluorocarbon)

Silicone Rubber o ring (Q, MQ, VMQ, PVMQ)

PU o-rings(Polyurethane)

PU displays higher mechanical strength, high abrasion, wear and extrusion resistance, high pressure load capacity, as well as a high tear and elongation at break resistance.

PU is suitablefor for application in mineral oils and greases, hydraulic oils, silicone oils and greases, highly non-flammable hydraulic fluids HFA and HFB and water uo to 50℃.

PTFE O-Rings

*Service Temperature

PTFE's mechanical properties are low compared to other plastics, but its properties remain at a useful level over a wide temperature range of -100°F to +400°F (-73°C to 204°C).

*Application

PTFE is the common sealing material used for making wear ring, backing-up ring, o ring, gasket, etc. It can be found in metallurgy machinery, petrochemical machinery, engineering machinery, and light industrial machinery.

Ethylene Propylene Rubber (EPM, EPDM)

*Service Temperature

For EPDM the service temperature can be designed from -55 C to 125 C or up to 150 C (for peroxide cured systems).

*Application

In phosphate-ester based hydraulic fluids and glycol based brake fluids systems Ethylene Propylene Rubber is good choice for

sealing parts. EPDM is also is usually used in hot water or steam applications up to 150 C.

alcohols, glycols and aromatics. The molecular structure contains ethyl acrylate (EA), butyl acrylate (BA) and methoxyethyl

acrylate (MEA). High BA content improves low temperature resistance and high MEA content improves oil resistance.

We are manufacturer.We are based in Guangdong, China, start from 2010,sell to Domestic Market(33.00%),North

America(15.00%),SouthAmerica(10.00%),Western Europe(8.00%),Eastern Europe(6.00%),Southern Europe(6.00%),Southeast Asia(5.00%),MidEast(5.00%),Northern Europe(5.00%),Oceania(2.00%),South Asia(2.00%)

2. What are the standards for DLSEALS O-rings?

C92/C82/C76 (China), AS568 (USA), BS (UK), R (France), P.G (Japan) , etc.

3.What are the materials of DLSEALS O-rings?

4. What are the size ranges of DLSEALS O-rings?

ID0.5 to 3500MM can be produced, support customization

5. What is the stock status of DLSEALS O-rings?

DLSEALS has a large stock of NBR O'RING, Silicone O'RING, FKM/VITON ORING

6. Which certifications do DLSEALS O-rings comply with?

ROHS,REACH,F D A,UL94V0/V1 , etc.

7. What is the production time for DLSEALS O-rings?

For more information, please contact us. We look forward to your arrival