- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

The Machines classification:

-

Building Stone Production Line

-

Color:

-

Customer Requirement

-

Advantage:

-

Higher Efficiency

-

Product name:

-

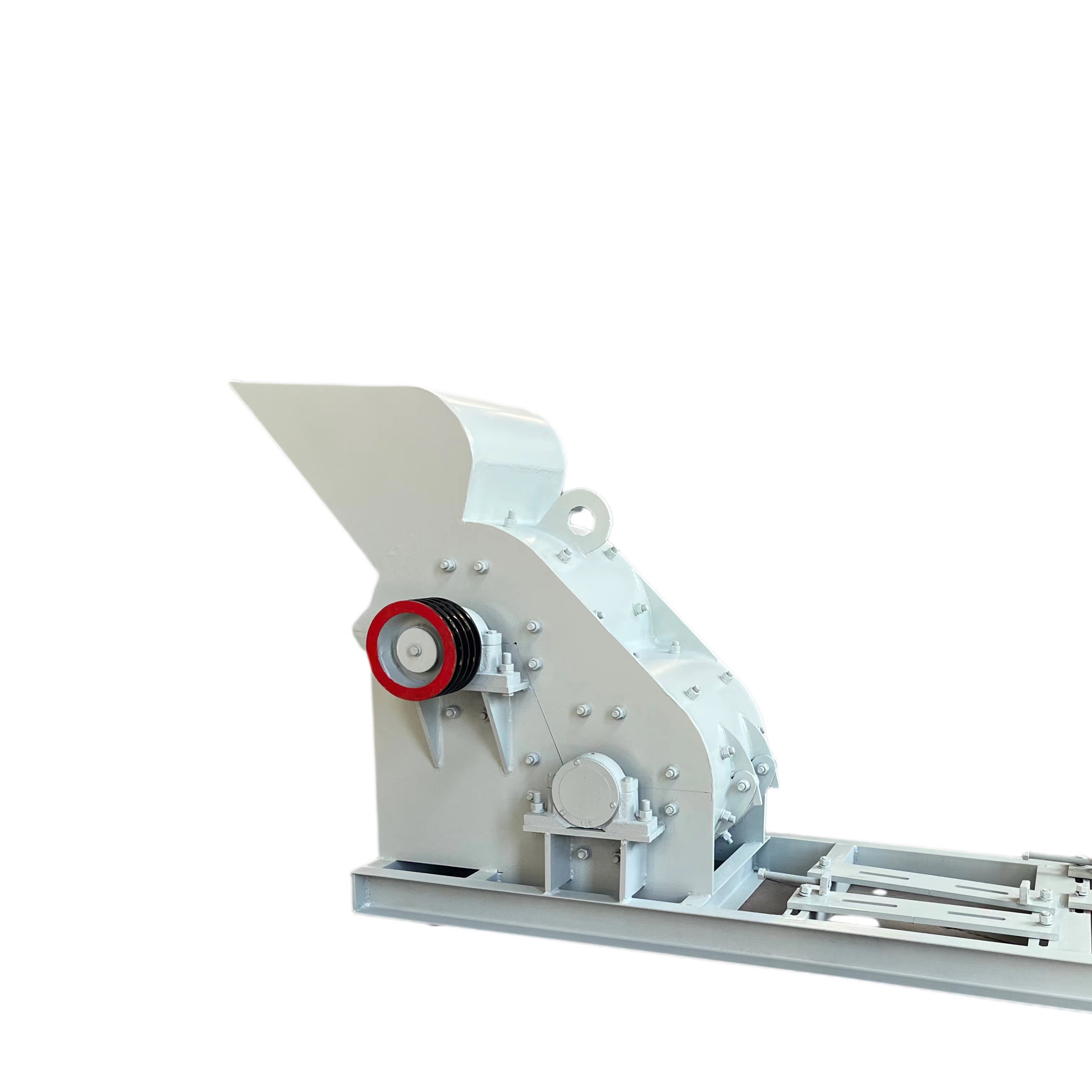

Hammer Crusher Machine

Quick Details

-

Application:

-

stone,ore,coal,sand, Quarry

-

Place of Origin:

-

Henan, China (Mainland)

-

Weight:

-

2200 KG

-

Marketing Type:

-

Hot Product 2023

-

The Machines classification:

-

Building Stone Production Line

-

Color:

-

Customer Requirement

-

Advantage:

-

Higher Efficiency

-

Product name:

-

Hammer Crusher Machine

Product Overview

Rock Crusher Rock Hammer Mill Plant Used Stone Crusher To Sand Making Machine

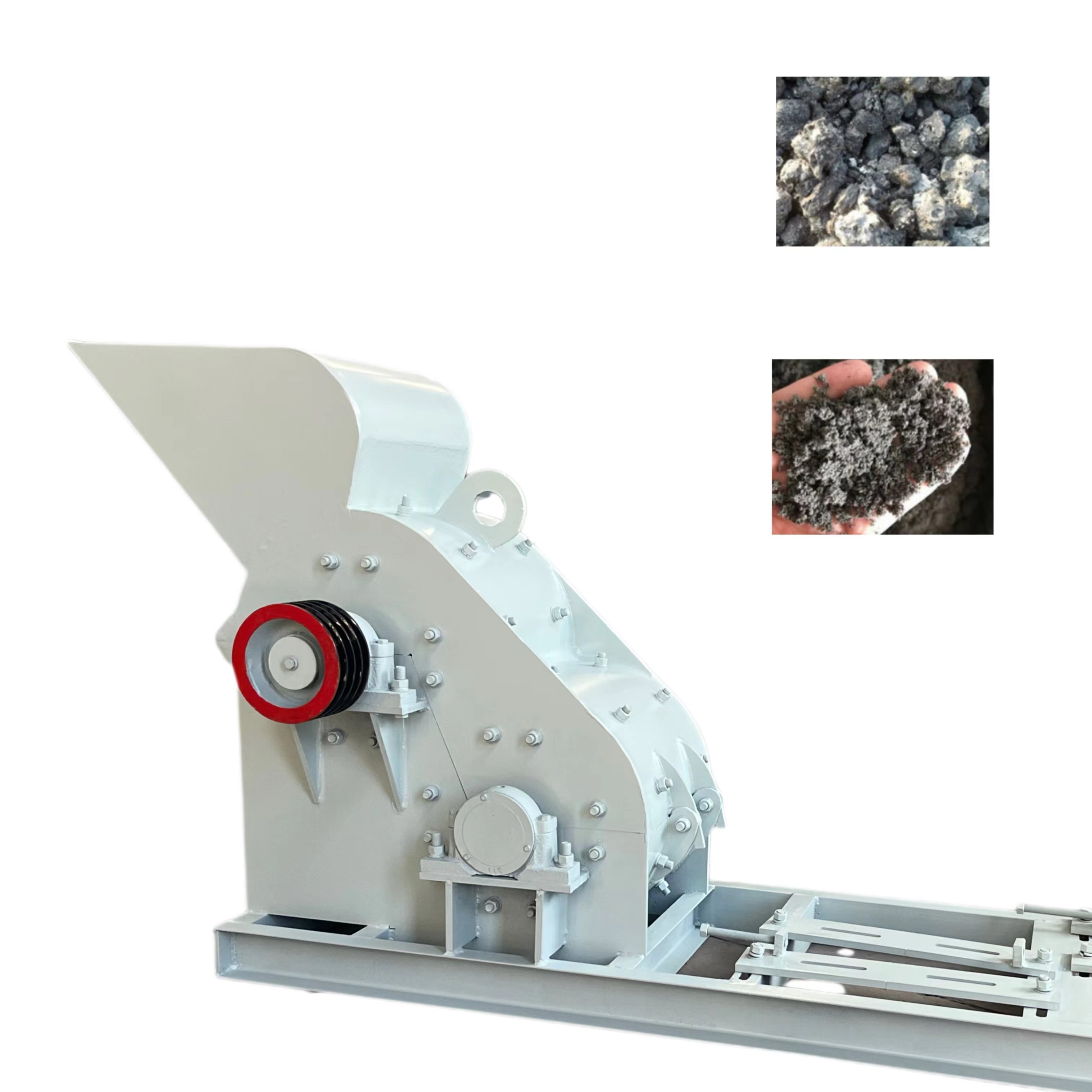

two-stage crusher is a type of equipment used for crushing materials, comprising two stages of crushing: primary crushing and secondary crushing. In primary crushing, larger materials are crushed into smaller chunks, while secondary crushing further refines the materials crushed in the primary stage, resulting in more uniform and finer particles. This equipment is commonly used in industries such as mining, construction, and chemical engineering. Through the two-stage crushing process, the desired particle size and shape can be achieved, thereby improving the quality of the product.

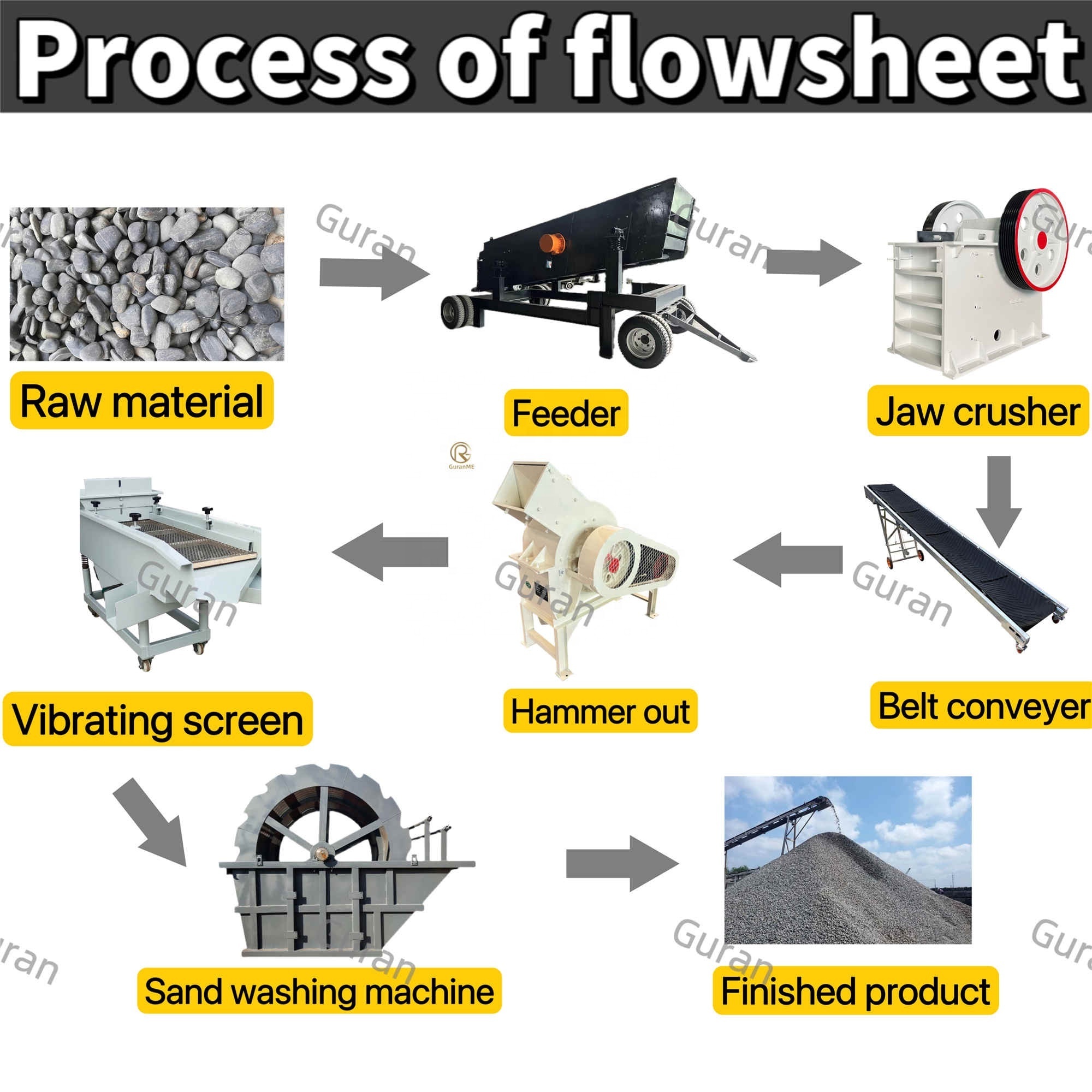

FEATURES AT A GLANCE

Suitable for coarse, medium and fine crushing of all kinds of ores and rocks

cobblestone

▼▼▼

iron ore

▼▼▼

gray stone

▼▼▼

Working principle of Hammer Crusher

During operation, driven by the motor, the two sets of rotors rotate simultaneously at high speed. The upper rotor crushes the rawmaterial in the cavity, which is then finely ground by the rapidly rotating lower rotor and hammer. The materials in the cavitycollide rapidly, mutually grinding, resulting in an effective hammering and powder formation. This process leads to the dischargeof particles with a granularity smaller than 3 mm.

Details Images

PRODUCT SPECIFICATIONS

Our equipment comes in a variety of models to meet your needs and can be customized according to your requirements.

|

Model

|

Hammer Quantity

|

Capacity (t/h)

|

Motor power (kw)

|

Total weight (t)

|

Dimensions (L*W*H)(mm)

|

|

600*400

|

24

|

10

|

4 pole 18.5kw*2

|

1.1

|

2600*800*1500

|

|

600*600

|

40

|

20

|

4 pole 22kw*2

|

1.3

|

2700*1200*1500

|

|

600*800

|

48

|

20-30

|

4 pole 22kw+28kw

|

1.8

|

2800*1350*1600

|

|

800*800

|

48

|

40-50

|

4 pole 55kw+45kw

|

3.5

|

3200*1400*2000

|

|

1000*1000

|

60

|

60-70

|

4 pole 90kw+75kw

|

7

|

3900*1830*2500

|

|

1000*1400

|

66

|

100-120

|

4 pole 110kw+132kw

|

10

|

3900*2300*2500

|

|

1400*1600

|

60

|

130-180

|

4 pole 160kw+200kw

|

22

|

6000*3100*3900

|

Why Choose Us

We have sufficient supply and rich field experience

Each equipment is strictly tested before leaving the factory to ensure that customers receive high-quality and reliable products. Customer satisfaction is our ultimate goal, we have established a perfect pre-sale, sale, after-sales service system.

our services

Pre-Sale Service:

1.We offer various pre-sales services to help customers plan their investments and manufacturing with reduced costs.

2.After assessing customers' goods and sizes, we recommend the most suitable machines.

3.We suggest machines based on customers' usage and budget.

In-Sale Service:

1.We provide step-by-step manufacturing photos for customers to review.

Packing and shipping are arranged according to customers' needs.

2.Machines are tested, and videos are provided for customer inspection.

After-Sale Service:

1.We guarantee machine quality for one year.

2.Free training and timely technical support are provided to address any questions or concerns.

Paking & Delivery

All the wear out spare parts are packed by plastic films and wooden boxes.

FCL: Shipping by standard exporting container.

LCL :Poly wood case.

LCL :Poly wood case.

Hot Searches