- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

XINHENGDA

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

6*3*2.5M

-

Hollow part volume:

-

20-125

-

Screw L/D Ratio:

-

25

-

Screw diameter (mm):

-

90 mm

-

Screw Heating Power(kW):

-

40 kW

-

Extruder Motor Power(kW):

-

30 kW

-

Mold Platen Size(Width)(mm):

-

1152 mm

-

Mold Platen Size(Height)(mm):

-

930 mm

-

Air Pressure(MPa):

-

0.4 MPa

-

Air Comsumption(m³/min):

-

1 m³/min

-

Die Head Heating Power(kW):

-

30 kW

-

Accumulator Capacity(L):

-

7.5 L

-

Power (kW):

-

100

-

Weight (T):

-

10

-

After-sales Service Provided 1:

-

Online support

-

After-sales Service Provided 2:

-

Field installation, commissioning and training

-

After-sales Service Provided 3:

-

Field maintenance and repair service

-

After-sales Service Provided 4:

-

Video technical support

Quick Details

-

Clamping Force (kN):

-

200

-

Output (kg/h):

-

100 kg/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

XINHENGDA

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

6*3*2.5M

-

Hollow part volume:

-

20-125

-

Screw L/D Ratio:

-

25

-

Screw diameter (mm):

-

90 mm

-

Screw Heating Power(kW):

-

40 kW

-

Extruder Motor Power(kW):

-

30 kW

-

Mold Platen Size(Width)(mm):

-

1152 mm

-

Mold Platen Size(Height)(mm):

-

930 mm

-

Air Pressure(MPa):

-

0.4 MPa

-

Air Comsumption(m³/min):

-

1 m³/min

-

Die Head Heating Power(kW):

-

30 kW

-

Accumulator Capacity(L):

-

7.5 L

-

Power (kW):

-

100

-

Weight (T):

-

10

-

After-sales Service Provided 1:

-

Online support

-

After-sales Service Provided 2:

-

Field installation, commissioning and training

-

After-sales Service Provided 3:

-

Field maintenance and repair service

-

After-sales Service Provided 4:

-

Video technical support

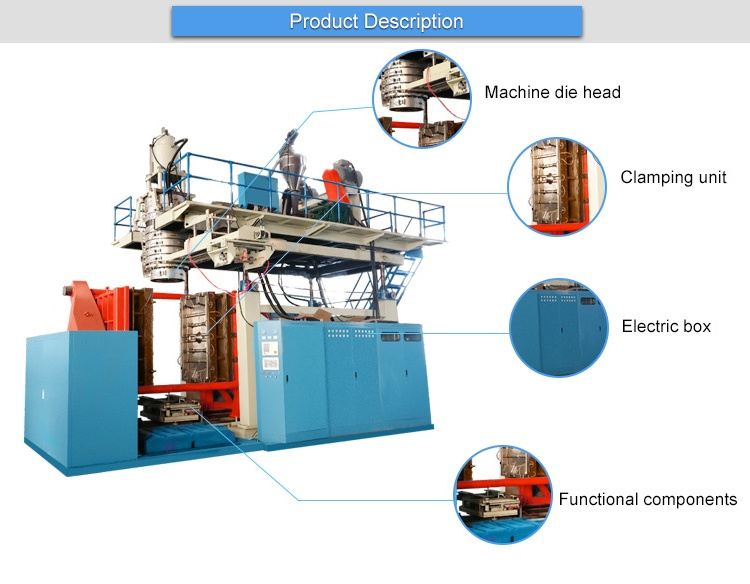

125 liter 3 layers Plastic Blow Molding Machine.

The product satisfy GB13508-92, SN04499.2-95 requirement.

Material:HDPE

XHD125L Full automatic Plastic blow molding machine.

Thickness control system : Japanese MOOG 200 points.

Down-shot unit : multifunction.

Automatic pick-off: multifunction.

The screw adopts IKV design, with high potency melt to make sure the material well mixed.

-Adopt frequency control of motor system to reduce the power consumption.

-Adopt Parison thickness controller Moog 100 points, to make thickness even and adjust the tank weight in big span.

-Fully automatic, easy to operate, two women can operate machine, whole production line need 3 or 4 person only.

-High output versus Roto molding machine

-Save raw material 25% - 35% versus Roto tanks.

-Perfect impact resistance versus Roto tanks.

-Multi layers co-extrusion.

-The mechanical arm can take out the product automatically.

Product Application

Verticaltank, horizontal tank, square tank, garbage can,chemical plastic barrels, septic-tank, road barrels,blow molding toy, toolbox, float, boat, furniture,pallet, combination tank, pressure-vessel, injection cap mold design.

| MAIN PARAMETERS | |||

| MACHINE MODEL | UNIT | XHD 125-2 | XHD 125-3 |

| Capacity Range | L | 20-125 | 20-125 |

| Number of Layers | Layers | 1-2 | 1-3 |

| We can make 1-6 layers. | |||

| Machine Size (L*W*H) | M | 6*3*4.5 | 6*3*4.5 |

| Machine Weight | Ton | 12 | 14 |

| Total Power | KW | 146 | 171 |

| MAIN PARAMETERS | |||

| MACHINE MODEL | UNIT | XHD 220-2 | XHD 220-3 |

| Capacity Range | L | 120-220 | 125-220 |

| Number of Layers | Layers | 1-2 | 1-3 |

| We can make 1-6 layers. | |||

| Machine Size (L*W*H) | M | 8*3.5*6.2 | 8*3.5*6.2 |

| Machine Weight | Ton | 20 | 22 |

| Total Power | KW | 292 | 345 |

| CONFIGURATION | |

| NAME | BRAND |

| LOW-VOTAGE APPRATUS | SIEMENS |

| PNEMATIC | SNTC & AIRTAC |

| HYDRAULIC COMPONENT | YUKEN |

| SEAL | DICHTOMATIC GERMANY AND TAIWAN DZ |

| SCREW MOTOR | SIMENS |

| PROXIMITY SWITCH | AUTONICS |

| PLC | SIMENS |

| TOUCH SCREEN | PROFACE (JAPAN) |

| LINEAR GUIDEWAY | HIWIN TAIWAN |

| THICKNESS CONTRAL SYSTEM | MOOG(JAPAN)(200 POINTS) |

| FREQUENCY CONVERTERS | ABB |

| SERVO CONTROL | DELTA(TAIWAN) |

| SERVO MOTOR | PHASE ITALY |

| OIL PUMP | SUMITOMO JAPAN |

TEST METHOD ASTM D1238, ISO 1133 21.6KG 190℃

MELT FLOW RATE(MFR)

MFR 2-12 SUITABLE BIG SIZE PRODUCT

MFR 2-4 PALLET, 5000L WATER TANK, 10000L WATER TANK

MFR 4-8 1000L-3000L WATER TANK

MFR 8-12 200-2000L WATER TANK

| Detailed Images |

| OUS SERVICES |

Pre-Sales Service |

After-Sales Service |

| * Inquiry and consulting support. | * Training how to instal the machine, training how to use |

| * Sample testing support. | the machine. |

| * View our Factory. | * Engineers available to service machinery overseas. |

Weifang Sehenda Machinery Co., LTD is major in plastic machinery and is one of the biggest manufacturer of plastic hollow units. Its main product is plastic machinery. The main products of plastic machinery are automatic hollow plastic unit, pull units, film unit, strapping machine, crusher, extruder. Its annual sales are nearly 100 million yuan. The company focuses on new product development and technological innovation.And the company has developed hollow units of 25L,50L, 125L, 150L, 220L, 500L,1000L,2000L,3000L,5000L in sequence. Supply comprehensive, timely and thoughtfulservice to the whole customers by our service R&D center.Full range of services throughout includes helping clients with early market research, selecting appropriate models, designing plant layout & equipment layout, Determining the auxiliary equipment, selecting and providing appropriate processing technology and product testing, etc.