- Product Details

- {{item.text}}

Quick Details

-

Main housing material:

-

BRASS

-

Voltage:

-

250Vac

-

Electrical rating:

-

Max.1A Max 70W Max 250V

-

Paddle shaft:

-

Titanium

-

Adjustment:

-

cleaving the paddle

-

Warranty:

-

1 Year

Quick Details

-

Media Type:

-

Liquid

-

Item:

-

R1V

-

Application:

-

Flow detection

-

Main housing material:

-

BRASS

-

Voltage:

-

250Vac

-

Electrical rating:

-

Max.1A Max 70W Max 250V

-

Paddle shaft:

-

Titanium

-

Adjustment:

-

cleaving the paddle

-

Warranty:

-

1 Year

|

Item No.

|

R1V

|

|

Contact

|

Reed switch

|

|

Size & Pressure

|

PN25 & DN ≥15

|

|

Flow sensing

|

Cleavable paddle

|

|

Mounting

|

3/4 " BSPP brass union nut

|

|

Electrical rating

|

≤1A & ≤ 70W & ≤250V

|

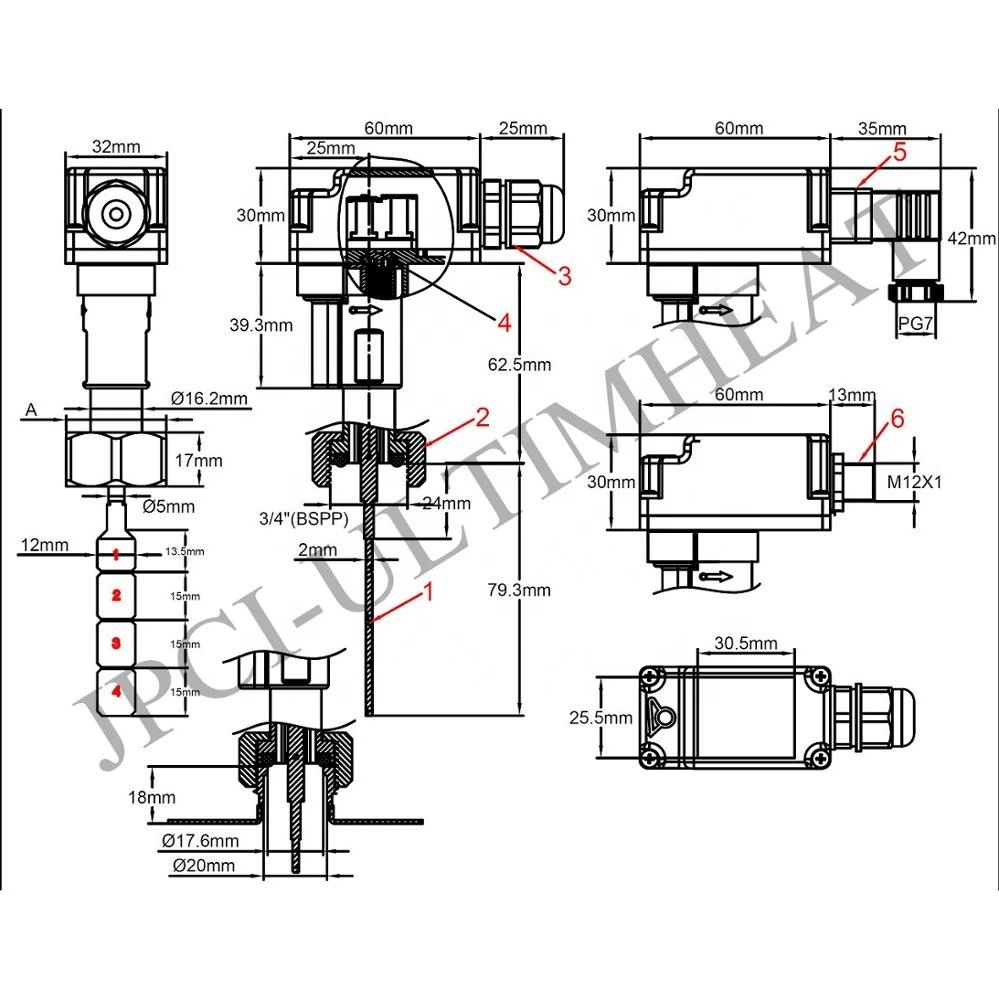

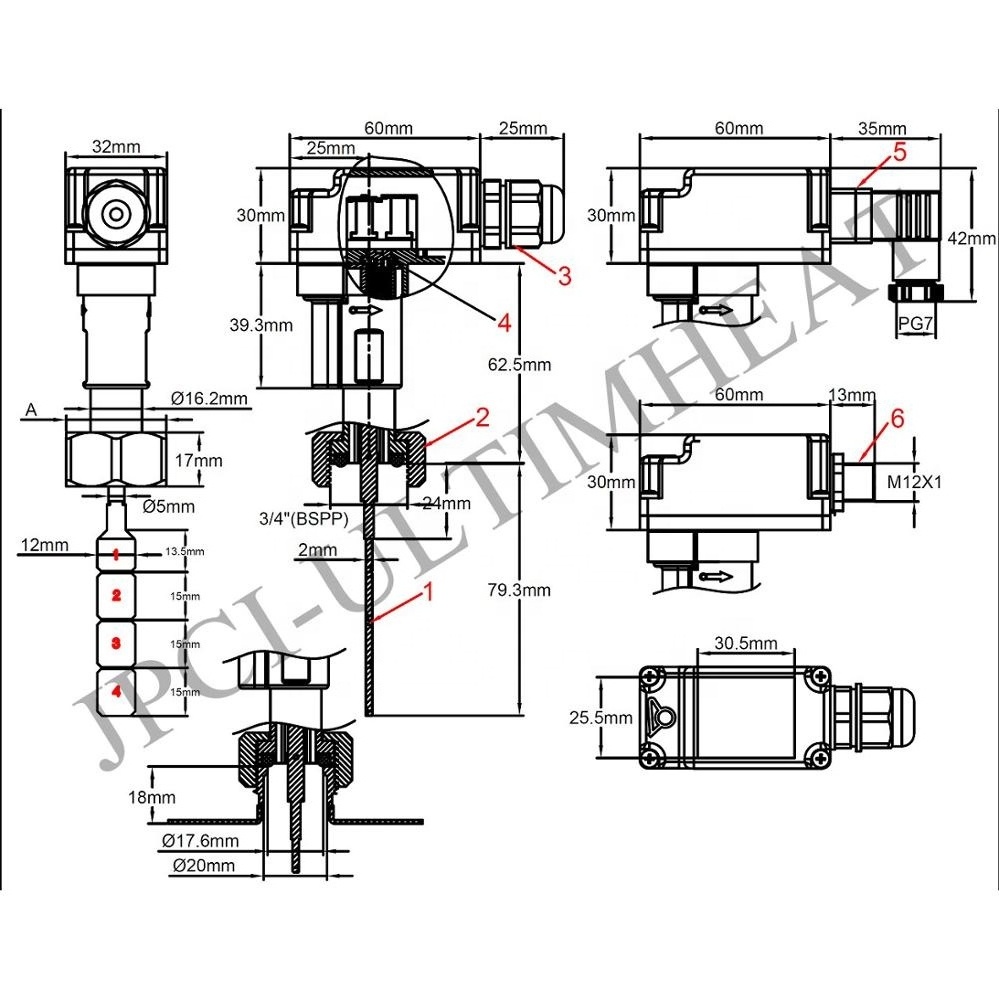

Adjustment:

- By cleaving the paddle

- Fine adjustment by screw driver on internal dial

Paddle shaft: Titanium, providing an outstanding corrosion resistance, and improved mechanical live

Main housing material: Brass

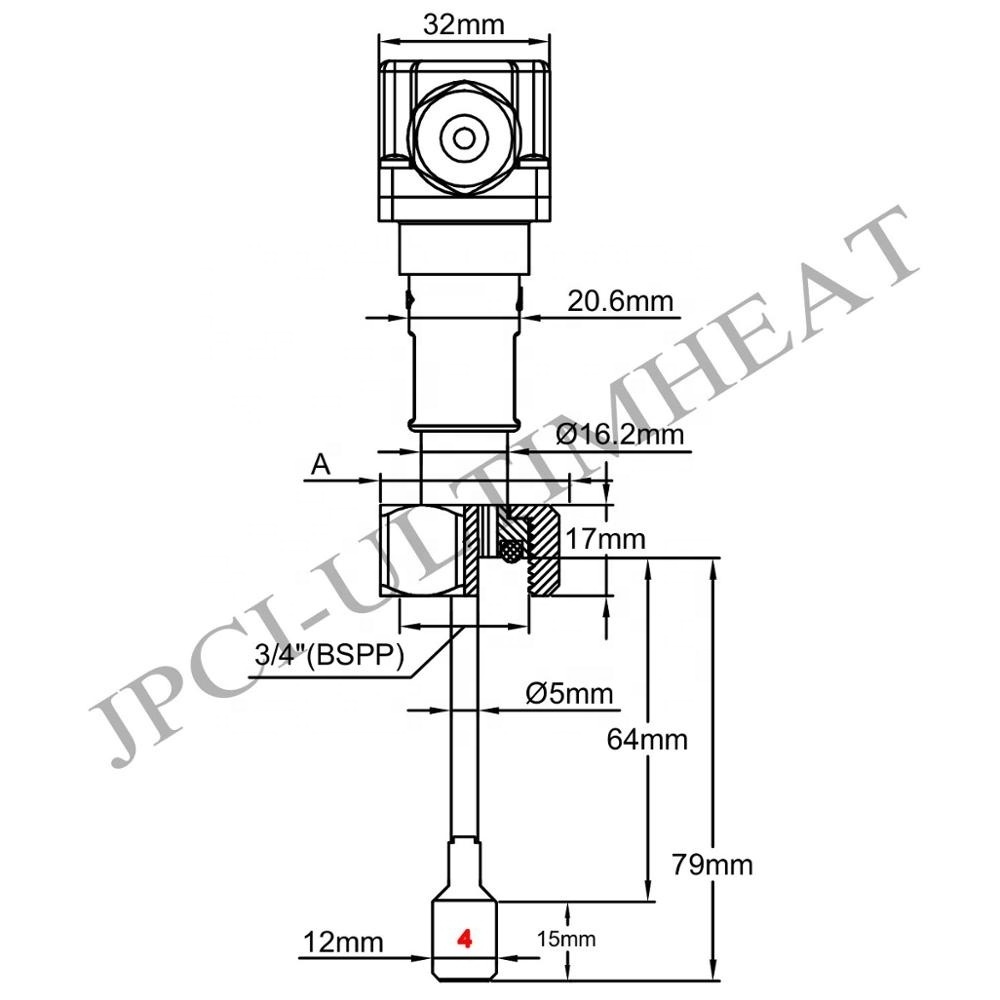

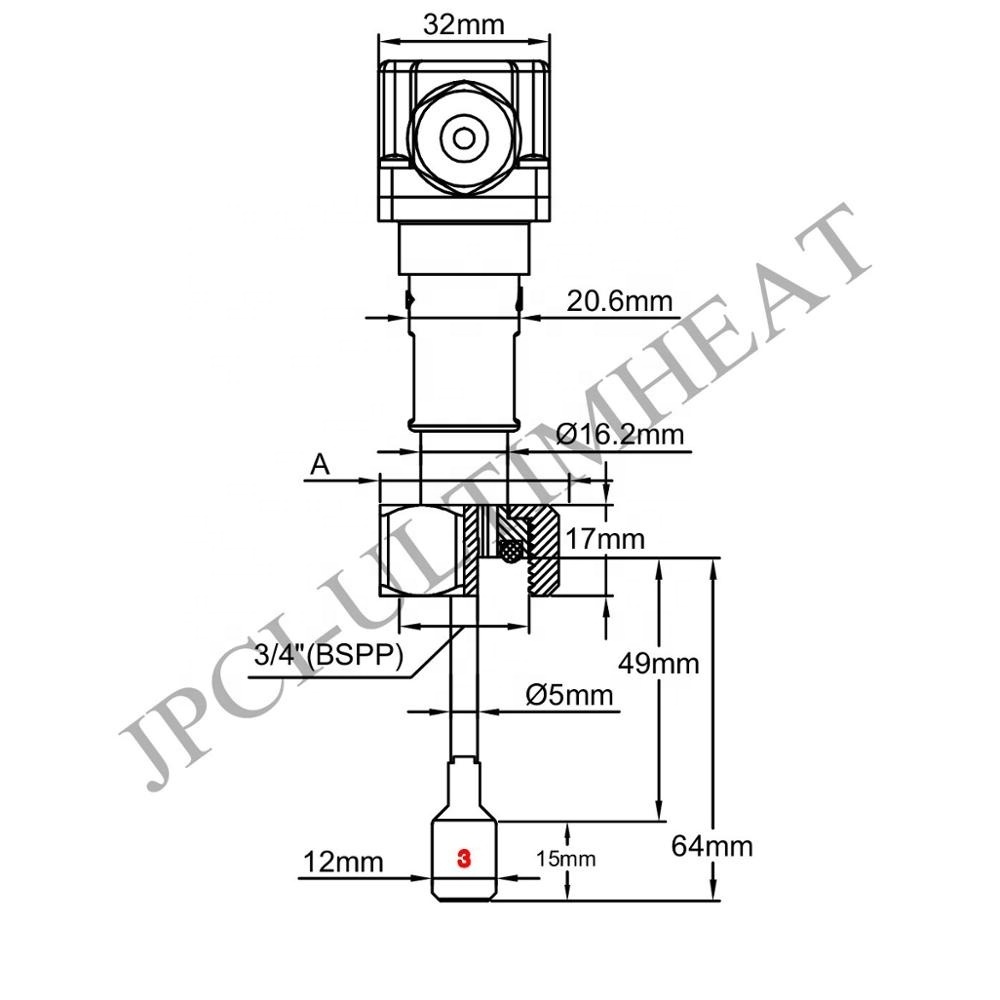

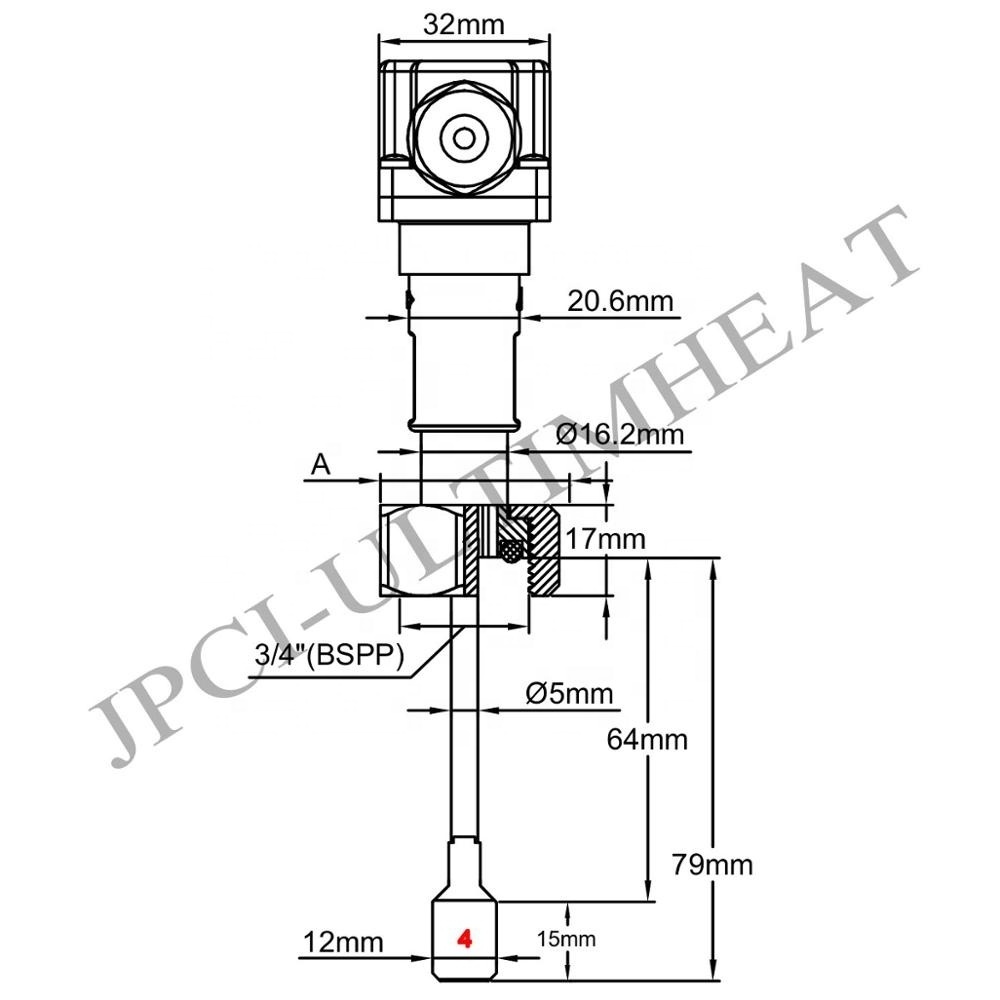

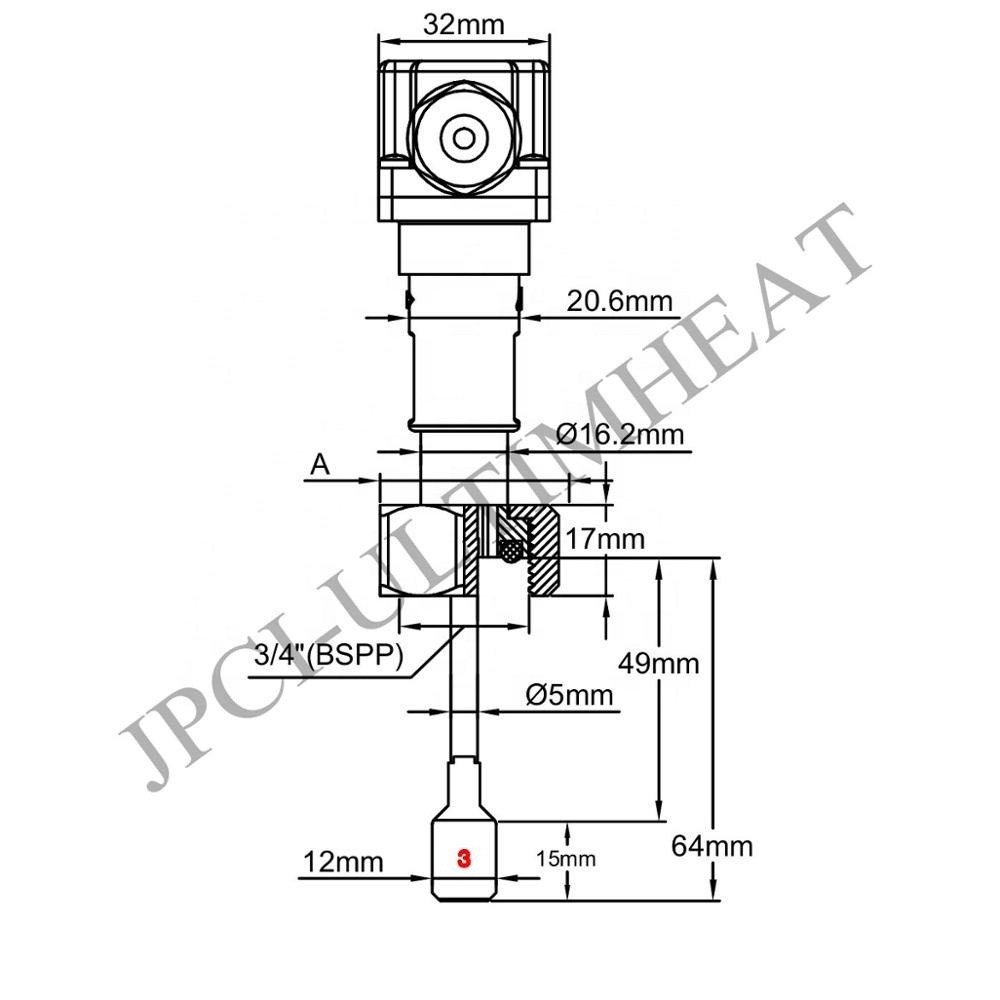

Paddle: Polypropylene, 15 mm width, with 4 sections, numbered 1 to 4, can be cleaved for adjustment to pipe size

Pipe mounting: Nickel plated brass union nut,¾ BSPP, mounting on ¾ BSPP male thread with gasket. Recommended torque: 10±1 Nm

Gasket: NBR

Electrical rating: Max 1A, Max 70W, Max 250V, resistive load. Use on inductive circuits reduces electrical rating. We recommend to protect the reed switch with contact protection device when used in inductive loads

Electric contact type: Normally open, closes by flow rise

Liquids compatibility: For use with clean water and liquids without magnetic particles and without chemical incompatibility with brass, PPO and titanium

Nominal pressure at 20°C: 2,5 MPa (PN25)

Liquids temperature range: 5 to 100°C (Do not withstand water freezing inside pipe)

Ambient temperature range: 5 to 80°C

Ingress protection: IP65

Calibration tolerances: +/-15% (on paddle operating force at end of paddle 1)

Electrical connection:

Standard:

IP64 connection box, with screw terminal connection block, M16x1.5 ISO cable gland

Options:

- Connection box with EN17530-803-A (DIN43650-A) connector

- Connection box with IEC947-5-2 M12x1 4 pins connector

Installation instructions:

- Check carefully the paddle orientation: The arrow on housing must be exactly parallel to the pipe

- A 5 mm minimum gap must be respected between end of the paddle and tube wall opposite to the fitting.

- We recommend the use of nozzles of length less than or equal to 18 mm between the gasket seat and the inside of the tube and with an inner diameter greater than or equal to 13.5 mm, to avoid blocking of the paddle.

Accessories: 3/4” male PVC saddles for DN40 to DN100 (OD) PVC pipes, and other fittings: see last section of this catalogue

Important notice: In the case of plastic pipes (PVC, PE), the DN (nominal diameter) corresponds to the outside diameter and wall thickness is variable depending on the application. This must be taken into account to avoid blocking the paddle. In the case of metal pipes, the inner diameter corresponds to the DN. Flow values data are for tubes whose internal diameter corresponds to DN.

|

Main references (With type A cleavable paddle)

|

|

|

|

|

||||

|

Calibration

(Calibration force ±15%, measured at end of paddle N°1) |

Waterproof connection box with M16x1.5 cable gland

|

Waterproof connection box with 4 pins, M12x1

IEC947-5-2 connector |

Waterproof connection box with DIN 43650-A connector

|

|

||||

|

Low span end: 3gr

|

R1V636680G35N00C

|

R1V636680G35N00L

|

R1V636680G35N00D

|

|

||||

|

Middle span:7gr

|

R1V676680G35N00C

|

R1V676680G35N00L

|

R1V676680G35N00D

|

|

||||

|

High span end:14 gr

|

R1V6E6680G35N00C

|

R1V6E6680G35N00L

|

R1V6E6680G35N00D

|

|

||||

Company profile:

Established in China since 2000, with French technology and investment, our company is proud to have more than 60 years experience in manufacturing electromechanical components and 30 years experience in manufacturing safety component for Spas, swimming pools and hot tubs. This experience, combined with high tech equipment and high tech raw materials let us develop the new components needed by rapid expansion of Asian and Chinese market.

In our new factory, on more than 8000 square meters production lines, we have two manufacturing divisions:

Division one is producing components:

Thermostats, energy regulators pressure switches, level switches, flow switches, fire detection fusible links, heating elements and ceramic connection blocks.

Division two is producing complete assemblies and sub assemblies on customer specifications:

Swimming pools heaters, heat pumps backup heaters, spas heaters, small water heaters, immersion heaters, aluminum foils heaters, baseboard and convection heaters sub assemblies

Our R&D team develops new products upon customer specification, taking care of international safety standard (UL, CE, etc.).

We produce our own stamping, bending, plastic injection, zinc alloy injection, and machining.

We are equipped with up to date automatic and CNC TIG welding and laser welding equipment and ultrasonic welding checking.

We have our own climatic room, corrosion testing loops, salt spray testing, and more than 30 specific equipments for products life testing.

Our income quality control laboratory is equipped to check raw material (plastics, metals) physical characteristics and dimensions.

Our finished product control laboratory has more than 200 machines to calibrate and check temperature, pressure, level and flow controls.

From the raw material to the finished product we control every production step. Meet your control equipment demand rapidly and safely is our consistent promises.

Basic Information

Main Markets: North America/ South America/ Eastern Europe/ Southeast Asia/ Africa/ Oceania/ Mid East/ Eastern Asia/ Western/Europe/ Northern Europe/ Southern Europe/ Domestic Market

Member of Ultimheat alliance

(JPCI has been awarded High and new technology certificate by Chinese government.)