- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

dingchen

-

Voltage:

-

220V/380V

-

Power:

-

5.5KW

-

Dimension(L*W*H):

-

2950*1320*1500mm

-

Weight:

-

3000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

Waste Paper

-

Output paper:

-

Craft Paper

-

Production:

-

Craft Paper

-

Capacity:

-

10t/d

-

Color:

-

as your like

Quick Details

-

Production Capacity:

-

Other

-

Product Type:

-

kraft paper

-

Processing Type:

-

kraft paper machine

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

dingchen

-

Voltage:

-

220V/380V

-

Power:

-

5.5KW

-

Dimension(L*W*H):

-

2950*1320*1500mm

-

Weight:

-

3000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

Waste Paper

-

Output paper:

-

Craft Paper

-

Production:

-

Craft Paper

-

Capacity:

-

10t/d

-

Color:

-

as your like

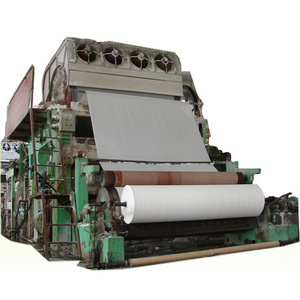

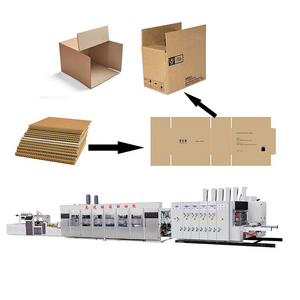

High Quality Kraft Paper/Corrugated Paper Board Making Machine With Recycling Carton Competitive Price

1575mm 10T/D kraft paper production line

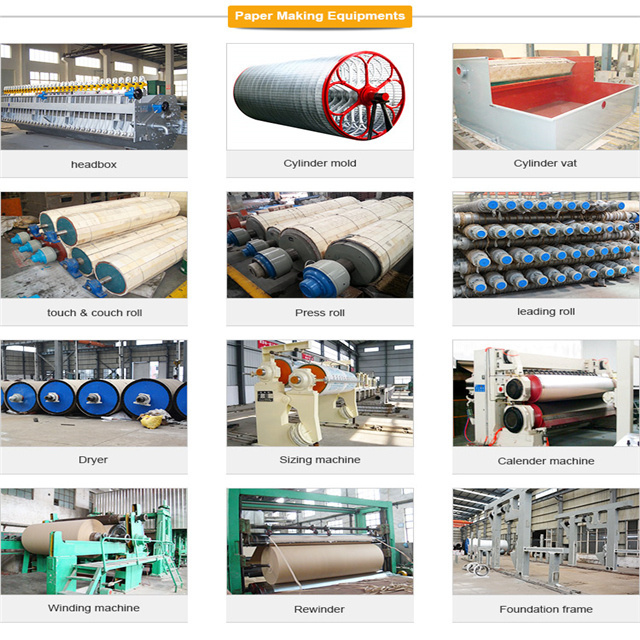

III. Main equipment list for paper production line

No. Item & Description

1 1575mm multi-cylinder and multi-dryer kraft paper machine

2 Exhaust hood of dryer cylinder

3 700 Axial-flow ventilator

4 15 roots vacuum pump

5 Suction box

6 3 rolls calender

7 Frequency conversion controlling cabinet

8 1575mm type horizontal pneumatic winding machine

9 1575mm type frame type upper feeding rewinding machine

10 2T boiler (burning gas)

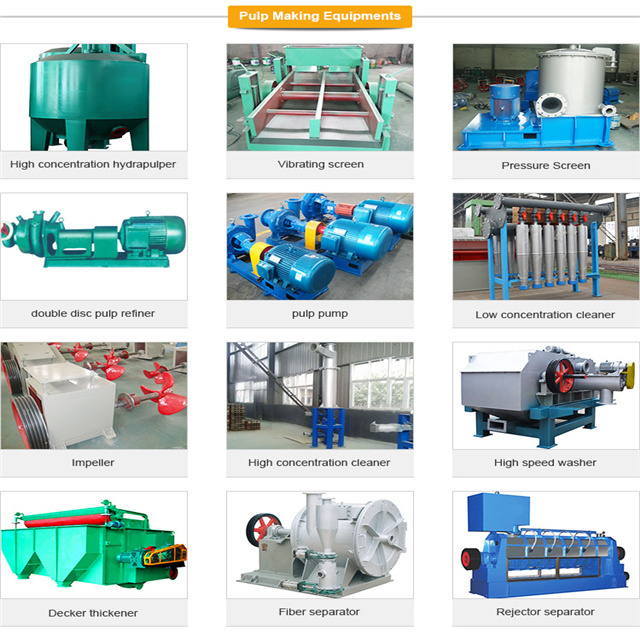

11 3m3 hydra-pulper

12 1.8m2Vibrating screen

13 380Double disc refiner

14 700 propeller

15 1.2m2Pressure screen

16 606 type Sand remover

17 Pulp pump

18 Electric operation cabinet

Our company will select ports for transportation based on different types of machines according to the country where the customer is located. It is usually selected at the port of Qingdao to provide customers with the best possible service.

1.Pre-sales Service

· Offering comprehensive technical and business consultation services;

· Proposing the most suitable scheme and equipment for our clients;

· Designing and fabricating targeted products according to the special re quirements of clients

· Training periodically high qualified service technician.

2.After-sales Service

· Highly inspecting equipments in every working procedure, quality come s first;

· Fast & Safe Delivery;

· Assisting our clients for foundation construction of equipments;

· Dispatching engineers to install and debug equipments;

· Training the first-line operators on site;

· Regularly visit clients to solve production problems;

· Providing life-long maintenance service;

· Providing technical exchanging;