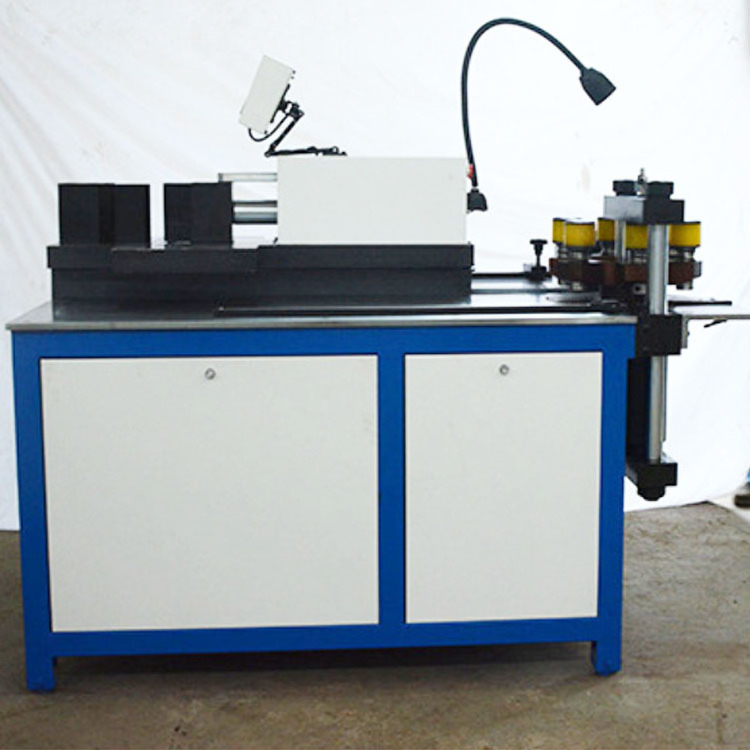

This is a machine that integrates punching, cutting and bending into one, with independent workbenches that do not interfere with each other, greatly improving work efficiency and saving labor costs. Built-in solenoid valve oil pump, using all copper motor, high efficiency and stable operation.

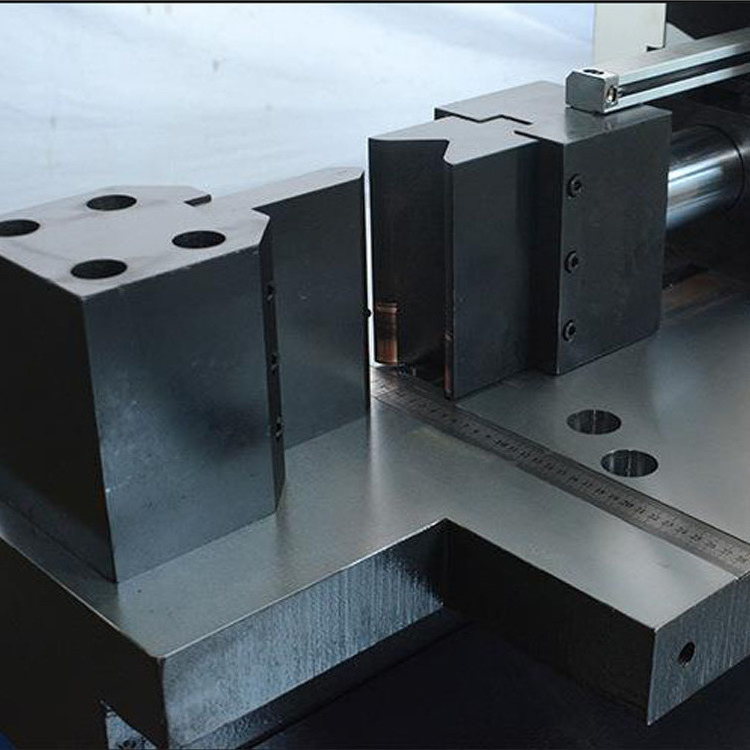

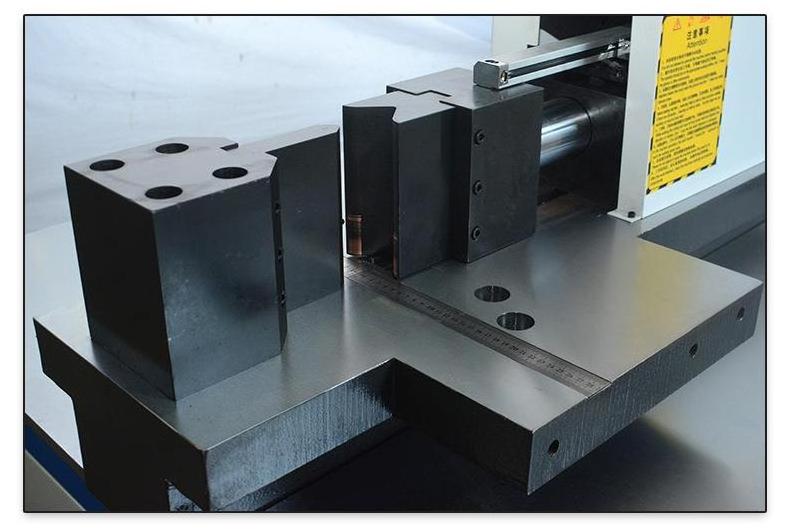

The shearing unit adopts double column and double knife shearing structure, the upper and lower knives are installed vertically and parallel to each other, which makes the cutting edge smooth, less burr and no scrap.

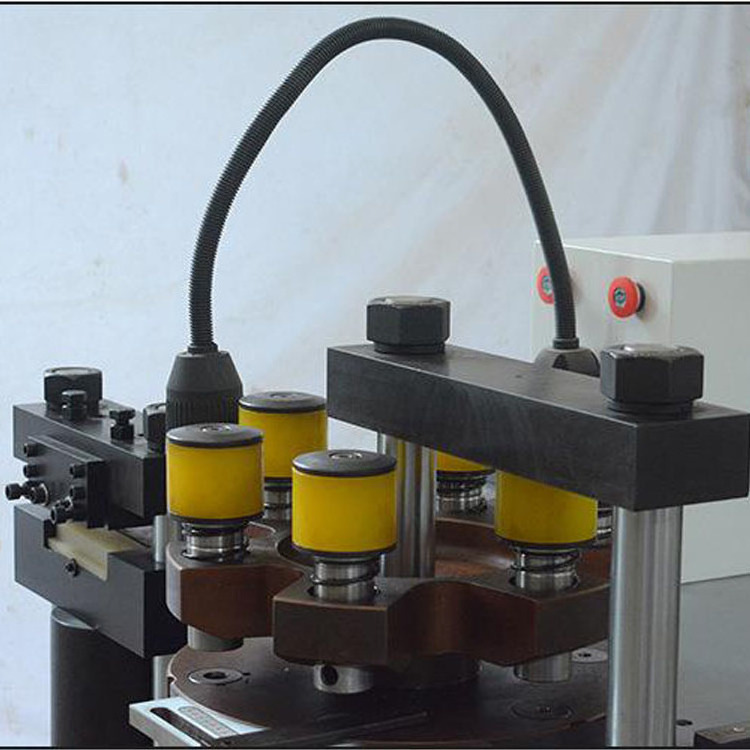

The punching unit adopts a six-die integral turntable, which increases the concentricity of the die and enhances the service life and efficiency.