- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

China

-

Brand Name:

-

Hongfa

-

Voltage:

-

220v / 380v

-

Dimension(L*W*H):

-

2060*1700*2560mm

-

Weight (KG):

-

4500 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Vibrating Frequency::

-

4500 rolls/minute

-

Cycle Time::

-

26 seconds

-

Applied Products::

-

Grass blocks, Slope blocks, Interlocking Blocks

-

Price:

-

low price

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Autoclaved aerated concrete block (AAC)

-

Brick Raw Material:

-

Crushed Stone, Sand, Cement, Dust and Coal Fly Ash, Slag

-

Production Capacity (Pieces/8 hours):

-

3400 pcs/8hours, 5760 pcs/8hours, 2560 pcs/8hours, 3000 sets/day

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

China

-

Brand Name:

-

Hongfa

-

Voltage:

-

220v / 380v

-

Dimension(L*W*H):

-

2060*1700*2560mm

-

Weight (KG):

-

4500 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Vibrating Frequency::

-

4500 rolls/minute

-

Cycle Time::

-

26 seconds

-

Applied Products::

-

Grass blocks, Slope blocks, Interlocking Blocks

-

Price:

-

low price

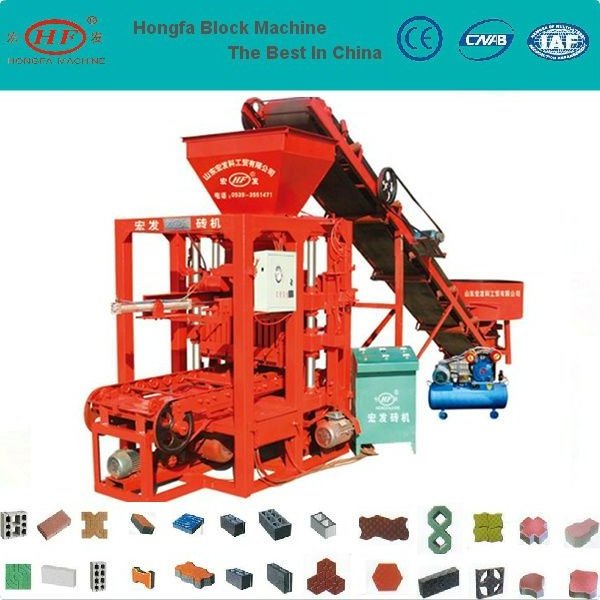

The Cheap QTJ4-26 Block Making Machine Specification

QTJ4-26 Brick Making Machine Capacity

What Are the QT4-26

Concrete Block Making Machine Features

?

Combining with German High-tech and Hongfa Technology, this advanced QT4-26 brick concrete making machine is superior to other block production machine in these aspects:

● Passing the strict quality inspection

- CE/SGS/ISO9001:2000

● With the best configuration

- Imported Control Panel

● With great performances

- With vibration case in the bottom, so can produce more densitive brick and motors not easy to burn

- Extremely proving the stability

- Upper mould moving and raw materials released handle by control box

- Effectively to solve the problems of system halted, holdup, weak pressure, motors burning and consumption in the block machine industry.

Advantages of QT4-26 Block Making Machine to Produce Concrete Brick

● High Density

Designed with particular storage and material system which insure the feeding accuracy and avoiding the effect of exterior material, this QT4-26 black making machine features high density.

Adopting frequency conversion motors and synchronization vibration to insure the products making average, and the vibration frequency can be adjusted randomly according to plastic character of various of raw materials.

The computer is of fault diagnosis system. Warning signal is propitious to eliminate the fault. Combine with long-distance controlling system, it can achieve scrutiny, controlling, as well as diagnosis.

Low frequency in feeding material and high frequency vibration makes the different materials to have an optimal vibration way.

The control system is equipped with complete logic control, production program, malfunction diagnosis system and remote control function. So it only needs a trained person for operation rather than a professional one.

The Block Making Process and Control System with Hongfa Brick or Block Making Machine

The Block or Brick Press Moulds to Make Blocks:

Raw Materials to Produce Block or Brick

Available Sizes and Thickness of Block or Brick Products

● Applied Block or Brick Products: concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edgers, kerbstones, grass blocks, slope blocks, interlocking blocks, etc.

● This Automatic Block Making Equipment or Brick Production Machine machine can make all kinds of bricks by changing mould, so we can make the mould according to customer's need .Below type of bricks just for your reference.

Only for your reference, these blocks or bricks can be customized according to customers' requirements.

With over 20 years' experience in R&D and manufacturing block making machine, fully-automatic brick production line, concrete pipe making machine, concrete mixing plant, as well as light weight EPS wall panel machine, Hongfa Heavy Machinery Co., Ltd. have gained much reputation by its high quality products which meet the ISO9001-2000 standard and with the certificates of CE, SGS, BV etc.

Owning over 67 patents (including invention and practical patents) and gaining "China Well-Known Trademark" honor, Hongfa Machinery is dedicated to providing high quality EPS light wight wall panel making machines to our customers.

Pre-Sales Service

* Free inquiry and consulting support.

* Analyze customers' needs and market prospect.

* View our Factory.

* Provide perfect solution to set up a factory to perform wall panel making machine operation.

After-Sales Service

* One year guarantee for wall panel making machine.

* Engineers available to service machinery overseas with EPS sandwich lightweight wall panel machine installation, training and maintenance.

* Supply free consultation and parts services.

Packing

Naked packing or stretch film packing or according to your requirements.

Delivery

Within 20~30 days after receiving deposit and moulds confirmation from buyer

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: 20~30 days after receipt of deposit and molds confirmation from Buyer.

Q: What is the product guarantee period ?

A: One year after installation finished at buyer's factory.

Q: What is your terms of payment ?

A: Payment: T/T or 100% by confirmed, irrevocable L/C at sight.

Note: The video of QT4-26 block making machine is available for you, please contact me now.

**Click "Send" as below to Get More Special Offers**

Contact: Yuki Yang

Skype: yukiyang08

Mob (Whatsapp): 0086-18378813711

Tel: 0086-0771-5672282

Fax: 0086-0771-6036901

Web: http://www.gxhongfa.cn

Company: Guangxi Hongfa Heavy Machinery Co., Ltd. (Manufacturer)

Add: Yiling Yan Industrial Centralized Zone, Nanning City, Guangxi Province, China