- Product Details

- {{item.text}}

Quick Details

-

Frequency:

-

600 (times / minute)

-

Weight:

-

60

-

Name:

-

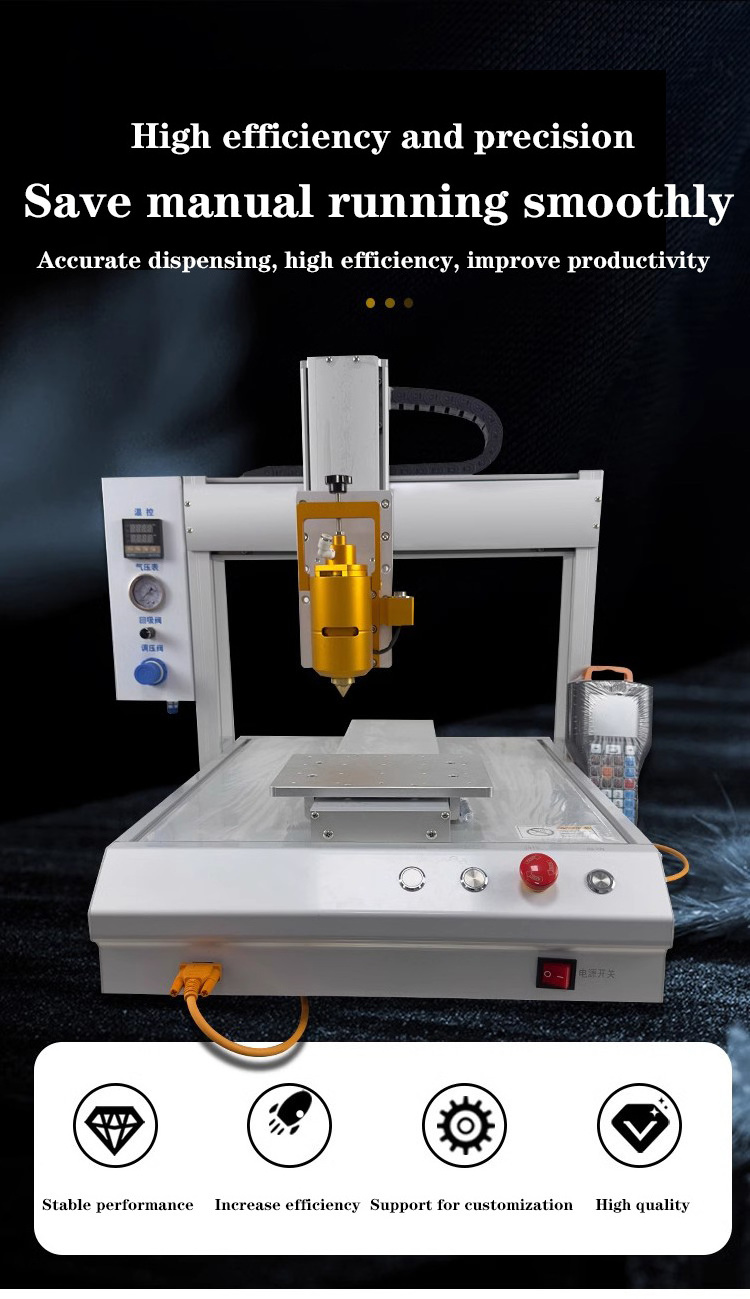

glue dispensing robot machine

-

humidity:

-

10-90%

-

temprature:

-

-10-40Celsius

-

moving:

-

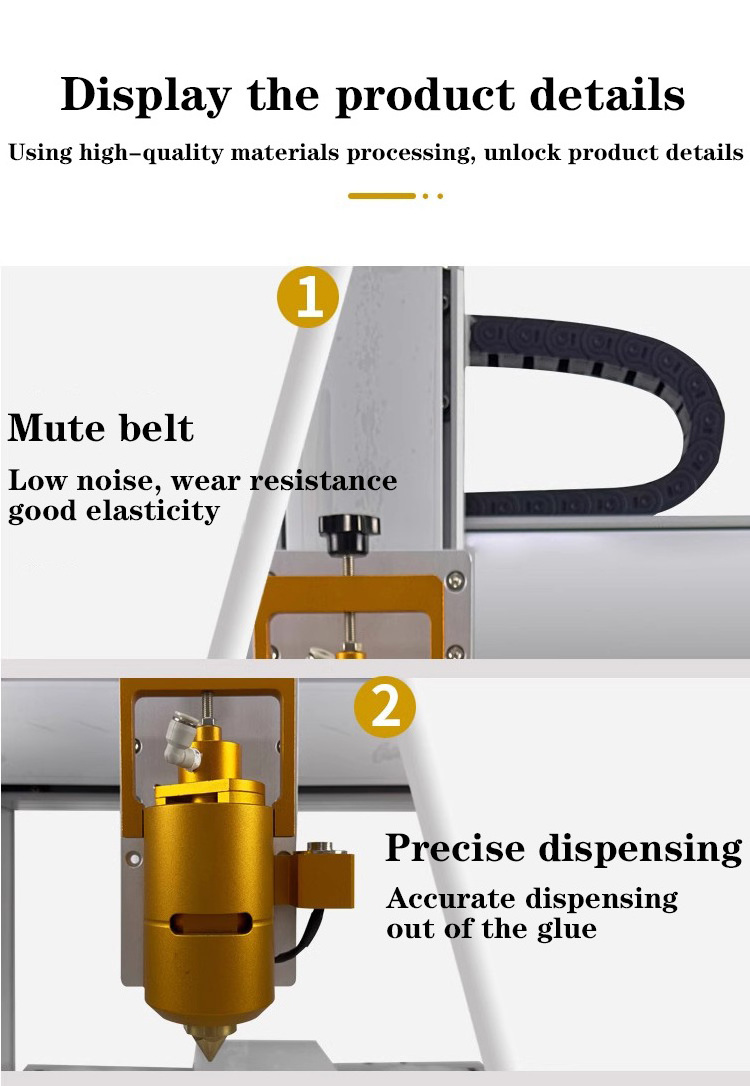

synchro belt or wire rod

-

Control Panel:

-

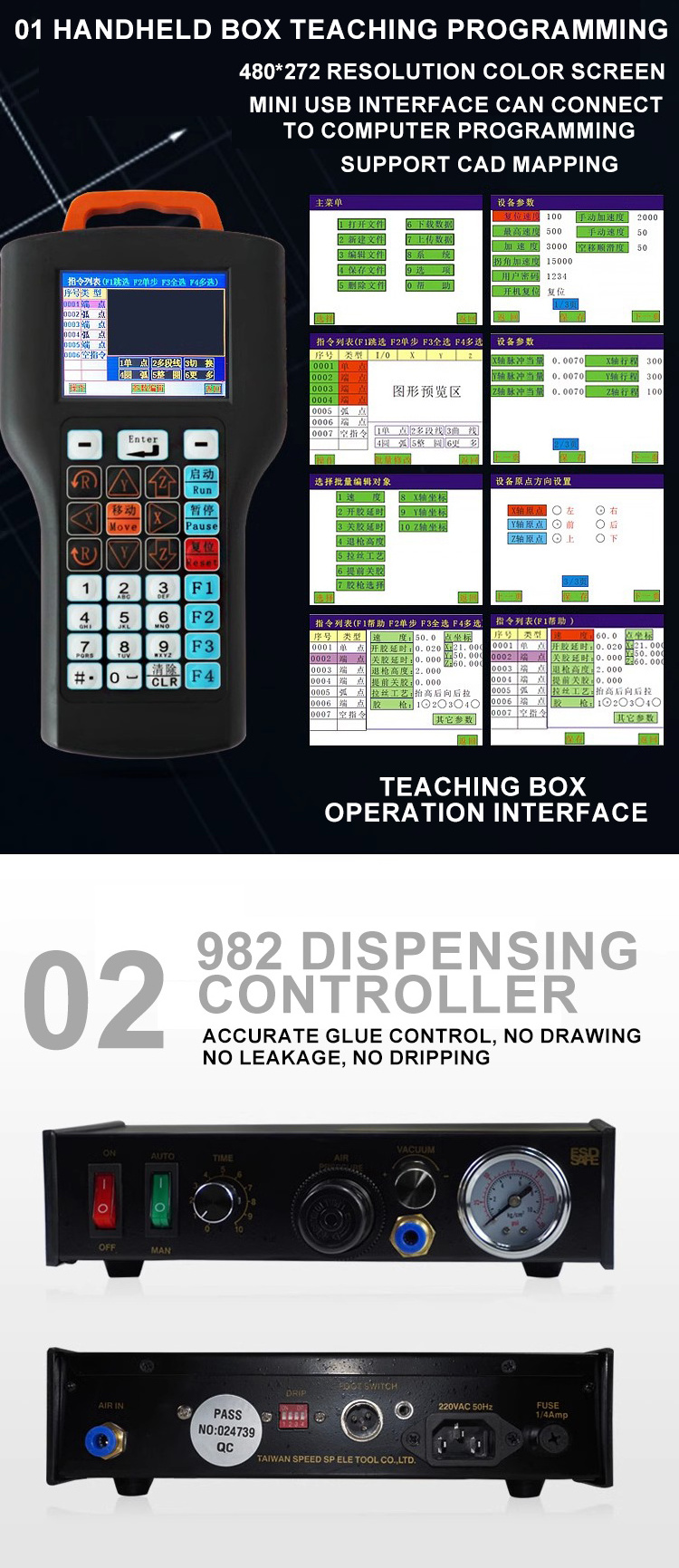

Teach pendant

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

YDY

-

Weight (KG):

-

60

-

Frequency:

-

600 (times / minute)

-

Weight:

-

60

-

Name:

-

glue dispensing robot machine

-

humidity:

-

10-90%

-

temprature:

-

-10-40Celsius

-

moving:

-

synchro belt or wire rod

-

Control Panel:

-

Teach pendant

Hot Searches