- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Leizhan

-

Voltage:

-

380v / 450v

-

Power:

-

300kw

-

Dimension(L*W*H):

-

As design

-

Weight:

-

1200 kg

-

Product name:

-

Machine to recycle cardboard

-

Raw material:

-

Waste carton paper, recycled paper, wood pulp

-

Trimmed Width:

-

1575-5800mm

-

Output paper:

-

Corrugated paper, fluting paper

-

Basis weight:

-

80-220g/m2

-

Application:

-

Paper Industry, Paper Factory

-

Experience:

-

Since 1980

-

Keyword:

-

Cardboard recycling machine

-

Usage:

-

Paper mill

-

Function:

-

Paper making machine

Quick Details

-

Production Capacity:

-

20-500 t/d

-

Product Type:

-

Cardboard recycling machine

-

Processing Type:

-

Paper making machine

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Leizhan

-

Voltage:

-

380v / 450v

-

Power:

-

300kw

-

Dimension(L*W*H):

-

As design

-

Weight:

-

1200 kg

-

Product name:

-

Machine to recycle cardboard

-

Raw material:

-

Waste carton paper, recycled paper, wood pulp

-

Trimmed Width:

-

1575-5800mm

-

Output paper:

-

Corrugated paper, fluting paper

-

Basis weight:

-

80-220g/m2

-

Application:

-

Paper Industry, Paper Factory

-

Experience:

-

Since 1980

-

Keyword:

-

Cardboard recycling machine

-

Usage:

-

Paper mill

-

Function:

-

Paper making machine

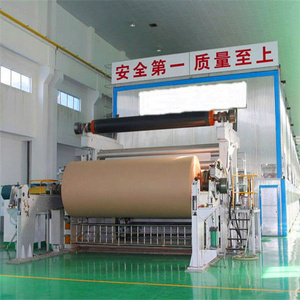

Corrugated Carton Box Base Paper Roll Making Machine/Cardboard Recycling Machine

Paper grades: corrugated paper

Raw material: waste carton, waste paper, wood pulp

Basis weight range: 80-220g/m²

Production capacity: 20-500 t/d

Trimmed width: 1575-5800mm

Working speed: 100-800m/min

Mill power supply: 380Volts, 50 Hz

Specification:

| Machine type | Cardboard recycling machine |

| Production capacity | 30-750t/d |

| Trimmed width | 1880-5800mm |

| Raw material | Waste paper, recycled paper, wood pulp |

| Basis weight | 60-200gsm |

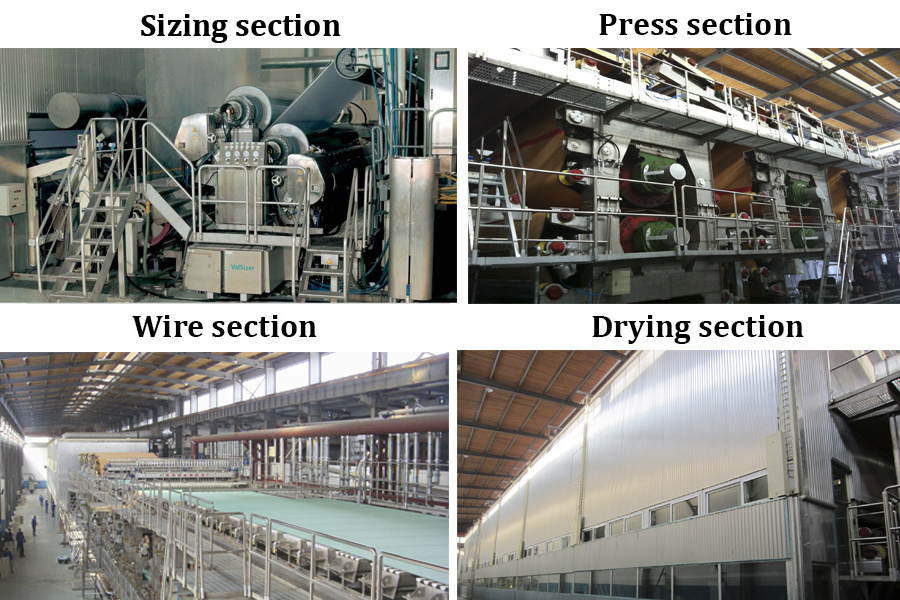

This paper making machine mainly used in the manufacture of corruagted paper, fluting paper, etc. The paper making machine is composed of wire section, press section, drying section, sizing section, reeling section, transmission section, foundation section, steam cover section, electric control section, lubrication section, paper rope system and so on.

The paper making machine uses raw material of waste paper pulp or other kinds of pulp to make new well selling paper.

Final product corrugated paper

Process Flow Diagram

Raw materials (waste paper)——chain conveyor——pulper——hign density cleaner——pressure screen——fiber separator——reject separator ——low density cleaner——inflow pressure screen——paper making machine——the big finished jumbo roll paper

Spare parts of paper making machine:

Installation

Control System

Adopt advanced computer programming technology.

How to Maintained

Warranty: 12 months from the date of last major dispatch for manufacturing defects.

Corrugated paper making machine is one of the most commonly used equipment at present corrugated paper processing, is also a kraft paper processing business people choose up a corrugated paper processing equipment, not only on the choice of raw materials have advantages, but also from a certain extent, the increase production and reduce the loss of paper. corrugated paper product machine