- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1.83*2.2*2m

-

Weight:

-

2000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

vertical:

-

press

-

zone:

-

electric

-

efficiency:

-

high

-

nominal mold lock force:

-

100ton, 160ton, 200ton and etc

-

motor power:

-

4kw, 6.2kw or others

-

type:

-

rubber silicone toy making machine

-

block stroke:

-

300mm, 400mm, 500mm

-

Max. distance of thermo-plate:

-

300mm, 400mm, 500mm

-

Power(W):

-

380v

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

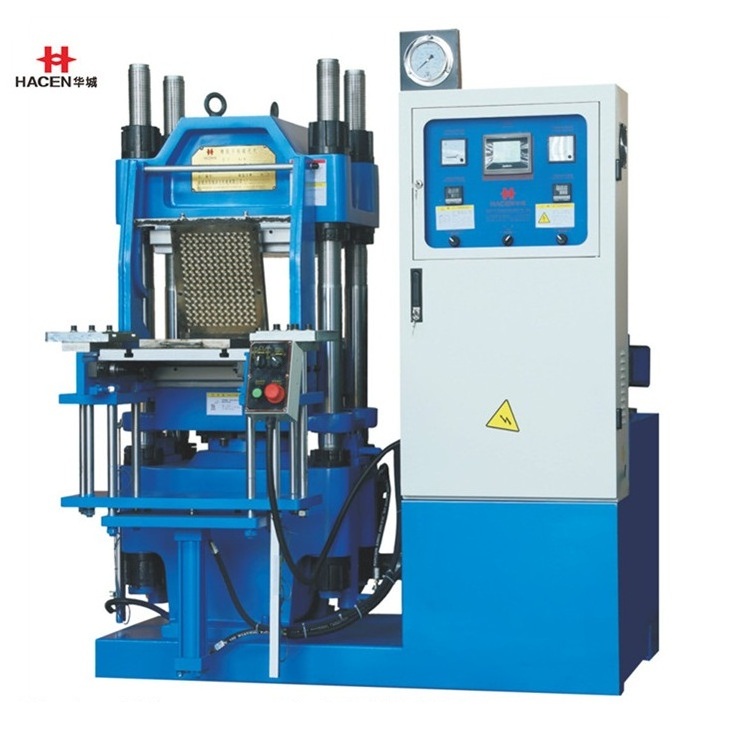

Brand Name:

-

Huacheng

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

1.83*2.2*2m

-

Weight:

-

2000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

vertical:

-

press

-

zone:

-

electric

-

efficiency:

-

high

-

nominal mold lock force:

-

100ton, 160ton, 200ton and etc

-

motor power:

-

4kw, 6.2kw or others

-

type:

-

rubber silicone toy making machine

-

block stroke:

-

300mm, 400mm, 500mm

-

Max. distance of thermo-plate:

-

300mm, 400mm, 500mm

-

Power(W):

-

380v

Product Description

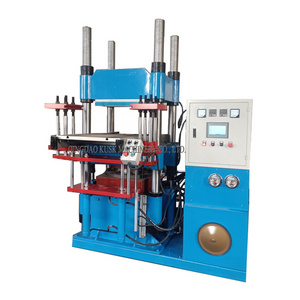

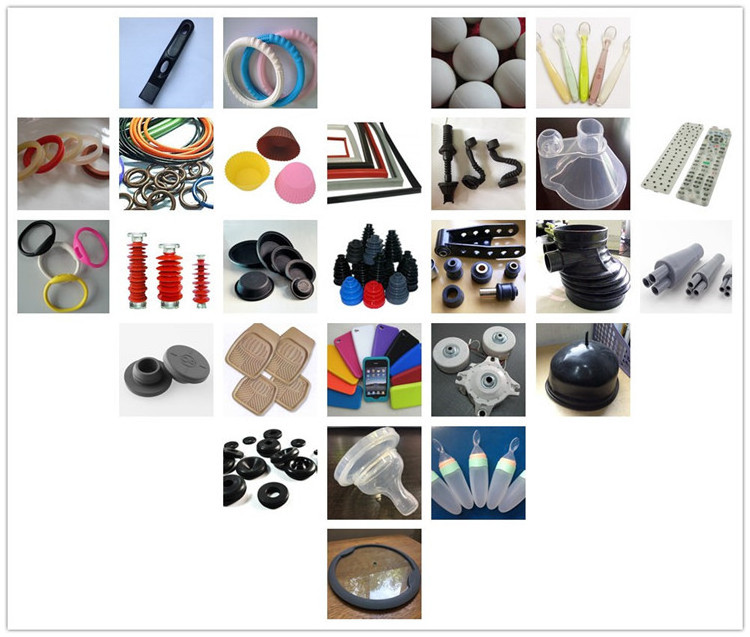

XZB series rubber transfer molding machine is suitable for injection and molding all kinds of rubber and silicone products. It is mostly suitable for high quality requiremets, like phone case, seal, gromment, gasket and etc.

Product Feature

1. Fast-open mold features high production efficiency and slow locking to protect the mold;

2. Automatic move-in-and-out and ejecting units allows low labor intensity;

3. Conventional valve and proportional valve are optional; advanced and rational oil-way configuration is energy saving;

4. Electric system adopts PLC and touch screen man-machine interaction.

5. 2RT/3RT/4RT for option;

6. Single machine and double machine for option; Operated:

7. Two choices fnr central mold-transfer and back toward mold-transfer

2. Automatic move-in-and-out and ejecting units allows low labor intensity;

3. Conventional valve and proportional valve are optional; advanced and rational oil-way configuration is energy saving;

4. Electric system adopts PLC and touch screen man-machine interaction.

5. 2RT/3RT/4RT for option;

6. Single machine and double machine for option; Operated:

7. Two choices fnr central mold-transfer and back toward mold-transfer

Detailed Images

Product Paramenters

|

Item

|

Unit

|

XLB-Y100

|

XLB-Y100B

|

XLB-Y100A

|

XLB-Y160

|

XLB-Y200

|

XLB-Y200

|

|

Mold-locking force

|

kn

|

1000

|

1000

|

1000

|

1600

|

2000

|

2000

|

|

Max. working pressure

|

Mpa

|

21

|

21

|

21

|

21

|

21

|

21

|

|

Clamp stroke

|

mm

|

300

|

300

|

300

|

300

|

250

|

250

|

|

Heat plate size

|

mm

|

420*420

|

450*450

|

500*500

|

520*540

|

520*540

|

600*600

|

|

Max. opening

|

mm

|

420

|

420

|

420

|

420

|

420

|

420

|

|

Motor power

|

Kw

|

4

|

4

|

4

|

5.5

|

5.5

|

5.5

|

|

Item

|

Unit

|

XLB-Y250

|

XLB-Y300

|

XLB-Y400A

|

XLB-Y400B

|

XLB-Y500

|

XLB-Y600

|

|

Mold-locking force

|

Kn

|

2500

|

3000

|

4000

|

4000

|

5000

|

6000

|

|

Mold-locking force

|

Mpa

|

21

|

21

|

21

|

21

|

21

|

21

|

|

Clamp stroke

|

mm

|

250

|

250

|

400

|

500

|

500

|

500

|

|

Heat plate size

|

mm

|

600*600

650*600

|

650*650

|

800*800

|

1000*1000

|

1000*1000

|

1200

*1200

|

|

Max. opening

|

mm

|

420

|

420

|

700

|

700

|

700

|

800

|

|

Motor power

|

Kn

|

7.5

|

7.5

|

11

|

11

|

15

|

15

|

Recommend Products

Our Honor

Factory overview

FAQ

Q

: What’s requipments do you have?

A

: Our company specialized in Thermosetting material molding, manufacture rubber silicone molding machine, injection molding machine, vacuum press machine, transfer molding machyine, BMC injection molding machine, LSR injection molding machine.

Q

: How long has your company been established?

A

: Our company established in 1992.

Q

: What’s the warranty of your machine?

A

: About one year.

Q

: What’s the delivery time of your machine?

A

; 10-60 work days

Q

: Which countries have you exported?

A

: We have export to many ccountries, Russia, Ukraine, Turkey, Pakistan, South Afria, Egypt, Poland, Germany, Korea, USA, Brazil ,Peru, Mexico, Indonesia, India, Vietnam, Tailand...

Q

: How about the after-sale service?

A

: We provide them free training so that they can use and maintain the machine independently.

We will answer customer’s questions on technology in time. If needed, we will offer on-site guidance. We can provide free technical guidance if customers need new equipment.

Service

Pre-sale service:

We can provide the good technology and experience, to help the customer manufacture the good products and give the good suggestion.

In-sale service:

Detailed design of lay-out that is the position of procession.

Technological information of provided products.

Schedule about design, manufacturing and installation.

Working & producing progression

Training curse for the technician so that the installation is safe and standard.

After-sale service:

For customers buying our products, we provide them free training so that they can use and maintain the machine independently.

We can provide the good technology and experience, to help the customer manufacture the good products and give the good suggestion.

In-sale service:

Detailed design of lay-out that is the position of procession.

Technological information of provided products.

Schedule about design, manufacturing and installation.

Working & producing progression

Training curse for the technician so that the installation is safe and standard.

After-sale service:

For customers buying our products, we provide them free training so that they can use and maintain the machine independently.

Contact Us

Contactor: Ms.Tiffi Shen

Mail: sales1@hc-machine.com

Wechat/Whatsapp:86-15867347287

Address:No.28, Shunke Road, Yangming Science & Technology IndustrialZone, Yuyao, Zhejiang, 315400, China

Hot Searches