- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

according to layout

-

Power (kW):

-

customized

-

Weight:

-

4000

-

Screw diameter (mm):

-

85-200

-

Screw Speed (rpm):

-

1 - 200 rpm

-

Application:

-

Producing Clean Plastic Pellets

-

Material:

-

PE PP PLA Film

-

Service system:

-

Arrange Engineer

-

Pelletizing type:

-

Water Ring Pelletizing

-

Capacity:

-

150-1000kg/h

-

Inverter:

-

ABB

-

Motor:

-

SIEMENS Brand

-

Screw Material:

-

38CrMoA1A

-

Configuration:

-

Singe Screw Extruder

-

Final product:

-

Small Plastic Pellet

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Output (kg/h):

-

150 - 1000 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Mooge

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

according to layout

-

Power (kW):

-

customized

-

Weight:

-

4000

-

Screw diameter (mm):

-

85-200

-

Screw Speed (rpm):

-

1 - 200 rpm

-

Application:

-

Producing Clean Plastic Pellets

-

Material:

-

PE PP PLA Film

-

Service system:

-

Arrange Engineer

-

Pelletizing type:

-

Water Ring Pelletizing

-

Capacity:

-

150-1000kg/h

-

Inverter:

-

ABB

-

Motor:

-

SIEMENS Brand

-

Screw Material:

-

38CrMoA1A

-

Configuration:

-

Singe Screw Extruder

-

Final product:

-

Small Plastic Pellet

-

Marketing Type:

-

Ordinary Product

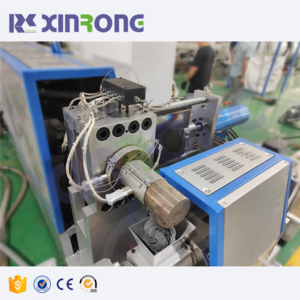

Film/Woven Bags Pelletizing Line

♥HDPE PP Granule Die Face Cutting Machine♥

HDPE PP granule die face cutting machine has two kinds of type. The RDS-Series plastic granulator machine is single stage plastic pelletizing machine with die face cutting system used for clean industrial waste PE film, PP shopping bags. What's more, the RSS-Series plastic granulator machine is double stages plastic pelletizing machine with die face cutting system used for washing recycled PE film, PE shopping bags material. With double stage it work more stable, produce more clean and more density granules.

Product Specification

RDS Series Single Stage Compacting Die-Face Cutting Pelletizing Line (For PE Film, PE Bags, PLA Film)

|

Model

|

Screw Diameter

|

Screw L/D

|

Main Motor Power

|

Capacity

|

|

RDS-SJ85

|

85mm

|

28-33:1

|

55KW

|

150-200kg/hr

|

|

RDS-SJ100

|

100mm

|

28-33:1

|

75KW

|

200-300kg/hr

|

|

RDS-SJ130

|

130mm

|

28-33:1

|

90KW

|

300-400kg/hr

|

|

RDS-SJ150

|

150mm

|

28-33:1

|

110KW

|

400-500kg/hr

|

|

RDS-SJ160

|

160mm

|

28-33:1

|

132KW

|

500-600kg/hr

|

|

RDS-SJ180

|

180mm

|

28-33:1

|

160KW

|

600-800kg/hr

|

|

RDS-SJ200

|

200mm

|

28-33:1

|

200KW

|

800-1000kg/hr

|

RSS Series Double Stage Compacting Die-Face Cutting Pelletizing Line (For PE Film,

PE Bags, PLA Film

)

|

Model

|

Screw Diameter

|

Screw L/D

|

Main Motor Power

|

Capacity

|

|

RSS-SJ85

|

85mm

|

28-33:1

|

55KW

|

150-200kg/hr

|

|

RSS-SJ100

|

100mm

|

28-33:1

|

75KW

|

200-300kg/hr

|

|

RSS-SJ130

|

130mm

|

28-33:1

|

90KW

|

300-400kg/hr

|

|

RSS-SJ150

|

150mm

|

28-33:1

|

110KW

|

400-500kg/hr

|

|

RSS-SJ160

|

160mm

|

28-33:1

|

132KW

|

500-600kg/hr

|

|

RSS-SJ180

|

180mm

|

28-33:1

|

160KW

|

600-800kg/hr

|

|

RSS-SJ200

|

200mm

|

28-33:1

|

200KW

|

800-1000kg/hr

|

FEATURES AT A GLANCE

Compacting Force Feeder

Compacting hopper opening by hydraulic system.

With glass window and light to check inside working.

With glass window and light to check inside working.

Barrel base with the water cooling system controlled by magnetic valve by temperature

The barrel touched material all made by stainless steel.

The barrel touched material all made by stainless steel.

Single Screw Extruder

Single screw Extruder made by sturdy frame, heavy. No vibrating when machine running;

The whole frame where installed the gearbox, motor and screw has done the milling working.

The frame is build up by the square tube and thick steel on top.

The whole frame where installed the gearbox, motor and screw has done the milling working.

The frame is build up by the square tube and thick steel on top.

Hydraulic Screen Changer

Double position board model

Board made by 38CrMnAl with forging, heating treatment won’t deform after heating using.

Board made by 38CrMnAl with forging, heating treatment won’t deform after heating using.

Vertical Die Face Cutting System

Cutting speed adjust by inverter

Inverter brand: DELTA of Taiwan

Inverter brand: DELTA of Taiwan

Blade made by SKD-11 steel

Die mold Made by the 38CrMoALA material with forging treatment, surface been nitriding treatment and buffing.

Die mold Made by the 38CrMoALA material with forging treatment, surface been nitriding treatment and buffing.

Product Photos

Optional: Semi-automatic Metal Detector

Customized Degassing Die Head

Hydraulic Power Station for vacuum degassing unit

Die Head for PE Film

Optional: Horizontal Die Face Cutting

Vertical dewatering machine

Raw Material: Clean PE Film Flakes

FInal Product: PE Pellets

Customer Photos

RDS-SJ85 in Argentina

RSS-SJ120 in Netherlands

Related Product

PP Film/Woven Bags Strand Cooling Pelletizing Line

PE/PP Film Woven Bags Washing Line

Product Packaging

Our Service

Service Before Sale

1. 24 hours online. Your inquiry will be quick reply by email.

Also can go through all questions with you by any online chatting tools (Wechat, Whatsapp, Skype, Viber, QQ, TradeManager )

2. Professionally and patiently introduction, details pictures and working video to show machine

Also can go through all questions with you by any online chatting tools (Wechat, Whatsapp, Skype, Viber, QQ, TradeManager )

2. Professionally and patiently introduction, details pictures and working video to show machine

Service On Sale

1. Test every machine and inspect the machine seriously.

2. Send the machine picture which you order, then packing it with standard export wooden box after you confirm the machine is ok.

3. Delivery: If ship by sea .after delivery to seaport. Will tell you the shipping time and arrival time. Finally, send all

original documents to you by Express For Free.

If delivery it by Express to your door (DHL, TNT, Fedex, etc) or by air to your airport, Or logistic to the warehouse which you

request. We will tell you the tracking number after delivery.

2. Send the machine picture which you order, then packing it with standard export wooden box after you confirm the machine is ok.

3. Delivery: If ship by sea .after delivery to seaport. Will tell you the shipping time and arrival time. Finally, send all

original documents to you by Express For Free.

If delivery it by Express to your door (DHL, TNT, Fedex, etc) or by air to your airport, Or logistic to the warehouse which you

request. We will tell you the tracking number after delivery.

Service After Sale

1. Free insurance for goods

2. 24 hours online to solve any problem. Supply you English manual book and technical support, maintain and install video to help you solve the problem, or dispatch worker to your factory.

2. 24 hours online to solve any problem. Supply you English manual book and technical support, maintain and install video to help you solve the problem, or dispatch worker to your factory.

Hot Searches