1. Wear resistant, long service life.

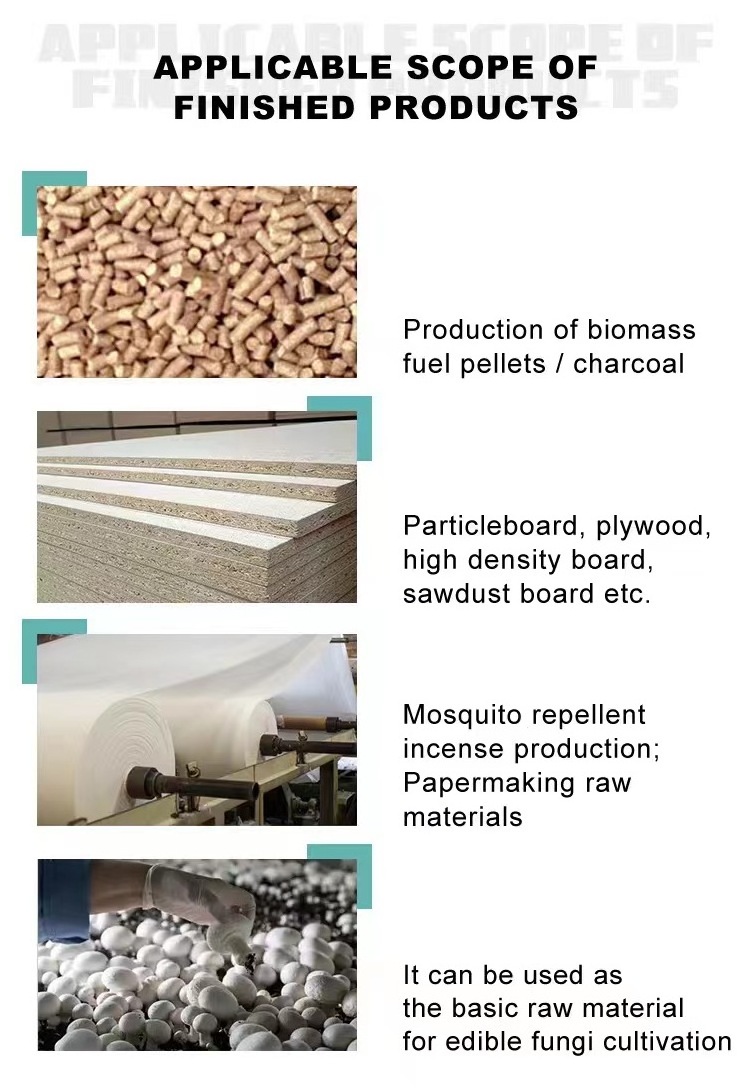

2.

Dual feeding ports allow for simultaneous feeding of wood and straw.

3. Suitable for all seasons, is not restricted by climate.

4.

One machine for multiple purposes.

5.

Simple design,easy to operate and maintain.

6.

Save time and effort.