- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

MG

-

Voltage:

-

220-440v

-

Power:

-

40-60kw

-

Dimension(L*W*H):

-

6000*3000*3200mm

-

Weight:

-

10000 kg

-

Features:

-

Long Service Life

-

Capacity:

-

6-8 T/h

-

Batching and weighting:

-

Automatic+manual System

-

Name:

-

6-8T dry mix powder mortar production line

-

Mixer Type:

-

Double Paddle Shafts Mixer

-

Mixing time:

-

3-5mins/batch

-

Packing System:

-

Valve Packing Machine

-

Packaging:

-

15-50kg/bag

-

Raw material:

-

Sand Cement Additives

-

Worker required:

-

2-3 Person

-

Certification:

-

CCC,ISO,CE,BV

Quick Details

-

Marketing Type:

-

Hot Product 2022

-

Application:

-

Dry Mortar Mixer

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

MG

-

Voltage:

-

220-440v

-

Power:

-

40-60kw

-

Dimension(L*W*H):

-

6000*3000*3200mm

-

Weight:

-

10000 kg

-

Features:

-

Long Service Life

-

Capacity:

-

6-8 T/h

-

Batching and weighting:

-

Automatic+manual System

-

Name:

-

6-8T dry mix powder mortar production line

-

Mixer Type:

-

Double Paddle Shafts Mixer

-

Mixing time:

-

3-5mins/batch

-

Packing System:

-

Valve Packing Machine

-

Packaging:

-

15-50kg/bag

-

Raw material:

-

Sand Cement Additives

-

Worker required:

-

2-3 Person

-

Certification:

-

CCC,ISO,CE,BV

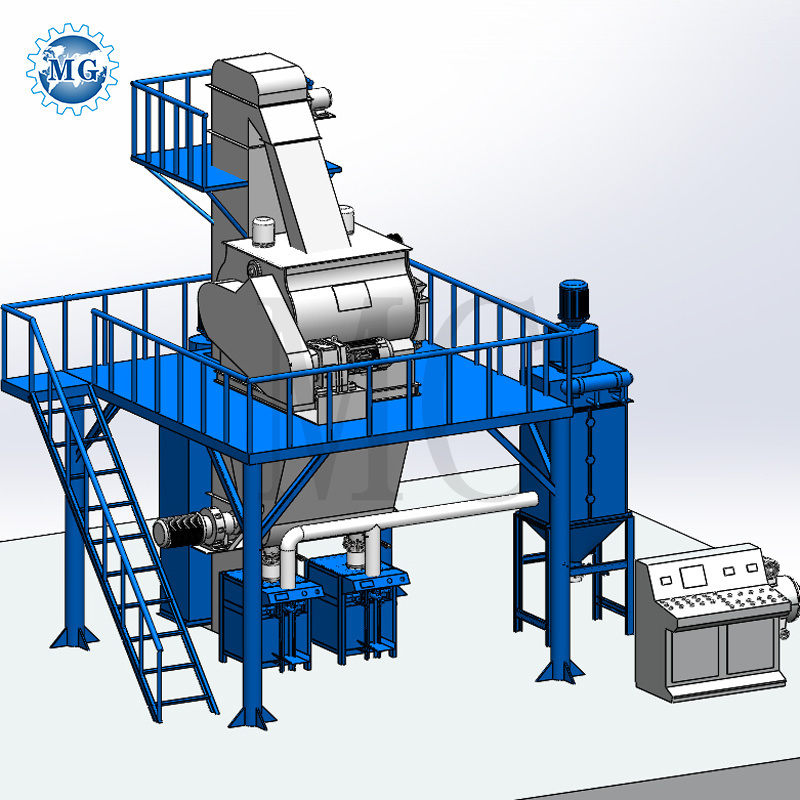

Product Overview

Energy Saving Semi-automatic Dry Mortar Mixing Plant

MGDM-3.1 semi-automatic dry mortar mixing

equipment

also called

energy-saving dry mortar mixing line,

dry mortar mixing machine. Which can feed various materials into the bin, under the automatic control system, this production line can realize automation in collecting, feeding, filling and packing. It is the

ideal selection for set up a dry mortar factory with reasonable price and quick refund.

This plant

area occupation is around 25-35 ㎡, equipment height: 6m, worker required: 3–4 person,

production capacity: 6-8T/H It

is the ideal selection for medium enterprises who want set a dry mortar factory at a reasonable price with a quick profits. and

it is the basic design for upgrade into full automatic Dry Mortar Mixing Production Line.

Working principle of B

lending Equipment for Gypsum Powder/Tile Grout/Wall Putty

First, the raw material feeding from the bottom of the feeding hopper according to mixture ratio.

Second, the equipment can realize automatic feeding, automatic mixing and automatic rationing and packaging

through the action of control system,

.

Besides, the equipment adopts high-efficiency biaxial agravic mixer as its main mixing system. Requiring little investment and small area but with good efficiency, it is an ideal one for small and medium-sized company.

|

Model

|

Out Put

|

Occupied Area

|

Equipment Height

|

Manpower

|

Batching and Packaging

|

|

Simple Type

|

3-4t/h

|

20 ㎡

|

3-4m

|

2-3 Person

|

Manual Batching

Automatic Packaging |

|

Semi-automatic Type

|

6-8t/h

|

50-60㎡

|

6-8m

|

3-4 Person

|

Manual Batching

Automatic Packaging |

|

Full Automatic Type

|

8-30t/h

|

60-100㎡

|

8-13m

|

3-4 Person

|

Automatic Batching

Automatic Packaging |

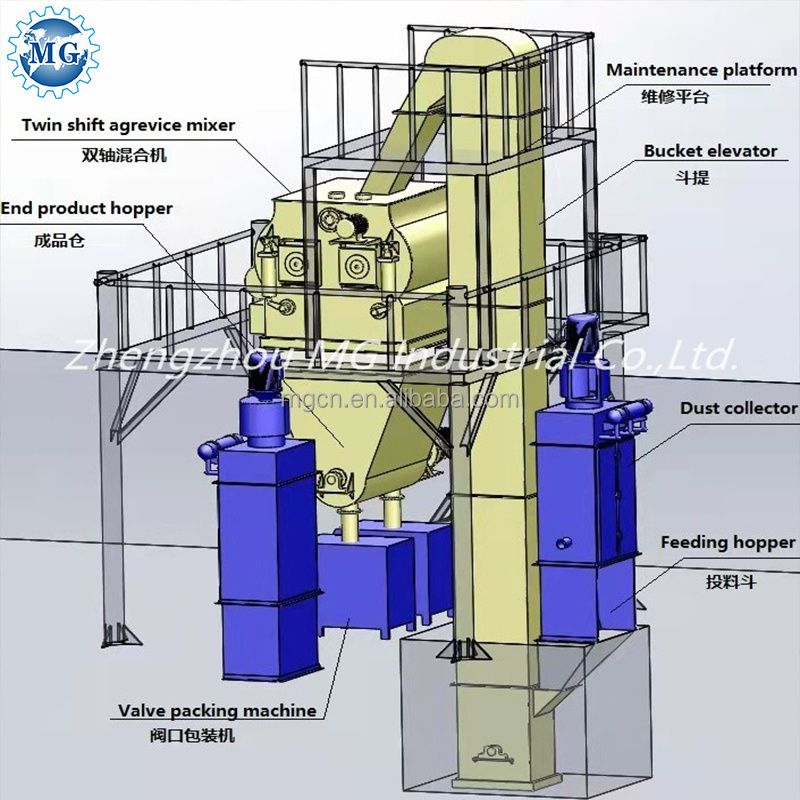

Product Configuration

Component of the Semi-automatic Dry Mortar Mixing Plant

The Semi-automatic Dry Mortar Mixing Plant includes a bucket elevator for the mixer, twin shaft mixer, finish product hopper, packing machine, impulse dust collector, air compressor, platform and steel structure, control cabinet, air circuit system.

Twin Shaft Mixer

2m³ with fly cutter

Finish Product Hopper

2m³ with second mixing

Valve Port Packing Machine

15-50 kg/bag adjustable

packing speed: 6s/bag

Impulse dust collector

12 cloths bags

Air Compressor

0.9 m³

Control Cabinet

Full set

Raw material of dry mortar:

1. Cementing material: cement, lime, plaster.

2. Aggregate: yellow sand, quartz sand, limestone, dolomite, expanded perlite etc.

3. Mineral admixture: industrial byproduct, industrial slag, fly ash, pozzolana, fine silica powder etc.

4. Water-retention and thickening material.

5. Chemical additives.

Application of MG automatic dry mortar blending machine:

The dry mortar production line can produce the following dry mortars:

Bonding mortar: Masonry mortar, wall and floor tile adhesive mortar, anchorage mortar etc.

Decoration mortar: Decorative plaster, inner and outer wall putty, colorful decoration mortar etc.

Protection mortar: Water-proof mortar, anti-corrosion mortar, self-leveling mortar, wear resistance mortar, thermal insulation mortar, sound insulation mortar, repair mortar, mildewproof mortar, shielding mortar etc.

Packaging & Delivery

Our Company

Zhengzhou MG industrial Co., Ltd, the leader of Full Automatic dry mortar blending equipment!

Zhengzhou MG Industrial Co,. Ltd, the leader in pre-mixed dry mortar mixing plant, providing you with new and refurbished building solutions over 80 countries around the world.

Zhengzhou MG was founded in 2000, located in the beautiful city of Zhengzhou, which is an integrated high-tech enterprise of R&D, production, sale and construction in dry mortar mixing equipment. We are an executive member of Chinese private Technology Promotion Committee and building materials Experts Association. As an National top rank building Mechanical Enterprise, we're certified by ISO9001 quality management system, and we honored to be the executive director of Henan Building Energy Conservation

Committee.

Our main products include dry mortar production line, thermal insulation mortar production line, sand dryer Plant, powder blending machine, concrete mixer, and others.

Successful Project

Project in Italy

Project in

Russia

Project in

Serbia

Project in Malaysia

Project in Egypt

Project in UAE

Related Products

Hot Searches