- Product Details

- {{item.text}}

Quick Details

-

Power:

-

7.5

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HACST

-

Dimension(L*W*H):

-

5600*2200*2200mm

-

Weight:

-

26000 KG

-

Other Name:

-

Refrigeration Evaporative Condenser

-

Coil Material:

-

SS304, SS316L, Galvanized

-

Casing Material:

-

SS304, SS316L, AZ Steel

-

Cooling Tower Coil Shape:

-

Round and Oval

-

Thickness of Coil:

-

1mm, 1.2mm, 1.5mm, 2mm

-

Removable Drift Eliminator:

-

PVC

-

Fills:

-

PVC

-

Type of Cooling Tower:

-

Counter Flow, Combined Flow, Cross Flow

-

Fan Type:

-

Axial Flow Fan

-

Pump Type:

-

Centrifugal Pump

Quick Details

-

Cooling Type:

-

Counter Flow

-

Material:

-

Metal

-

Voltage:

-

380V or others

-

Power:

-

7.5

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HACST

-

Dimension(L*W*H):

-

5600*2200*2200mm

-

Weight:

-

26000 KG

-

Other Name:

-

Refrigeration Evaporative Condenser

-

Coil Material:

-

SS304, SS316L, Galvanized

-

Casing Material:

-

SS304, SS316L, AZ Steel

-

Cooling Tower Coil Shape:

-

Round and Oval

-

Thickness of Coil:

-

1mm, 1.2mm, 1.5mm, 2mm

-

Removable Drift Eliminator:

-

PVC

-

Fills:

-

PVC

-

Type of Cooling Tower:

-

Counter Flow, Combined Flow, Cross Flow

-

Fan Type:

-

Axial Flow Fan

-

Pump Type:

-

Centrifugal Pump

Ammonia Refrigeration Cooling Evaporative Condenser for Mycom Compressor Cooling

Working Principle of evaporative condenser

For ZNX series combined flow evaporative condenser, the fresh air intakes from bottom air inlet, and will become saturated hot air mixed with spraying water as they flow in reverse direction. The heat will be exhausted out by fans , but the water will be collected to water basin for secondary spraying by its special designed drift eliminator. As no infill inside, ZNX series combined flow evaporative condenser has much space to enlarge its coil unit heat rejection area, more compact structure and requires less footprint.

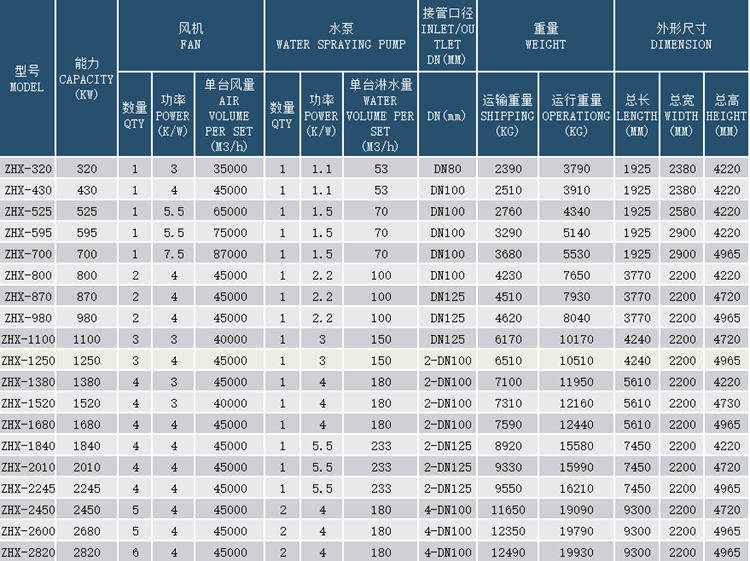

Technical Date for Ammonia Refrigeration Cooling Evaporative Condenser for Mycom Compressor Cooling

Details of ammonia refrigeration evaporative condenser

1. Coil material: Galvanized steel/stainless steel/red copper

2. Casing material: Al-Zn alloy coated steel sheet/stainless steel

3. Fan type: Axial flow type

4. Cooling tower fill: 100% original PVC material

5. Drift eliminator: Special designed anti-corrosion PVC

6. Water flow loss: Less than 0.005%

7. Maintenance: with access door and ladder

8. Noise Control: Low speed fan, noise damping

7. Fan & water pump motor: Siemens, WEG

8. Customization: Yes

| Evaporative condenser casing material | SS304, SS316L, AZ steel, FRP |

| Heat exchnage coil material | SS304, SS316L, galvanized |

| Coil tube thickness | 1mm, 1.2mm, 1.5mm, 2mm |

| Thickness of casing | 2mm, 3mm |

Production Process for evaporative condenser

Production Process for evaporative condenser

Application of evaporative condenser

Our evaporative condenser used for cold storages, food processing units, C.A stores, milk plants, Breweries, Bottling units, meat and fish plants, ice plants, chilling units and similar ammonia based industrial refrigeration jobs.