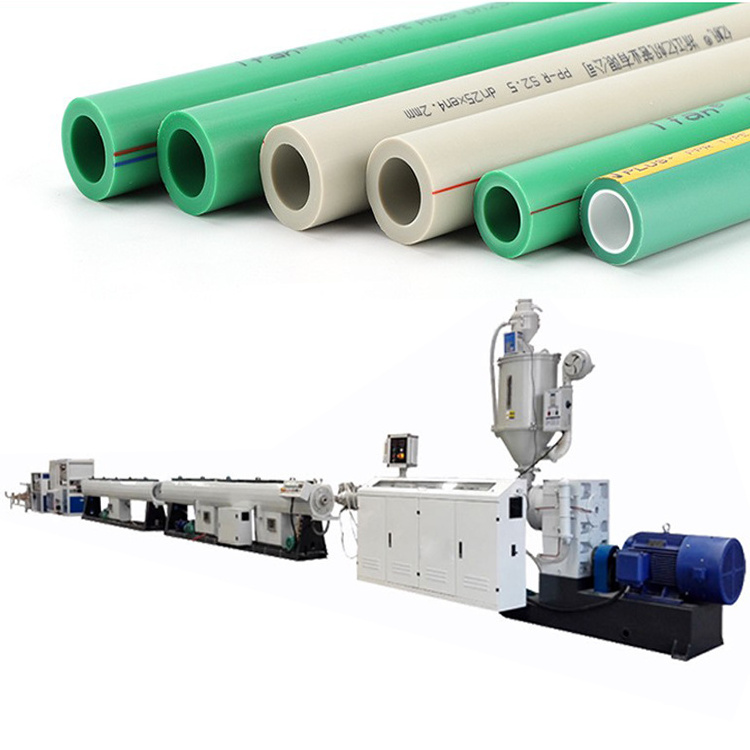

The number of layers and color of pipes determines the number of extruders.

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

VINA

-

Voltage:

-

380V/220V/440V

-

Dimension(L*W*H):

-

30000X1450X2800mm

-

Power (kW):

-

45

-

Weight:

-

10000 KG

-

Name:

-

Plastic pipe extruder

-

Raw material:

-

Plastic granules

-

Motor brand:

-

SIEMENS Brand

-

Inverter:

-

ABB Brand

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

33:1

-

Screw Speed (rpm):

-

120 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

VINA

-

Voltage:

-

380V/220V/440V

-

Dimension(L*W*H):

-

30000X1450X2800mm

-

Power (kW):

-

45

-

Weight:

-

10000 KG

-

Name:

-

Plastic pipe extruder

-

Raw material:

-

Plastic granules

-

Motor brand:

-

SIEMENS Brand

-

Inverter:

-

ABB Brand

Product Description

Features

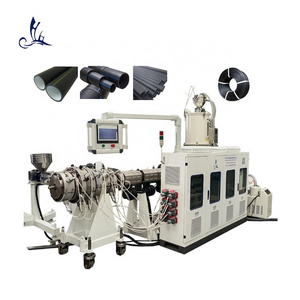

PPR series plastic pipe production line is mainly used for producing pipe of drinking water supplying etc. This machine consists of extruder, mould, vacuum calibration tank, haul off unit. Cutting unit, stacker, winder etc. The single screw extruder and haul off unit apply famous A/C frequency conversion speed regulation device, both vacuum pump and water pump apply famous brand. The haul-off unit includes two-claw type, three-claw type. Dust free cutting machine, saw blade cutting machine or planetary cutting machine can be applied, the cutting machine is controlled automatically with computer,the property of machine group is reliable.The production efficiency is high with special device. It can also produce PERT,PP, PE, ABS, PEX, Silicon core pipe 1-2-3-4-5 layers pipes etc. it has such advantages of simple operation, reliable performance etc. It has reached international advanced level.

|

MODEL

|

SJ-50

|

SJ-65

|

SJ-75

|

SJ-90

|

SJ-120

|

|

Speed of Screw Rotationl

|

20-90

|

20-120

|

20-120

|

20-120

|

20-120

|

|

Pipe Range(mm)

|

16-32

|

20-63-110

|

75-250

|

110-450

|

315-630

|

|

Power (kw)

|

22

|

45-75

|

55-110

|

90-160

|

160-200

|

|

Output(kg/h)

|

30-80

|

150-250

|

200-350

|

300-450

|

450-800

|

|

L/D Ratio

|

33

|

33

|

33

|

33

|

33

|

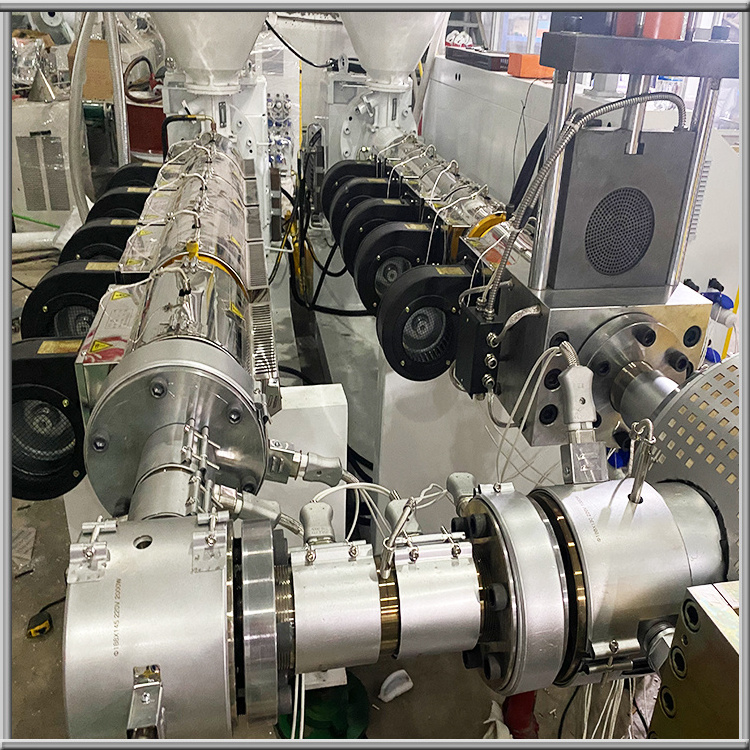

Detailed Images

Extruder

.

Mold

.

Preliminary shaping of pipes.

Color code extruder

.

Used for pipe wall color marking.

Vacuum calibration tank

.

Used for vacuum shaping of pipes.

Cooling water tank

.

For complete cooling of pipes.

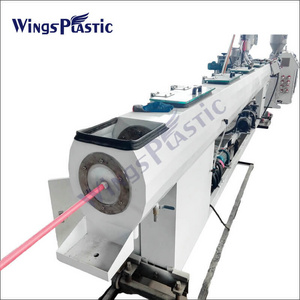

Fiber laser printer

.

Used for printing and editing pipeline information.

Hauling Off Machine

.

Used for uniform haul off of pipes.

Dust free cutting machine

.

The cutting port is flat and free of debris.

Pipe

stacker

.

Automatic stacking of pipes.

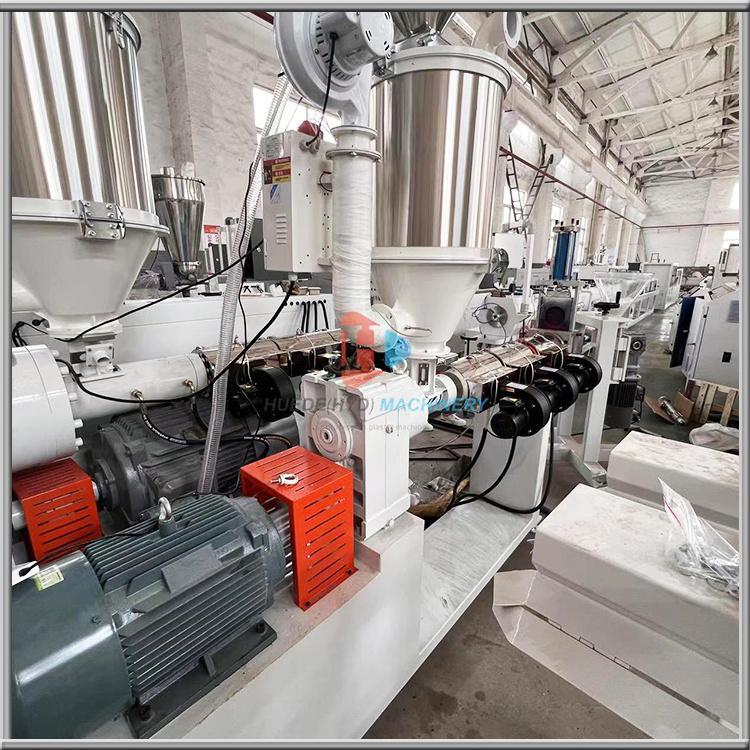

Screw barrel :

38CrMoAlA material, after nitriding and diffraction treatment, with a nitriding layer depth of ≥ 0.6mm, has sufficient strength, wear resistance, and corrosion resistance.

Barrier type screw, asymmetric slotted barrel design.

Gearbox :

Strong thrust bearing, high torque output; The gears are made of special alloys with hard tooth surfaces and processed by grinding technology. They are high-quality, high torque, and high-speed gearboxes, with low heat generation, low noise, and long service life.

Heater :

Fast heating, uniform heat dissipation, beautiful appearance, good insulation performance, and durability, suitable for high temperature and high power requirements.

Finish product

Hot Searches