- Product Details

- {{item.text}}

Quick Details

-

Model:

-

300/600/1000/1700/2000

-

Color:

-

your requirement

-

Type:

-

300/600/1000/1700/2000

-

Usage:

-

polishing nails mainly

-

Remove:

-

Nail Polish Remover Liquid

-

Certification:

-

ISO9001

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

GREENS

-

Weight (KG):

-

1800

-

Model:

-

300/600/1000/1700/2000

-

Color:

-

your requirement

-

Type:

-

300/600/1000/1700/2000

-

Usage:

-

polishing nails mainly

-

Remove:

-

Nail Polish Remover Liquid

-

Certification:

-

ISO9001

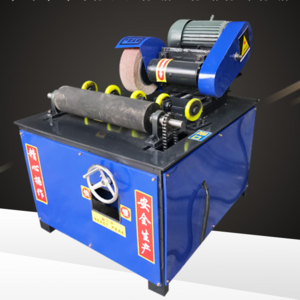

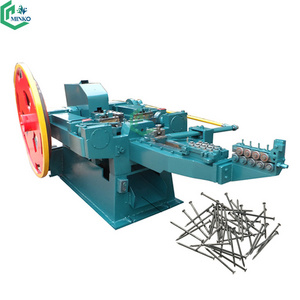

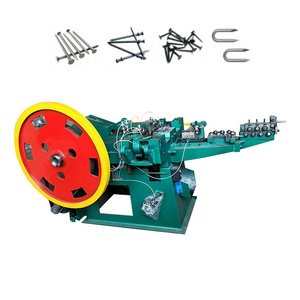

Automatic stainless steel wire nail buffing machine

We are manufacturer from Shijiazhuang of Hebei province near to Beijing .

This machine is mainly used to polish the surface rust of various kinds of nails .

Technical parameter of steel wire nail buffing machine

| Model | Capacity | Motor power | Dimension (mm) |

| 300 | 300KG | 2.2KW | 1700*1300*1500 |

| 600 | 600KG | 3KW | 2000*1300*1500 |

| 1000 | 1000KG | 4KW | 2400*1300*1500 |

| 1700 | 1700KG | 5.5KW | 3000*1500*1500 |

| 2000 | 2000KG | 7.5KW | 3200*1700*1700 |

Process of steel wire nail buffing machine

Step 1 ⇒ A dd about one kilogram kerosene into the burnishing barrel if you want to polish 400KG metal nails.

The machine should work for 1.5 hours so as to remove the rust, oil, oxide coatings, and drawing powder of nail surface.

Step 2 ⇒ Add about 500g sawdust into the barrel if your nails weight 400kg .

The machine should work for 15--20min but can not more than 30min to adsorb the dirty things away.

Step 3 ⇒ E quip with filter system to winnow dirty things away.

Step 4 ⇒ A dd 100g paraffin powder or paraffin sections into the polishing barrel if you want to polish 400kg nails .

The machine should work for 10min . The metal nails are coated with paraffin in order to prevent moisture.

If your city climate is too wet , you need to add more 500 gram sawdust into the barrel per ton nails.