- Product Details

- {{item.text}}

Quick Details

-

Roll Ratio(Front/Back):

-

1:1.25

-

Cooling Mode:

-

Water Cooling ( option)

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Qunlong

-

Voltage:

-

220V-380V

-

Dimension(L*W*H):

-

1500*700*1100mm

-

Year:

-

2021

-

Power (kW):

-

3

-

Weight (KG):

-

700 KG

-

Applicable Industries:

-

Plastic Rubber

-

Roller Pitch(mm):

-

0-8

-

Rear Rolling Speed (rev/min):

-

21.5

-

Primary yield ( kg ):

-

5-8

-

Reducer model:

-

ZQ250

-

Rotation speed (rev/min):

-

960

Quick Details

-

Diameter of Roll(mm):

-

150 mm

-

Rotation Speed of Front Roll(rpm):

-

1 - 18 rpm

-

Length of Roll(mm):

-

500 mm

-

Roll Ratio(Front/Back):

-

1:1.25

-

Cooling Mode:

-

Water Cooling ( option)

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Qunlong

-

Voltage:

-

220V-380V

-

Dimension(L*W*H):

-

1500*700*1100mm

-

Year:

-

2021

-

Power (kW):

-

3

-

Weight (KG):

-

700 KG

-

Applicable Industries:

-

Plastic Rubber

-

Roller Pitch(mm):

-

0-8

-

Rear Rolling Speed (rev/min):

-

21.5

-

Primary yield ( kg ):

-

5-8

-

Reducer model:

-

ZQ250

-

Rotation speed (rev/min):

-

960

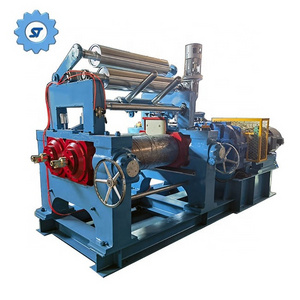

Laboratory 6 Inch Plastics Granules Silicone Rubber Compound Mixer Machine Two Rolls Mixing Mill

Working Principle

The open mill is a kind of open plastic material batch mixing equipment with adjustable gap between rollers composed of two parallel rollers.

Its main function is to mix and plasticize the mixed uniform raw materials, and provide the mixed plasticized uniform molten material for the calender

. In the process of rubber mixing, the opener mainly relies on two relatively rotary drums to produce extrusion and shear effects on the rubber. After many times of kneading and mixing, the mixing process will also be accompanied by chemical action, breaking the macromolecular chain inside the rubber, so that various components in the rubber are mixed and dispersed uniformly, and finally the purpose of rubber mixing is achieved.

Application Scope

The function of this machine is to mix raw materials and additives evenly. In order to meet the requirements of customers and make the products meet the quality and color of customers, the experimental results and their proportion are used in the production line. This machine is one of the important experimental equipment in the rubber and plastic industry.

Product Parameter

| Model | 3inch | 6inch | 8inch |

| Drum Diameter(mm) | 120 | 150 | 190 |

| Roller Length(mm) | 360 | 500 | 600 |

| Roller Pitch(mm) | 0-6 | 0-8 | 0-10 |

| Two Rolling Speed Ratio | 01:01.2 | 01:01.3 | 01:01.2 |

| Front Rolling Speed (rev/min) | 18 | 18 | 19 |

| Rear Rolling Speed (rev/min) | 21.5 | 21.5 | 23 |

| Primary yield ( kg ) | 1 | 5-8 | 10-15 |

| Reducer model | GH-28 | ZQ250 | ZQ250 |

| Power (kw) | 0.75 | 3 | 5.5 |

| Rotation speed (rev/min) | 1440 | 960 | 1440 |

| Machine weight (kg) | 200 | 700 | 800 |

| Size (mm) | 800*600*1000 | 1500*700*1100 | 2000*800*1150 |

Purchase Notes:

1. The open mill is divided into two types of water cooling (for rubber) and electric heating (for plastic). It is also necessary to explain different rubber materials.

2. The open mill can directly make pellets, powders, and sheets into tablets, and customers can mix different colors and different types of pellets.