2.

New technology gear box: High torque gear box, one body design, two cooling system.

3.

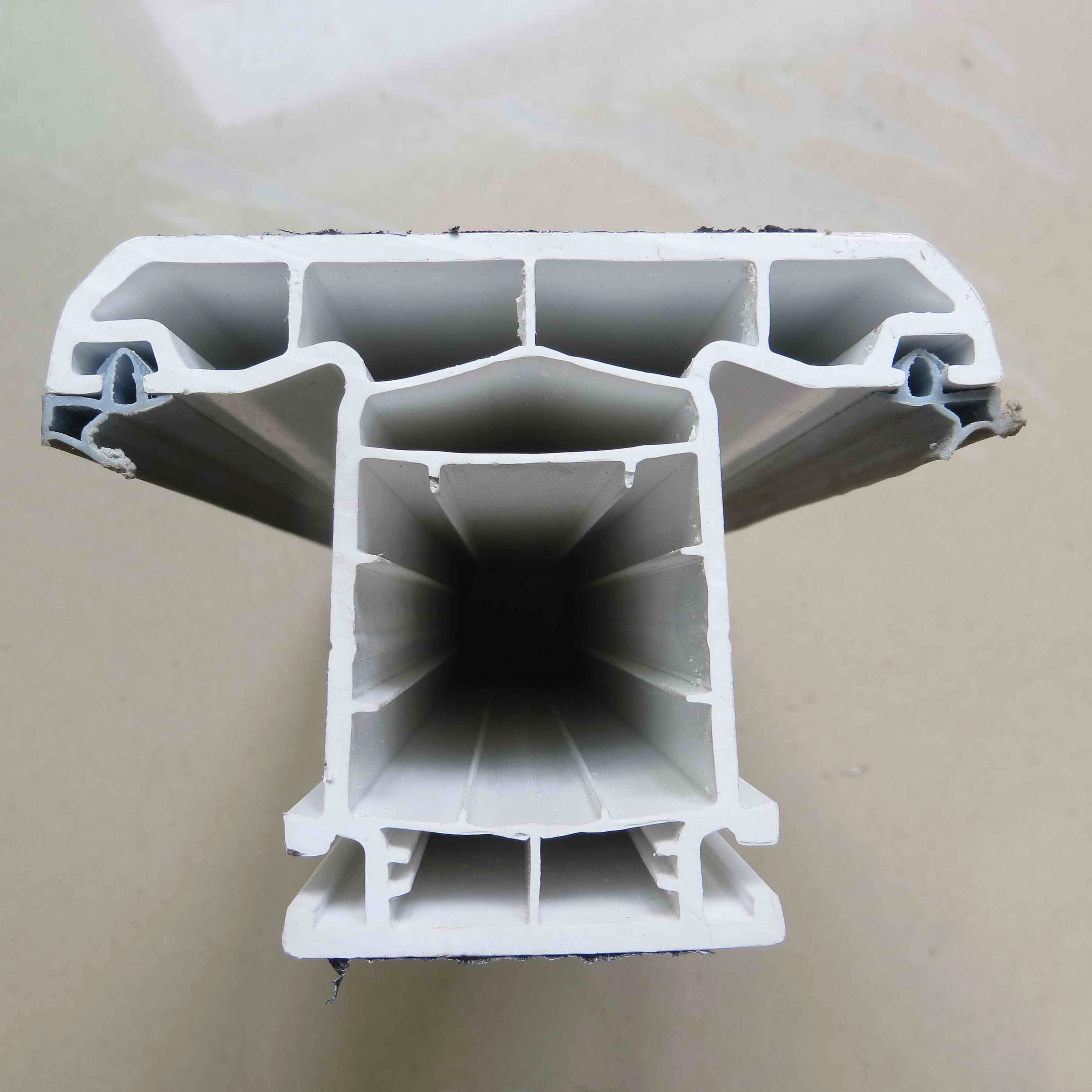

Screw and barrel: Bi-metal material ensure longer working life, ensuring running non-stop 24 hours /day.

4.

Energy saving heater: Heater on the barrel is energy saving type by 15%.

5.

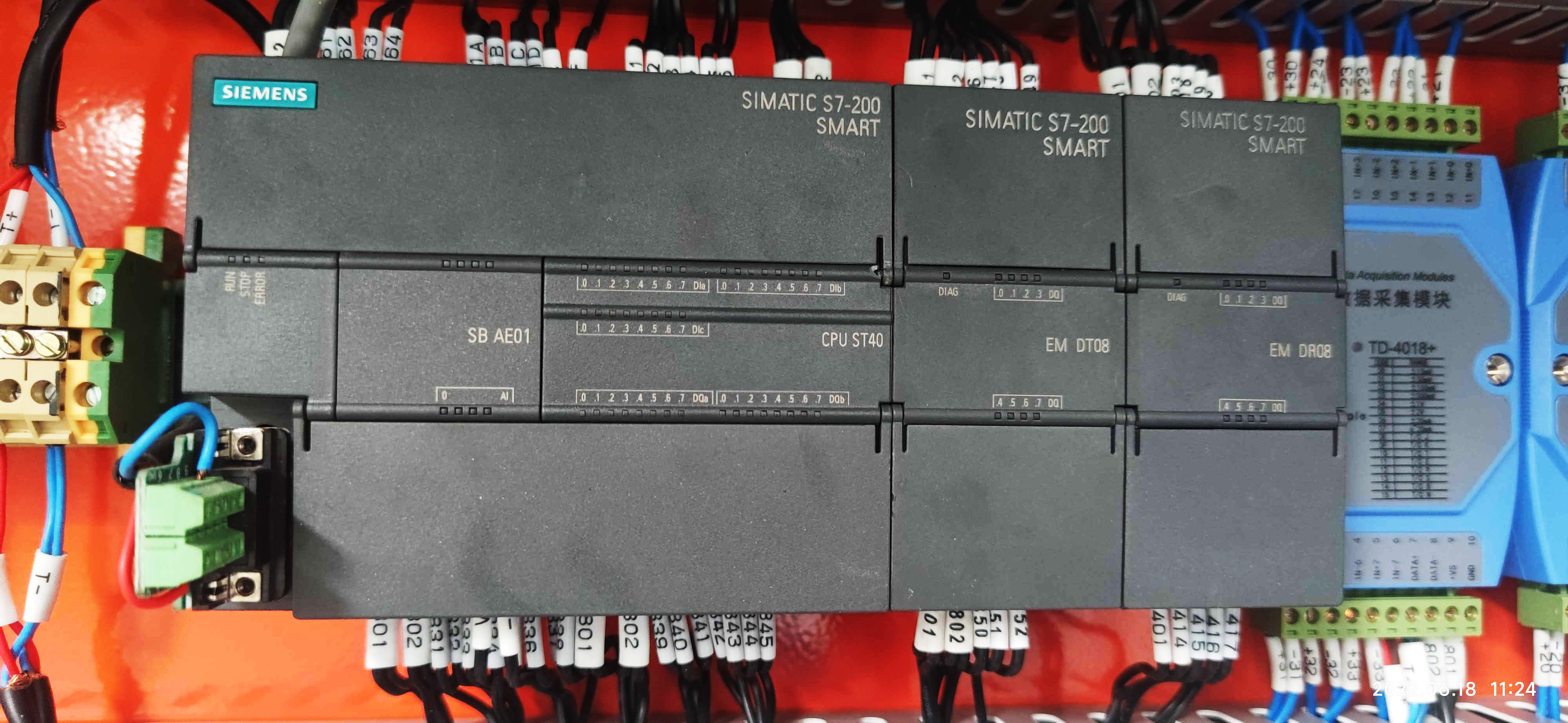

Electric elements and box: In detachable, with world famous brand such ABB, Siemens, Schneider, Delta, well organized.

6.

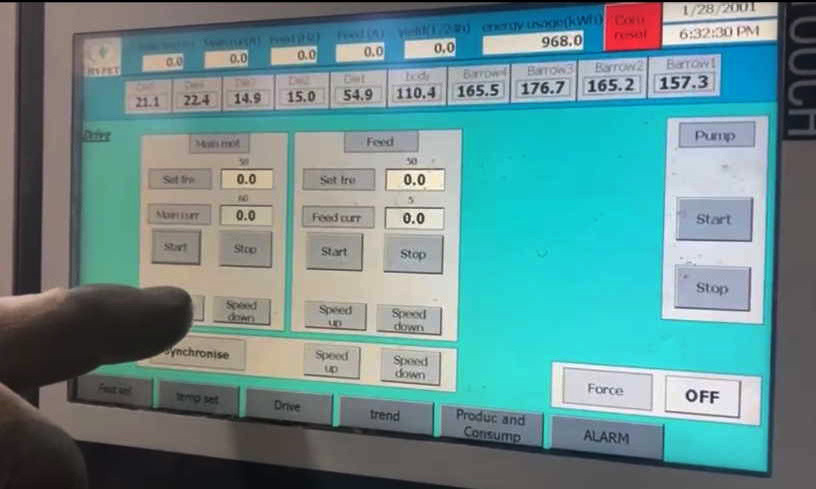

HYPET PLC control system: With operation easy, management full, energy saving and counting, and intelligent control system.

7.

Pipe brighten device: To make the pipe shining and smoothing.

8.

Vacuum tank stainless steel 304: Water level and temperature controlled automatically.