- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

320 mm

-

Width of Working Table (mm):

-

900 mm

-

Dimension:

-

customized

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

ACRROS

-

Year:

-

new

-

Weight (KG):

-

2000

-

Motor Power (kw):

-

11 kw

-

Certification:

-

ce

-

Raw Material:

-

Sheet / Plate Rolling

-

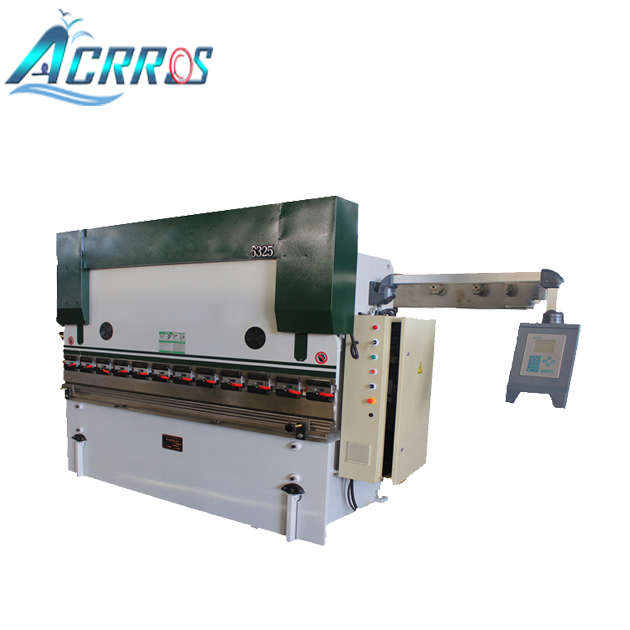

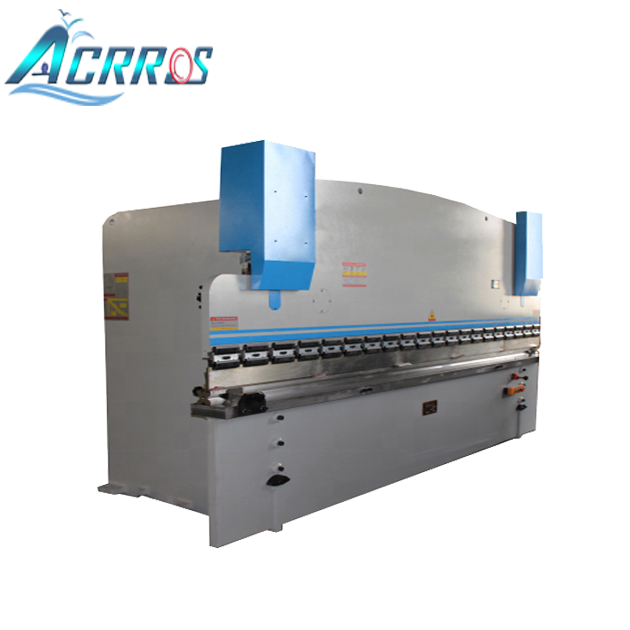

Product name:

-

Press Brake

-

Type:

-

Hydraulic Bending Tools

-

Application:

-

Stainless Plate Bending

-

Function:

-

Steel Metal Bending

-

Name:

-

bending machine

-

Usage:

-

Metal Sheet Rolling Cutting Bending

-

Keyword:

-

hydraulic bending machine

Quick Details

-

Machine Type:

-

Synchronized

-

Length of Working Table (mm):

-

5000

-

Slider Stroke (mm):

-

250 mm

-

Throat Depth (mm):

-

320 mm

-

Width of Working Table (mm):

-

900 mm

-

Dimension:

-

customized

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

ACRROS

-

Year:

-

new

-

Weight (KG):

-

2000

-

Motor Power (kw):

-

11 kw

-

Certification:

-

ce

-

Raw Material:

-

Sheet / Plate Rolling

-

Product name:

-

Press Brake

-

Type:

-

Hydraulic Bending Tools

-

Application:

-

Stainless Plate Bending

-

Function:

-

Steel Metal Bending

-

Name:

-

bending machine

-

Usage:

-

Metal Sheet Rolling Cutting Bending

-

Keyword:

-

hydraulic bending machine

Please kindly click here for talking!

I'm definitely provide the most suitable press brake bending machine for you!

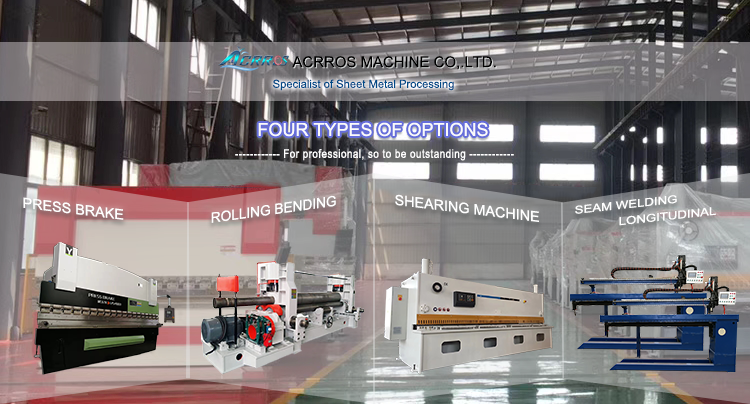

Model WC67Y/K SERIES Technical Parameters of Press Brake

| Model |

Nominal Force (KN) |

Worktable Length (mm) |

Throat Depth (mm) |

Slider Travel (mm) |

Max.Open (mm) |

Power (kw) |

| 63/2500 | 630 | 2500 | 250 | 100 | 340 | 5.5 |

| 100/2500 | 1000 | 2500 | 320 | 120 | 340 | 7.5 |

| 125/3200 | 1250 | 3200 | 320 | 120 | 340 | 7.5 |

| 160/3200 | 1600 | 3200 | 320 | 200 | 470 | 11 |

| 200/3200 | 2000 | 3200 | 320 | 200 | 500 | 11 |

Model QC11/12Y/K SERIES Technical Parameters of Shearing Machine

| Model |

Cutting thickness (mm) |

Cutting Length (mm) |

Cutting Angle (°) |

Travel Times (times/min) |

Stopper range (mm) |

Power (kw) |

| 4x2500 | 4 | 2500 | 1°30‘ | 28 | 20-500 | 4 |

| 6x2500 | 6 | 2500 | 1°30‘ | 18 | 20-600 | 7.5 |

| 8x3200 | 8 | 3200 | 1°45‘ | 10 | 20-600 | 11 |

| 12x3200 | 12 | 3200 | 2° | 10 | 20-800 | 22 |

| 16x3200 | 16 | 3200 | 2° | 10 | 20-800 | 22 |

ACRROS press brake is a machine pressing tool for bending sheet and plate material, most commonly sheet metal. It forms predetermined bends by clamping the workpiece between a matching punch and die.

Typically, two C-frames form the sides of the press brake, connected to a table at the bottom and on a movable beam at the top. The bottom tool is mounted on the table, with the top tool mounted on the upper beam.

Hydraulic press brake operates by means of two synchronized hydraulic cylinders on the C-frames moving the upper beam.

Servo-electric brakes use a servo-motor to drive a ballscrew or belt drive to exert tonnage on the ram. Servo-electric machines are typically used in lower tonnage applications. Hydraulic brakes produce accurate high quality products, are reliable, use little energy and are safer because, unlike flywheel-driven presses, the motion of the ram can be easily stopped at any time in response to a safety device, e.g. a light curtain or other presence sensing device.

ACRROS bending machine is a forming machine tool. Its purpose is to assemble a bend on a workpiece. A bends is manufactured by using a bending tool during a linear or rotating move.

ACRROS CNC bending machines are developed for high flexibility and low setup times. Those machines are able to bend single pieces as well as small batches with the same precision and efficiency as series-produced parts in an economical way.

ACRROS bending machines can be constructed to adjust the bending angle by reference, stroke measurement or angle measurement.

ACRROS high-tonnage hydraulic press breaks a high bending accuracy starting with the first work piece.