Screw&Barrel:ZhoushanScrew&Barrel material:38CrMoAlA

Electrical control system: ABB inverter, Schneider Contactor, Siemens switch, Siemens PLC control system, Siemens touch

screen, Omron/RKC temperature controller

Gearbox:Duoling Jiangyin/Guomao

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

SHN

-

Brand Name:

-

Rainbow

-

Voltage:

-

380V, 415V, 440V

-

Dimension(L*W*H):

-

20*2*3M

-

Power (kW):

-

30

-

Weight:

-

9000 KG

-

Raw material:

-

PE granular

-

Inverter:

-

ABB

-

Motor:

-

SIEMENS Brand

-

Contactor:

-

Schnerder

-

Extruder numbers:

-

According to pipe layers

-

Marketing Type:

-

Hot Product 2022

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

33:1

-

Screw Speed (rpm):

-

39.1 rpm

-

Place of Origin:

-

SHN

-

Brand Name:

-

Rainbow

-

Voltage:

-

380V, 415V, 440V

-

Dimension(L*W*H):

-

20*2*3M

-

Power (kW):

-

30

-

Weight:

-

9000 KG

-

Raw material:

-

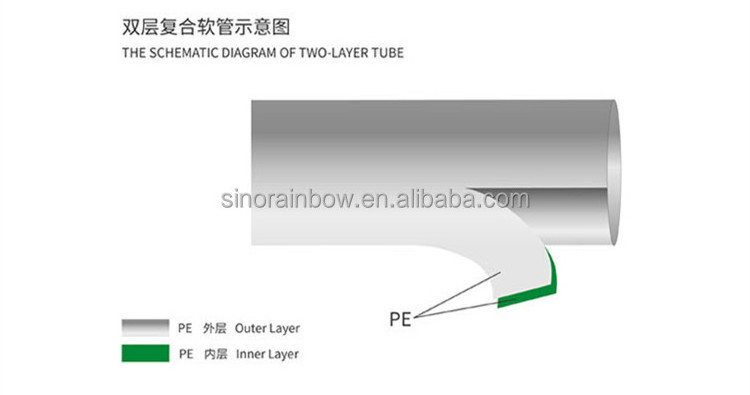

PE granular

-

Inverter:

-

ABB

-

Motor:

-

SIEMENS Brand

-

Contactor:

-

Schnerder

-

Extruder numbers:

-

According to pipe layers

-

Marketing Type:

-

Hot Product 2022

Product Overview

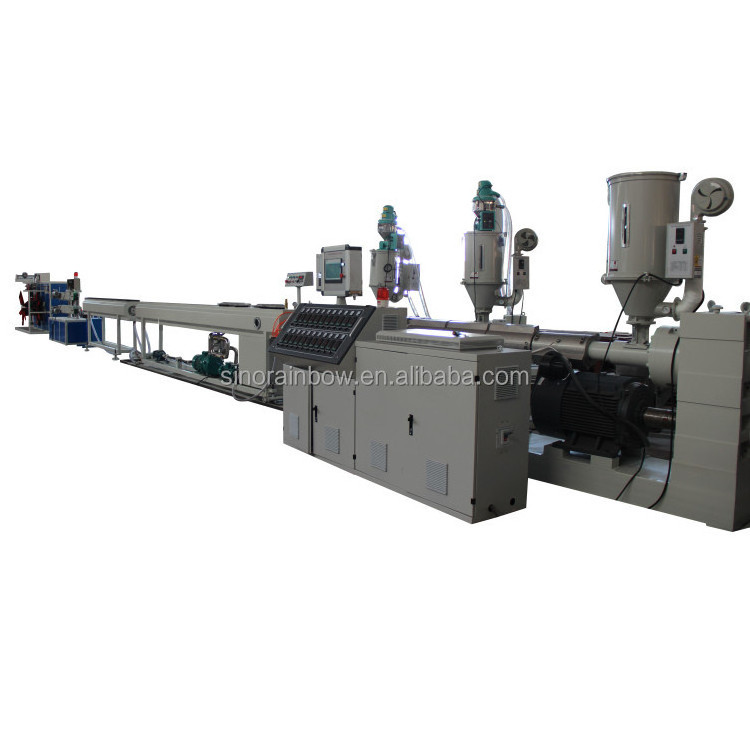

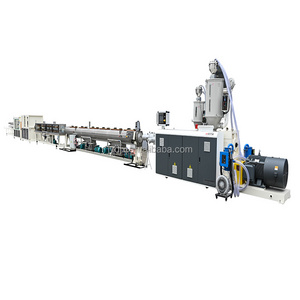

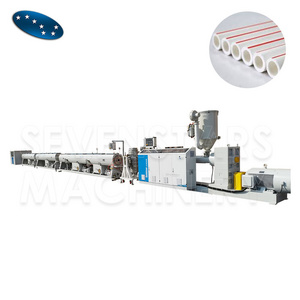

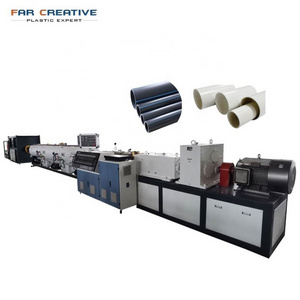

2Layer 5Layer Cream Cosmetic Tube Plastic PE Pipe Extrusion Making Machine

Qingdao Rainbow Intelligent Equipment is a professional plastic extrusion machine manufacturer with more than 15 years experience. We make a lot of research and innovation. Our machines have many advantages, such as uniform plasticizing mixing ,high output, stable quality, wide range of adaption, long service life.

This line is designed to produce PPR HDPE pipe, with high-efficiency single screw extruder, the structurer of the screw for our extruder improved after repeated experimental tests, chieve maximum production while ensuring the plasticizing effect of the pipe.

PRODUCT SPECIFICATIONS

|

2Layer 5Layer Cream Cosmetic Tube Plastic PE Pipe Extrusion Making Machine

|

|

|

||

|

1

|

Single screw extruder

|

2-4Sets

|

||

|

2

|

Mould/Die

|

One Set

|

||

|

3

|

Vacuum Calibration Cooling Tank

|

One Set

|

||

|

4

|

Haul-off

|

One Set

|

||

|

5

|

Cutter

|

One Set

|

||

|

6

|

Stacker

|

One Set

|

||

Plastic pipe die including bas extrusion die, core die & mouth die, sizing sleeve, heater etc.

Usually the extrusion die material is 40Cr.

Sizing sleeve material copper.

Heater is made of cast-aluminum plate heater.

Usually the extrusion die material is 40Cr.

Sizing sleeve material copper.

Heater is made of cast-aluminum plate heater.

Tank materials: 6mm 304 S. S.Materials Water temperature and level controlling technology;

High pressure and stable water jet.

Pressure protection design

Pressure protection design

Vacuum pump power : 5.5 kw

Material: Stainless steel

Diameter: Depends on final pipe diameter

Diameter: Depends on final pipe diameter

(1) Driving motor power: 2.2 kw

(2) Transducer: Siemens transducer

(3) hauling track type:110 plastic block

(4) Pressing method:Pneumatic pressing

(5) Effective clamping length:1800 mm

(6)Speed driving and control: ABB inverter

(6)Speed driving and control: ABB inverter

(1) Motor power: 3 kw

(2) Method: Saw cutting

(3) Cutting scope: Customized

(4) PLC control system, using meter counter or sensor switch for the setting of desired length.

(3) Cutting scope: Customized

(4) PLC control system, using meter counter or sensor switch for the setting of desired length.

Electric System

ABB inverter, Schneider Contactor, Siemens switch, Siemens PLC control system, Siemens touch

screen, Omron/RKC temperature controller

screen, Omron/RKC temperature controller

Successful Project

Customer Factory

Customer Factory

Customer Factory

Certifications

Delivery

Contacts

FAQ

Q1: Your company is a trading company or a machine manufacturer?

A1: Our company is a plastic machinery manufacturer which is engaged into this trade more than 15 years.As a manufacturer,we could supply our machine,service,technical support and maintenance directly and it's more convenient.

Q2: How to get an accurate offer?

A2: Because our offer and technical specification is associated with your final product and requested capacity, we will choose the right model of extruder and mould after understanding all the information, then we could supply our plan.We could fully exchange information by Email, whatsapp or wechat.

Q3: Where is your factory and which port is the nearest to your factory?

A3: My factory is in Qingdao city, Shandong Province and the nearest seaport is Qingdao port.

Q4: How long is the delivery time?

A4: Generally it will take 30-45 days.

Q5: Could you send your engineers to our factory?

A5: Yes,we will send our engineers to your factory for installation,commissioning and training after machines arrive at your

factory. In addition, if you need our engineers available in the future, we also could send our engineers.

If you have any questions, please do not hesitate to contact us. We Look forward to listening to you!

A1: Our company is a plastic machinery manufacturer which is engaged into this trade more than 15 years.As a manufacturer,we could supply our machine,service,technical support and maintenance directly and it's more convenient.

Q2: How to get an accurate offer?

A2: Because our offer and technical specification is associated with your final product and requested capacity, we will choose the right model of extruder and mould after understanding all the information, then we could supply our plan.We could fully exchange information by Email, whatsapp or wechat.

Q3: Where is your factory and which port is the nearest to your factory?

A3: My factory is in Qingdao city, Shandong Province and the nearest seaport is Qingdao port.

Q4: How long is the delivery time?

A4: Generally it will take 30-45 days.

Q5: Could you send your engineers to our factory?

A5: Yes,we will send our engineers to your factory for installation,commissioning and training after machines arrive at your

factory. In addition, if you need our engineers available in the future, we also could send our engineers.

If you have any questions, please do not hesitate to contact us. We Look forward to listening to you!

Hot Searches