The model of the dust collector is varies depending on the case of use.We use the imported coating materials as the filter material in dust collector,the filter aperture’s size should less than 0.5 microns, which is the most advanced filter material in the world.

The service life can be extended to more than 10 years and don’t need to change if choose the sintered filter.

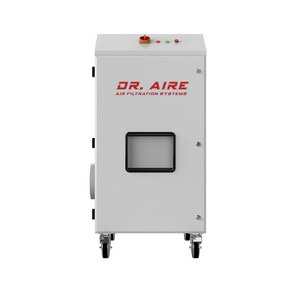

The main features:

1.The equipment has 304 stainless steel modular structure, removable cleaning and maintenance is extremely convenient.

2.Beautiful appearance, unique shape, good sealing performance.

3. The materials and the air is separated by the filter materials with good ventilation and high separation efficiency, prevent the fine material powder into the pump and pollute the surrounding environment effectively.

4.Anti-blowing gas tank and back-flush valve can be set according to the cycle of filter’s automatic backwash cleaning, high anti-blowing ability, high efficiency of back-flush.

The service life can be extended to more than 10 years and don’t need to change if choose the sintered filter.

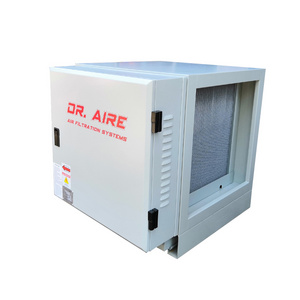

The main features:

1.The equipment has 304 stainless steel modular structure, removable cleaning and maintenance is extremely convenient.

2.Beautiful appearance, unique shape, good sealing performance.

3. The materials and the air is separated by the filter materials with good ventilation and high separation efficiency, prevent the fine material powder into the pump and pollute the surrounding environment effectively.

4.Anti-blowing gas tank and back-flush valve can be set according to the cycle of filter’s automatic backwash cleaning, high anti-blowing ability, high efficiency of back-flush.